Embedded disk motor stator coil assembling apparatus control system

A control system and disc motor technology, applied in the control system, the control of the speed or torque of the motor, and the manufacture of motor generators, etc. Signal detection module monitoring and other issues, to achieve the effect of low cost, reduced failure rate, and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

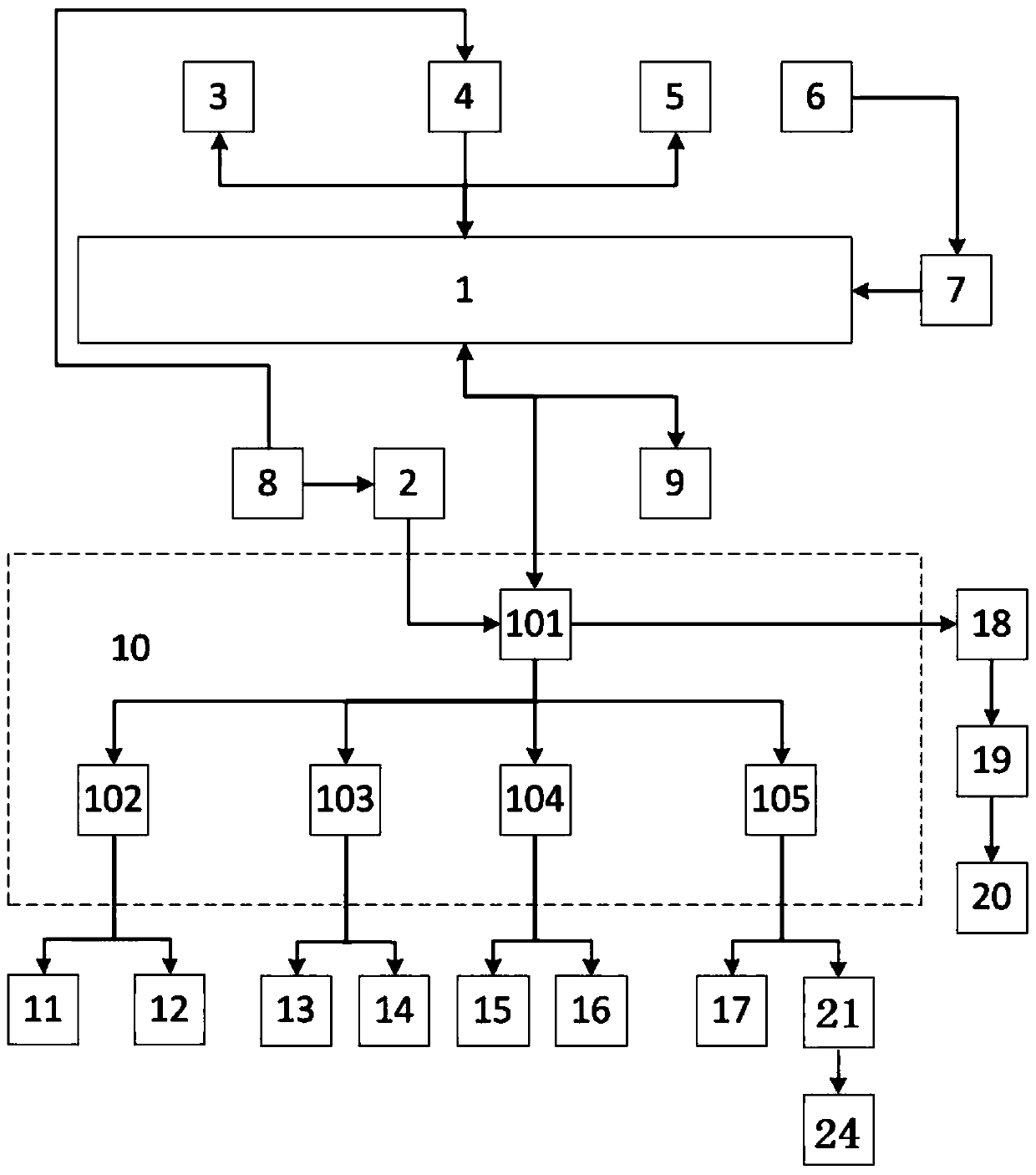

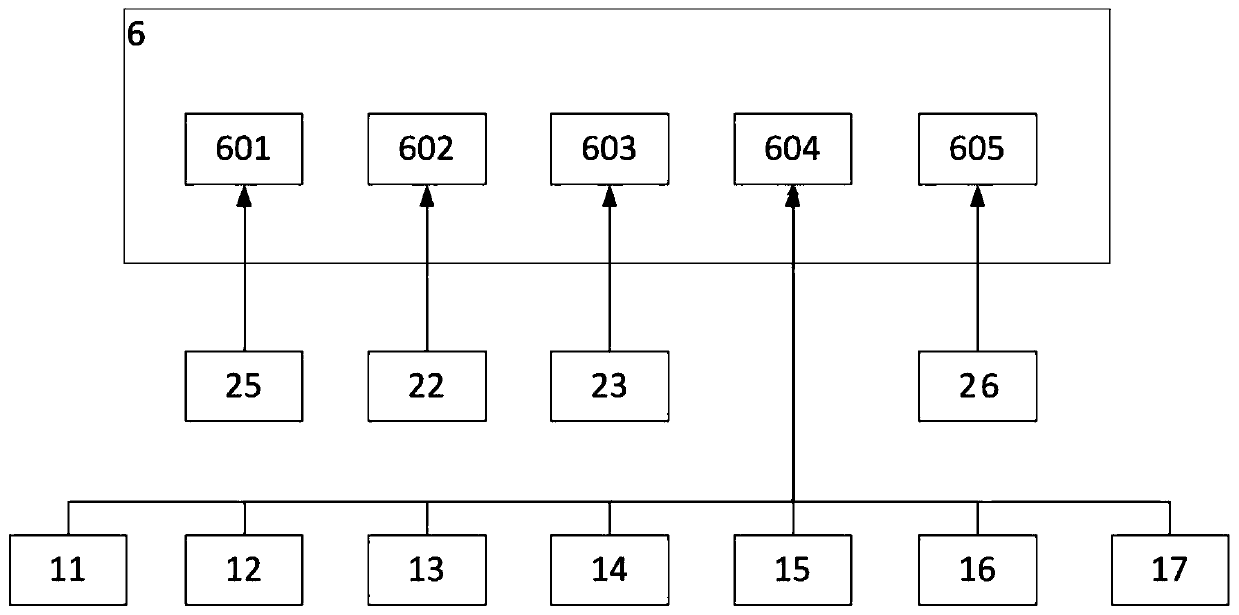

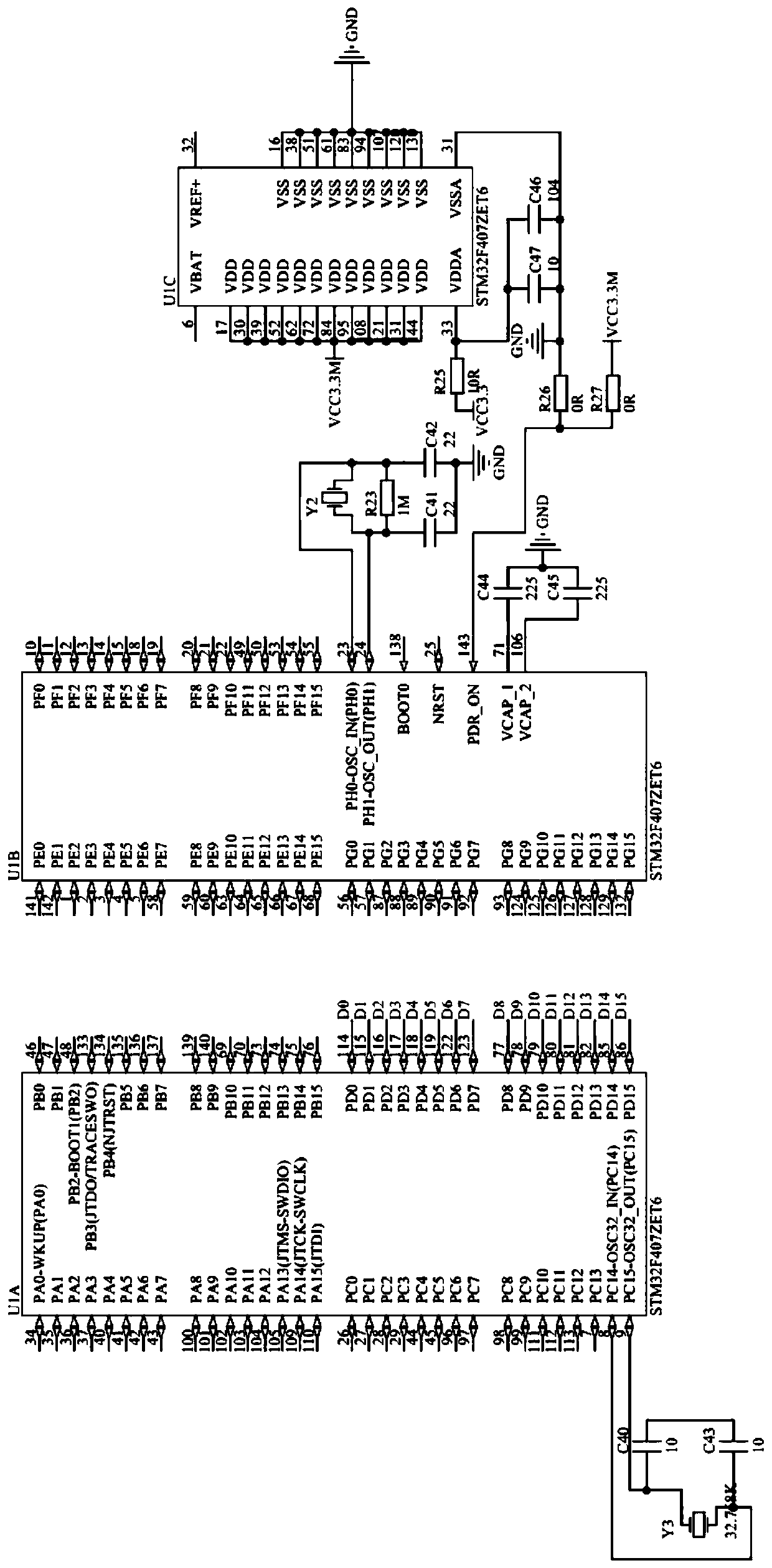

[0027] The invention provides a control system based on an embedded disc motor stator wire inserting machine (control system for short), which is characterized in that the control system includes a single-chip microcomputer 1, an FPGA module analog power input circuit 2, a single-chip power conversion module 4, a human Machine interaction module 5, signal detection module 6, input switch signal optocoupler isolation circuit 7, FPGA power conversion module 8, data storage module 9 and FPGA module 10; Said FPGA module 10 includes FPGA chip 101, first motor drive circuit 102 , the second motor drive circuit 103, the third motor drive circuit 104 and the fourth motor drive circuit 105;

[0028] The single-chip microcomputer 1 is electrically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com