Hologram reproduction method and device

一种设备、全息光学元件的技术,应用在全息图复制和全息图复制设备领域,能够解决不适用大规模生产等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

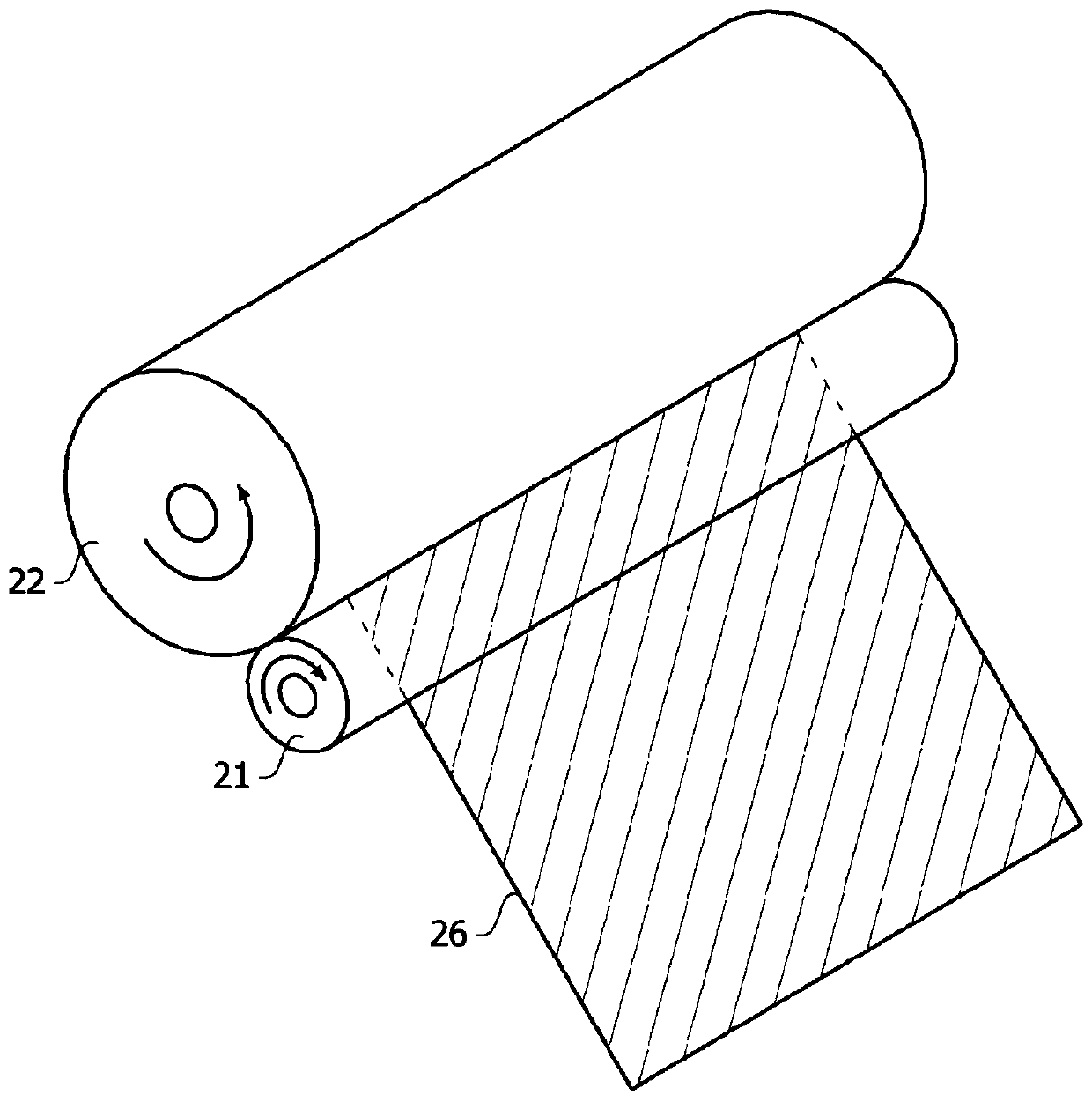

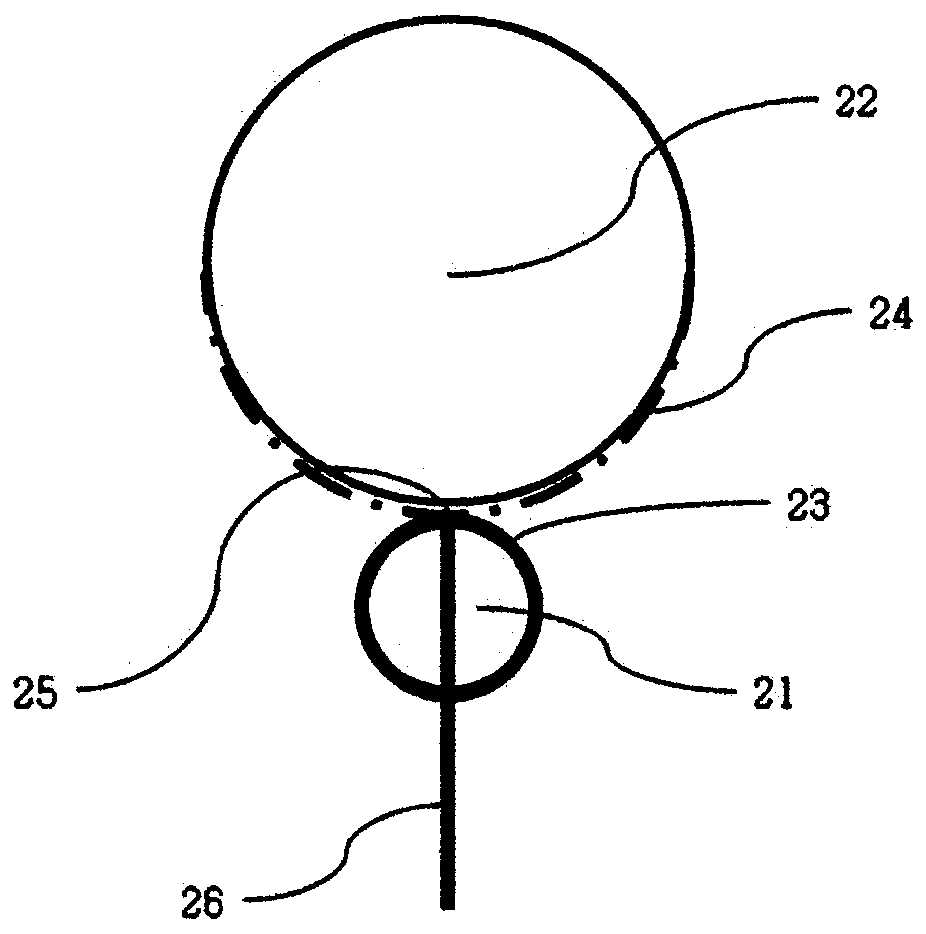

[0073] As shown in FIG. 2, a master roll (21) having a master plate (23) formed on its surface as a diffractive optical element having predetermined optical characteristics and a black-series photosensitive material (24) in a state of being adhered to the surface were used. ) of the main roll (22) to manufacture transmission-type holographic elements.

[0074] Specifically, after the photosensitive material (24) is adhered to the surface of the main roll (22) by a laminating roll (not shown) heated to about 50° C., the photosensitive material is transported so that it can face the surface of the main roll (22) formed on the main roll. Master (23) on (21). At this time, the photosensitive material (24) is conveyed by the main roller (22) at a speed of about 1.5 m / min. On the other hand, a master (23) was formed on the surface of a master roll (21) having a diameter of 10 cm. In the state where the master and the photosensitive material face each other while being in contact w...

experiment example 2

[0076] The method of the present application was carried out in the same manner as in the examples, except that the line width of the laser line beam used was 3 mm.

[0077] Evaluation of the replicated holographic optical elements

[0078] The diffraction efficiencies of the transmission holograms produced in each example are shown in Figure 4 middle. exist Figure 4 , the horizontal axis represents the incident angle (degrees, °) of the incident light incident on the photosensitive material on which the hologram is recorded, and the vertical axis represents the diffraction efficiency (%) of the diffracted light relative to the incident light. Diffraction efficiency is calculated by the following equation.

[0079] [Equation] Diffraction Efficiency = Diffraction Light Intensity / (Diffraction Light Intensity+Transmitted Light Intensity)

[0080] Such as Figure 4 As shown, in the case of Experimental Example 1 using a line beam with a line width of 1 mm, the diffraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com