Six-direction loading rotary experiment table for testing foot type robot

A technology of robots and test benches, applied in manipulators, manufacturing tools, etc., can solve problems such as limited size, limited structure size, and many constraints on leg and foot movement, and achieve the effects of simplifying the experimental process, making the experiment real and reliable, and simplifying the difficulty of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

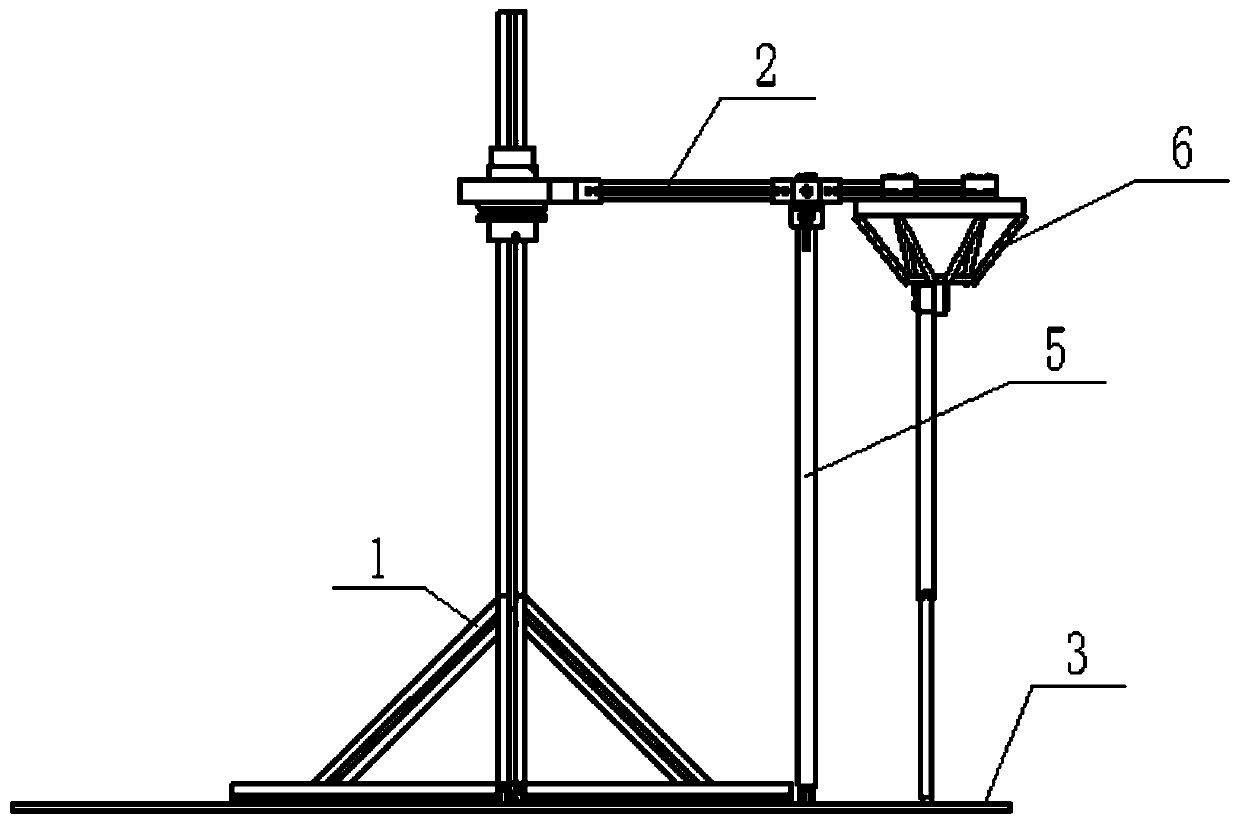

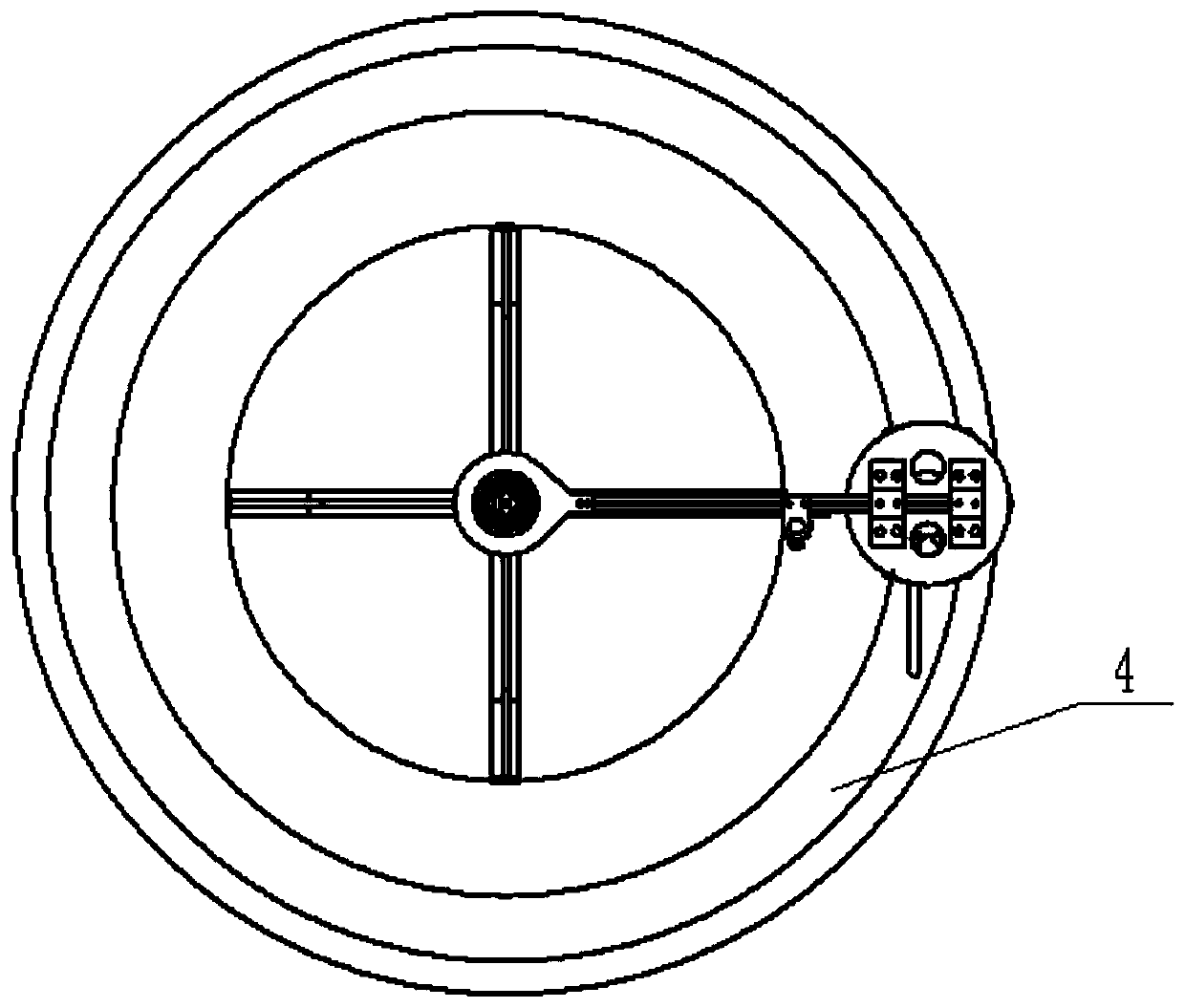

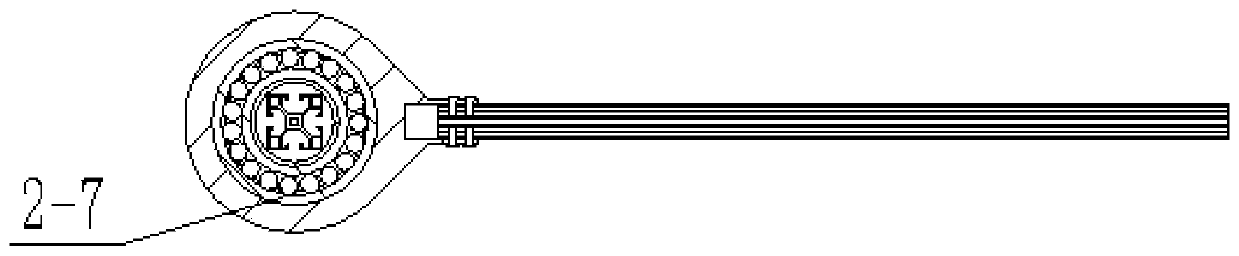

[0021] Such as Figure 1-2 As shown, a six-direction loading rotating test bench for a legged robot includes a longitudinal support 1, a rotating cantilever mechanism 2, a road surface base 3, a force sensing ring 4, a horizontal column support mechanism 5 and a STEWART platform 6, and the road surface The base 3 is located at the bottom, and the pavement base 3 is a ring structure on which ring roads with various parameters can be placed. Its movement distance is infinite, which can realize the test of the fatigue characteristics of the legs and feet of the legged robot, which can greatly simplify the traditional The experimental process and equipment for the fatigue characteristics of legs and feet. The force induction ring 4 is located above the road base 3, the rotating cantilever mechanism 2 is located on the upper part of the longitudinal support 1, the horizontal column support mechanism 5 is located on the side of the middle part of the rotating cantilever mechanism 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com