360-degree rotary assembling light rail system device and workpiece assembling method thereof

A system device, light rail technology, applied in the direction of workbench, metal processing, manufacturing tools, etc., can solve problems such as unrealizable products, and achieve the effects of safety, precision, high security, and strong flexibility and scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

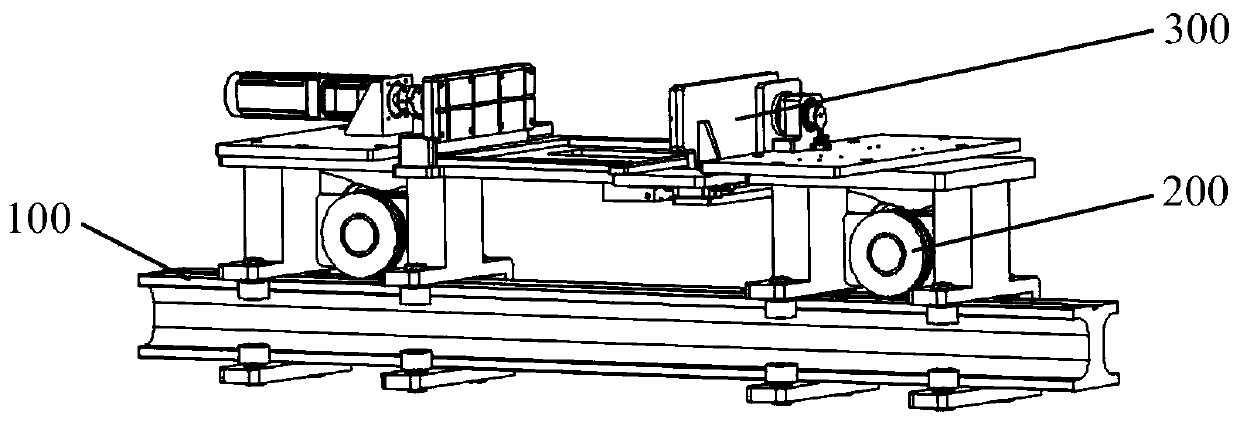

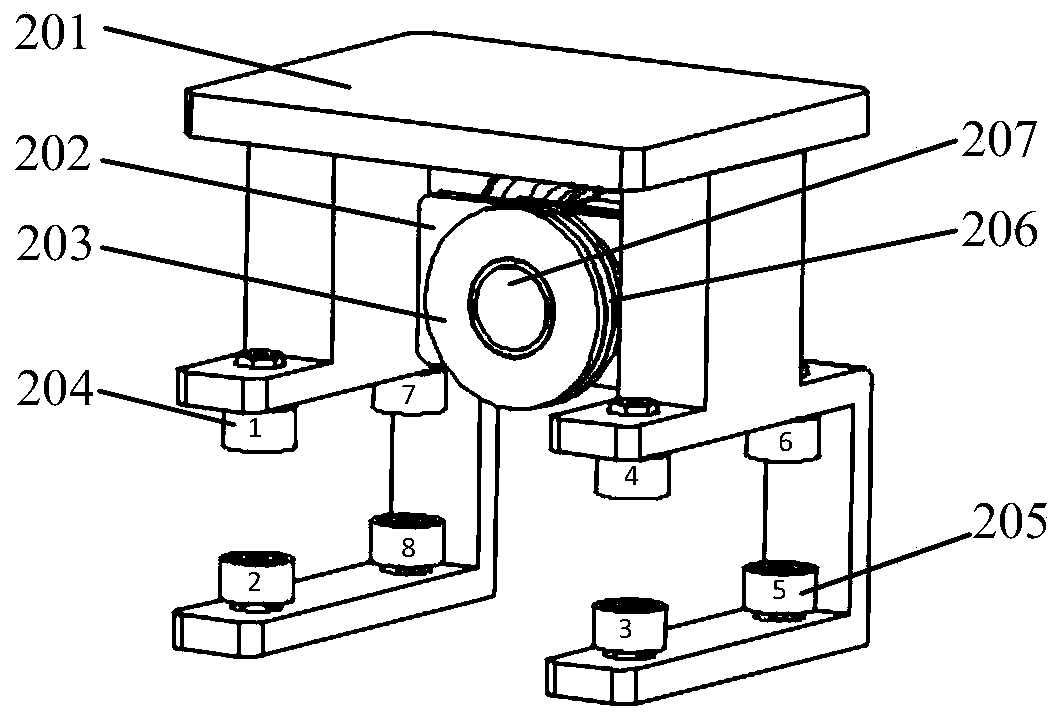

[0053] see figure 1 , a 360-degree rotating assembly light rail system device, including a light rail unit 100, a moving unit 200, a 360-degree workpiece rotating unit 300 and a sensing unit 400. The 360-degree workpiece rotation unit 300 is fixedly installed on the mobile unit 200 by bolts, and the mobile unit 200 is assembled on the light rail unit 100, so that the workpiece loaded on the 360-degree workpiece rotation unit 300 can move freely along the light rail unit 100.

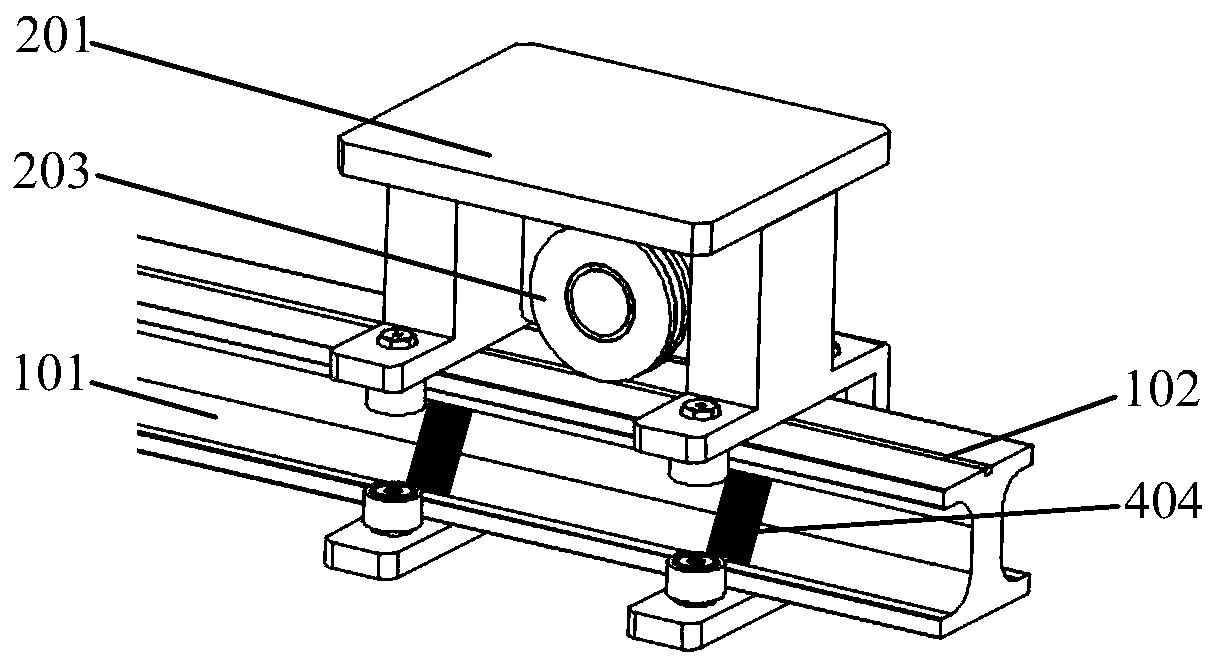

[0054] see figure 2 , the light rail unit 100 is composed of two parts, the light rail 101 and the electric tank 102; the cross section of the light rail 101 is in the shape of "I", and the appropriate length is selected according to the site environment for layout, which can be arranged as a square loop or a straight line ; The electric tank 102 is installed in the square hole in the middle of the light rail 101, the middle of the electric tank 102 is a cable, and the direct current of 5A / 24V is used ...

Embodiment 2

[0068] Same as Embodiment 1, the difference is the driving mechanism for driving the jaws of the clamping platform to open and close. The driving mechanism includes a cylinder fixed on the workpiece rotating clamping platform 315, and the cylinder is connected to the bottom plate 324 through its piston rod. connect.

Embodiment 3

[0070] Same as Embodiment 1, how to prevent clamping marks from being left in the process of clamping the workpiece is different. The specific structure is: a plastic backing plate 310 is installed on the surface of the left jaw 301 and the right jaw 323, so that To prevent clamp marks from being left during the clamping of the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com