Driving structure and device with flexible joint

A technology of flexible joints and driving structures, applied in the field of medical devices, can solve problems such as large operating space, and achieve the effects of good comfort, convenient processing and manufacturing, and stable hinge structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

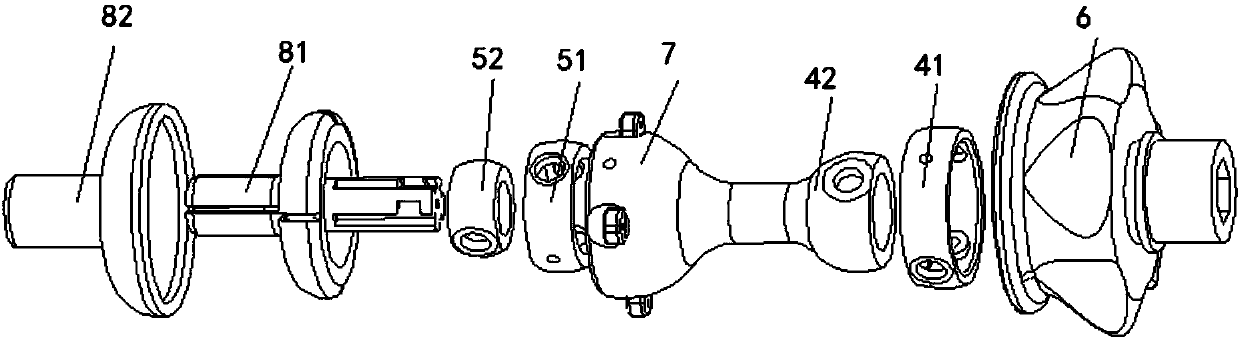

[0048] The driving structure 9 of the present embodiment, such as figure 1 , image 3 , Figure 4 As shown, it is suitable for application in devices with flexible joints, and the device with flexible joints includes flexible joints 33 and a grip part 2 . The driving structure 9 includes a driving body 1 and a control line 10 .

[0049] The driving body 1 is arranged between the flexible joint 33 and the grip part 2, and its two ends are respectively connected with the flexible joint 33 and the grip part 2, and the two ends of the driving body 1 can be relatively deflected.

[0050] One end of the control wire 10 is connected to an end of the flexible joint 33 away from the driving body 1 , and the other end is connected to the driving body 1 . The two ends of the driving body 1 deflect relative to each other, and the distance between the connection between the flexible joint 33 and the control wire 10 and the connection between the driven body 1 and the control wire 10 cha...

Embodiment 2

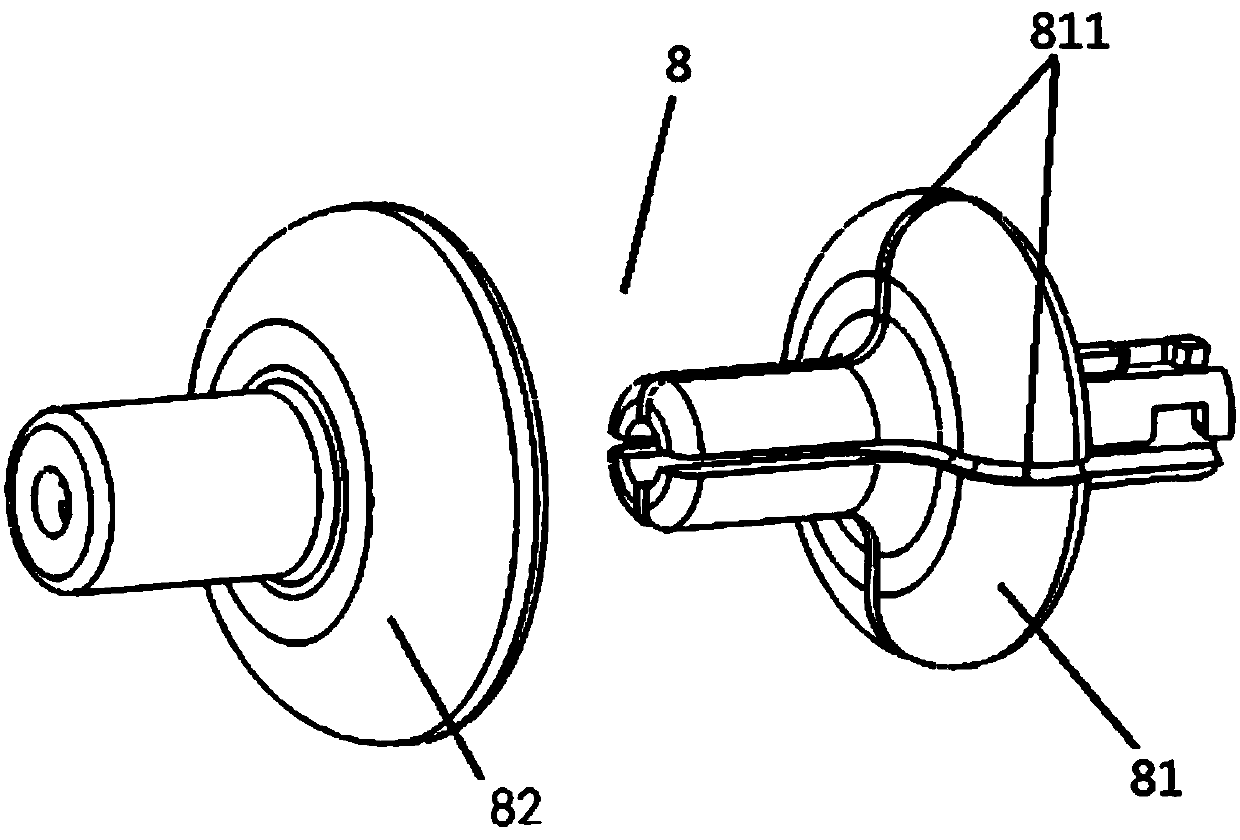

[0062] In this embodiment, on the basis of Embodiment 1, the driving structure 9 also includes a runner 6, which is rotatably connected to the grip part 2, and can drive the driving body 1 to rotate around the axis of the driving body 1, and the driving body 1 passes through the first Hinged shaft and runner 6 are hinged. In order to make the rotation speed of the runner 6 consistent with the rotation speed of the actuator, the axis of the runner 6 coincides with the axis of the actuator 3 .

[0063] In this embodiment, the specific structure is that the first hinge member 51 is hinged in the runner 6 through the first hinge shaft.

Embodiment 3

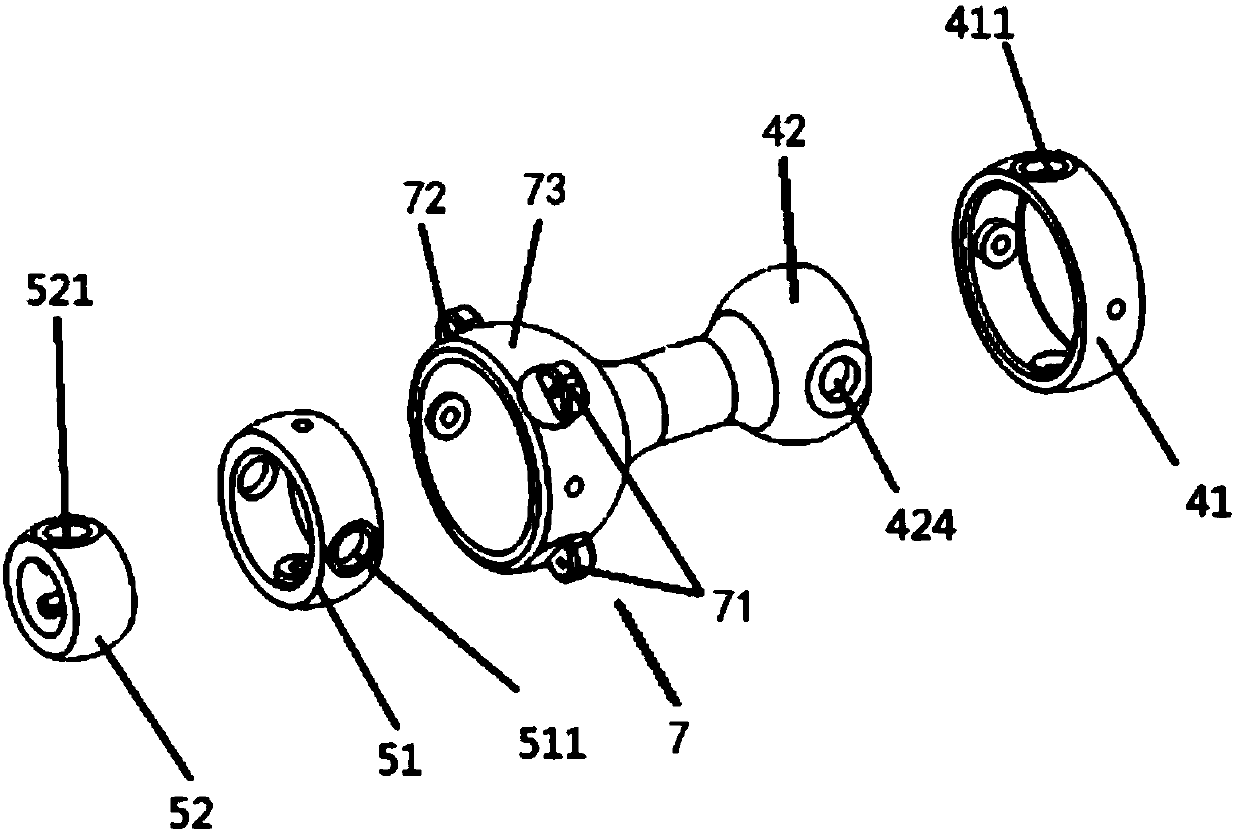

[0065] This embodiment is on the basis of embodiment 1, as figure 2 , Figure 5 , Figure 6 As shown, the driving body 1 further includes a second Hooke hinge structure 4 disposed between the first Hooke hinge structure 5 and the grip part 2 . The second Hookee hinge structure 4 includes a third hinge part 41 and a fourth hinge part 42 . The third hinge 41 is provided with a third hinge hole 411, the third hinge hole 411 is provided with a third bearing whose axis coincides with the axis of the third hinge hole 411, and the third hinge shaft is arranged on the third hinge through the third bearing. 41, the third hinge member 41 is hinged in the grasping part 2 through the third hinge shaft. One end of the fourth hinge 42 is provided with a fourth hinge hole 424, the fourth hinge hole 424 is provided with a fourth bearing whose axis coincides with the axis of the fourth hinge hole 424, and the fourth hinge shaft is arranged on the fourth hinge through the fourth bearing. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com