Integrated full-automatic ointment production line

A fully automatic, integrated technology, applied in liquid materials, mixers, types of packaging items, etc., can solve the problems of inconsistent uniformity of ointment, layered deposition of raw materials, etc., saving labor and time, and less dependence on professional skills. , the effect of reducing pollution and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

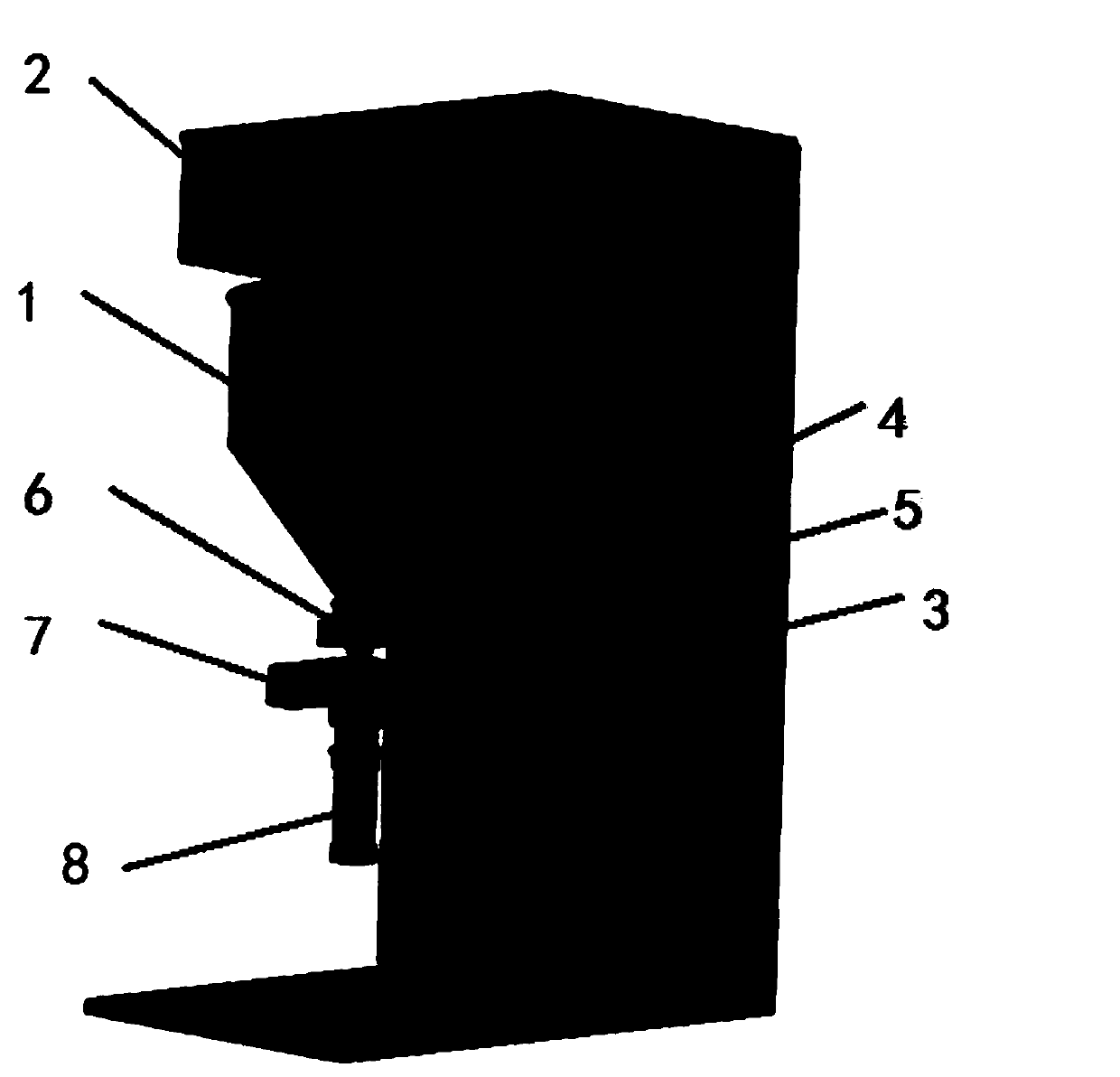

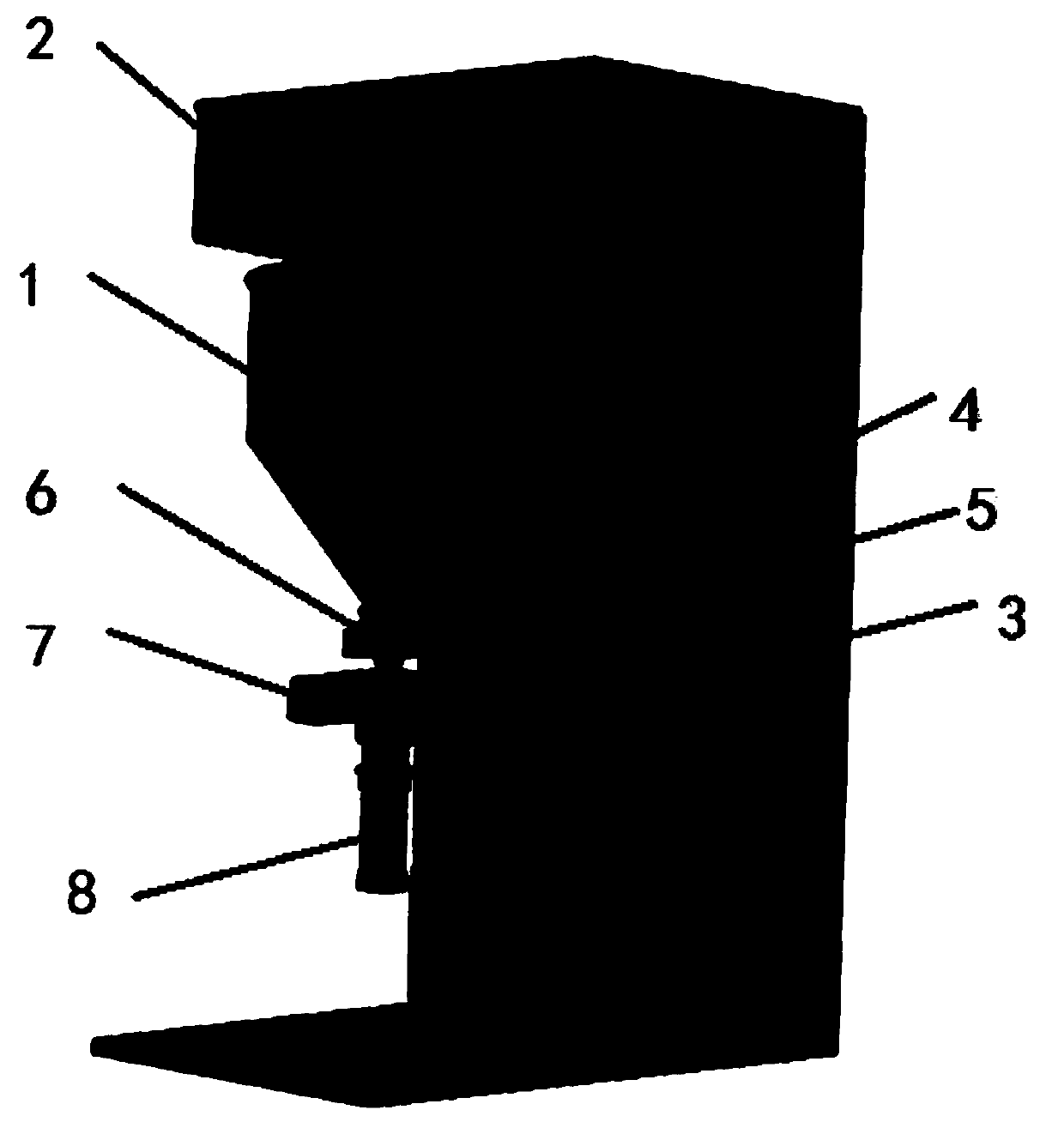

[0026] see figure 1 The integrated automatic ointment production line shown in , includes a mixing tank 1 for mixing raw materials. The stirring rod 2 in the tank is controlled by a frequency conversion motor on the top of the frame. A vertical guide rail 3 is arranged in the frame. On the guide rail An elevating seat 4 is installed, and the mixing bucket is fixed on the elevating seat. The mixing bucket is also provided with a weighing pressure sensor 5 for monitoring its weight. The weighing pressure sensor transmits the monitoring results to the display system, and the display system visually presents the monitoring results on the display screen. Before feeding, the mixing tank needs to descend along the guide rail; when feeding, the weighing pressure sensor monitors the weight of the mixing tank in real time, and the real-time weight is displayed on the display; after feeding, the mixing tank rises to the original position, and the stirring rod starts to stir. The staff c...

Embodiment 2

[0030] The difference between this embodiment and the first embodiment is that the heating component is an integrated heating wire arranged on the wall of the mixing tank, and the integrated heating wire is coated with a waterproof layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com