Prediction method for piston cutting deformation based on BP neural network

A BP neural network and cutting processing technology, applied in neural learning methods, biological neural network models, instruments, etc., can solve the problems of unrealistic real-time prediction, low computing efficiency, and large computing resources consumption, so as to improve the establishment efficiency, The effect of high reliability and shortened forecast time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

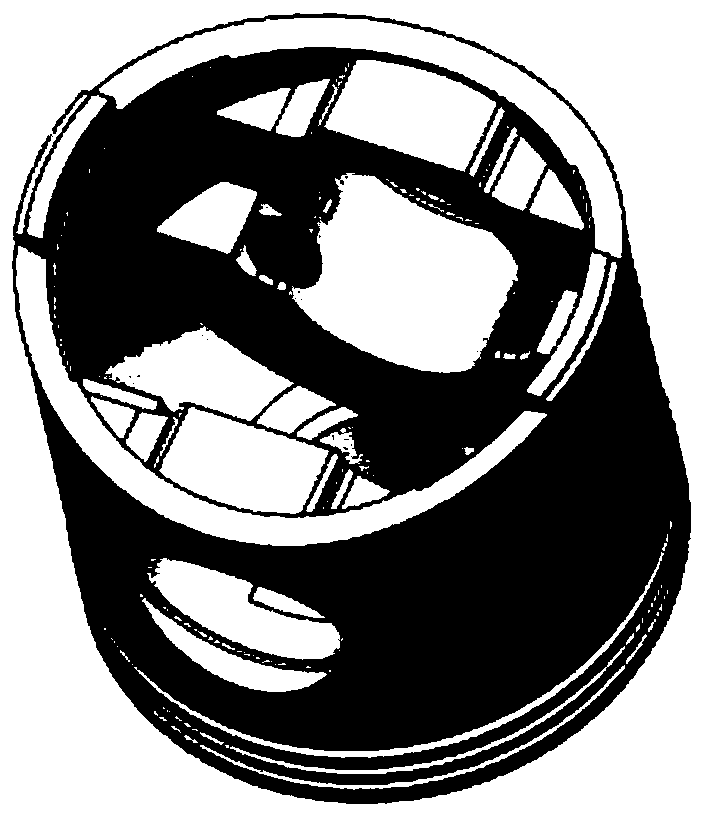

[0018] The mechanism of the cutting deformation of the piston is that the blank of the part containing the initial residual stress, under the combined influence of factors such as clamping force load, cutting force load, cutting heat load and the change of constraint conditions caused by a large amount of material removal, its internal stress The field gradually evolves, and after the processing is completed and the clamping is removed, the internal stress field further evolves and causes the deformation of the part, and finally reaches the state of internal stress self-balance. In order to predict and analyze the deformation of the piston cutting process, it is necessary to track the evolution process of the internal stress field under the action of the outside world, and to process the data through efficient computing means to obtain the final machining deformation.

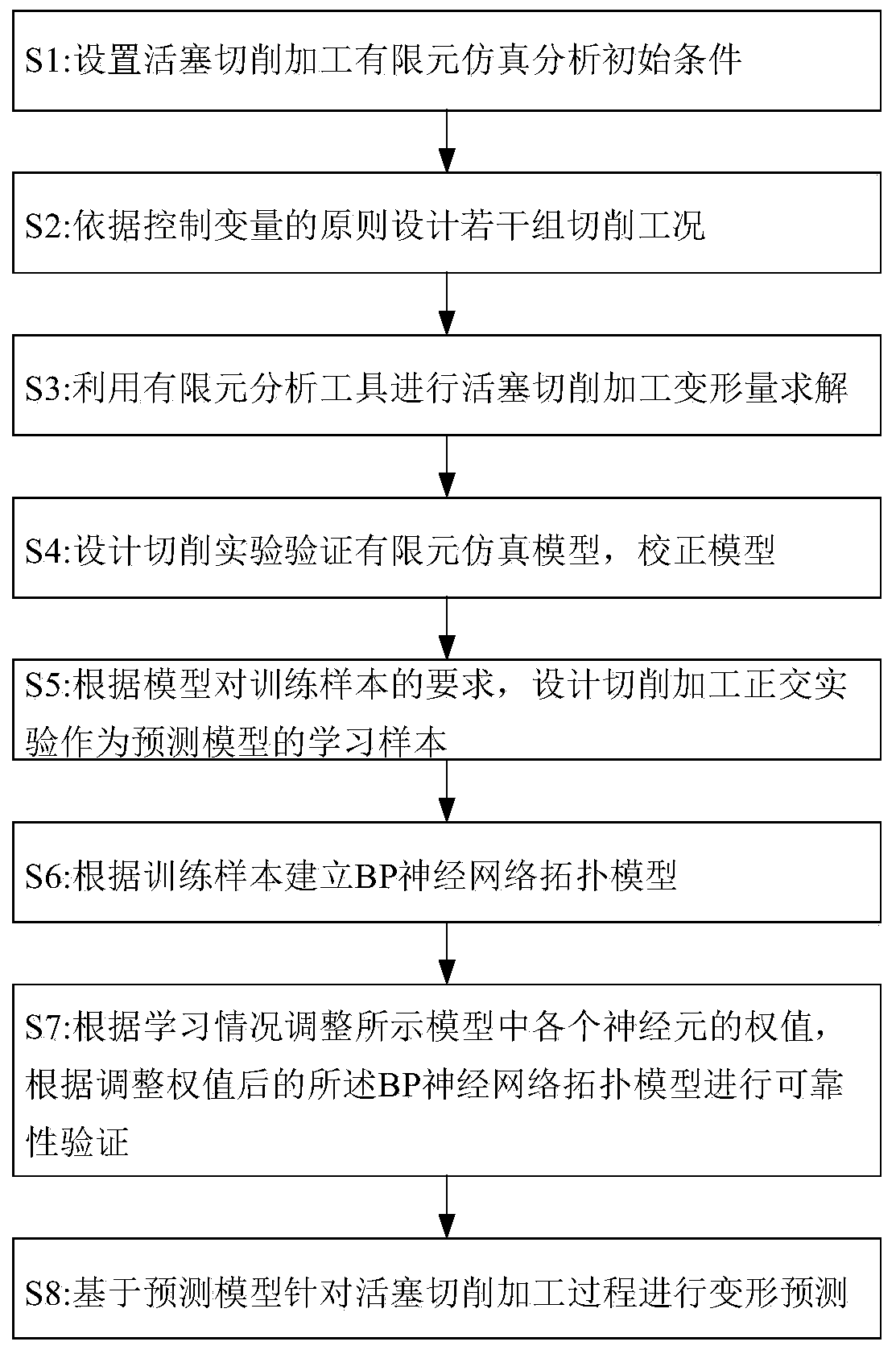

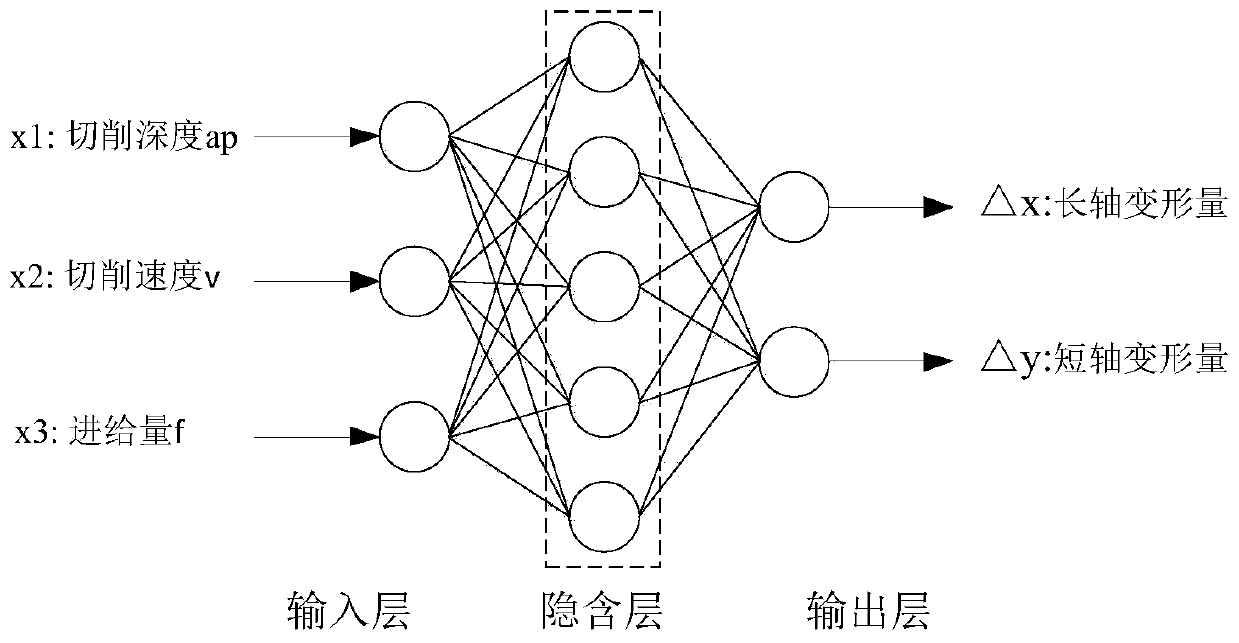

[0019] Such as figure 1 As shown, this example predicts the processing deformation for the rough boring cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com