A display device and its manufacturing method

A technology for display devices and quantum dots to emit light, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., and can solve problems such as carrier injection imbalance, low efficiency and lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

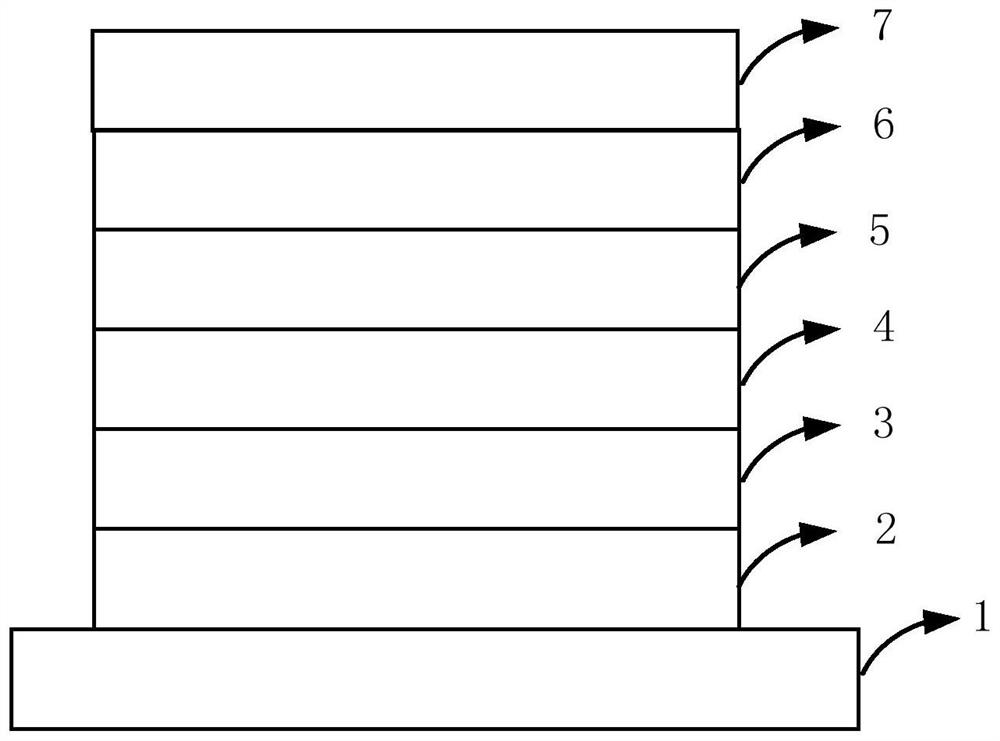

[0029] An embodiment of the present invention provides a method for manufacturing a display device, which is used to prepare a display device corresponding to the previous embodiment.

[0030] Specifically, when the prepared display device is a positive structure device, the preparation method includes the following steps:

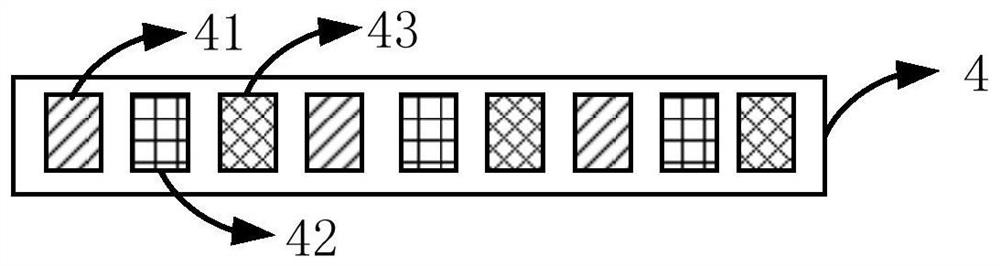

[0031] Step S11: Provide a prefabricated device, and deposit red quantum dots, green quantum dots, and blue quantum dots on the prefabricated device to form a quantum dot light-emitting layer.

[0032] In the embodiment of the present invention, the provided prefabricated device may include a substrate, an anode, and the quantum dot luminescent layer is deposited on the anode; or include a substrate, an anode, and a hole functional layer, and the quantum dot luminescent layer is located on the hole functional layer, The hole functional layer may be at least one of a hole injection layer and a hole transport layer.

[0033] Step S12: Depositing a composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com