Steel heat treatment method and system

A heat treatment method and heat treatment system technology, applied in the field of heat treatment of metal processing, can solve the problems such as the limitation of semi-finished steel parts, the limited effect of improving the surface hardness of steel parts, and the inability to significantly improve the area fraction of martensitic structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0116] In order to describe the steel heat treatment method and system proposed by the present invention more clearly, the preferred embodiments of the present invention will be described in detail below with reference to the drawings.

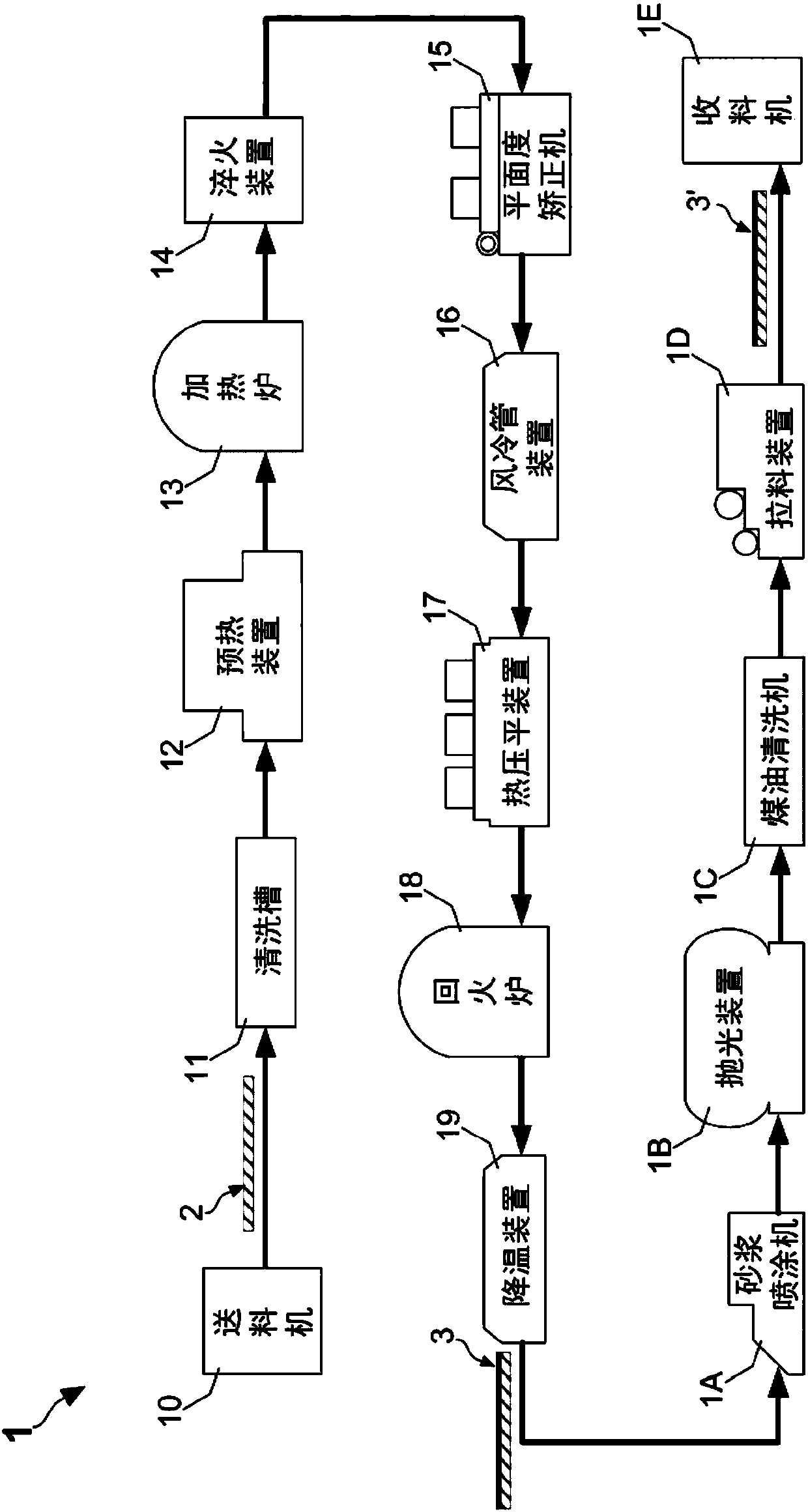

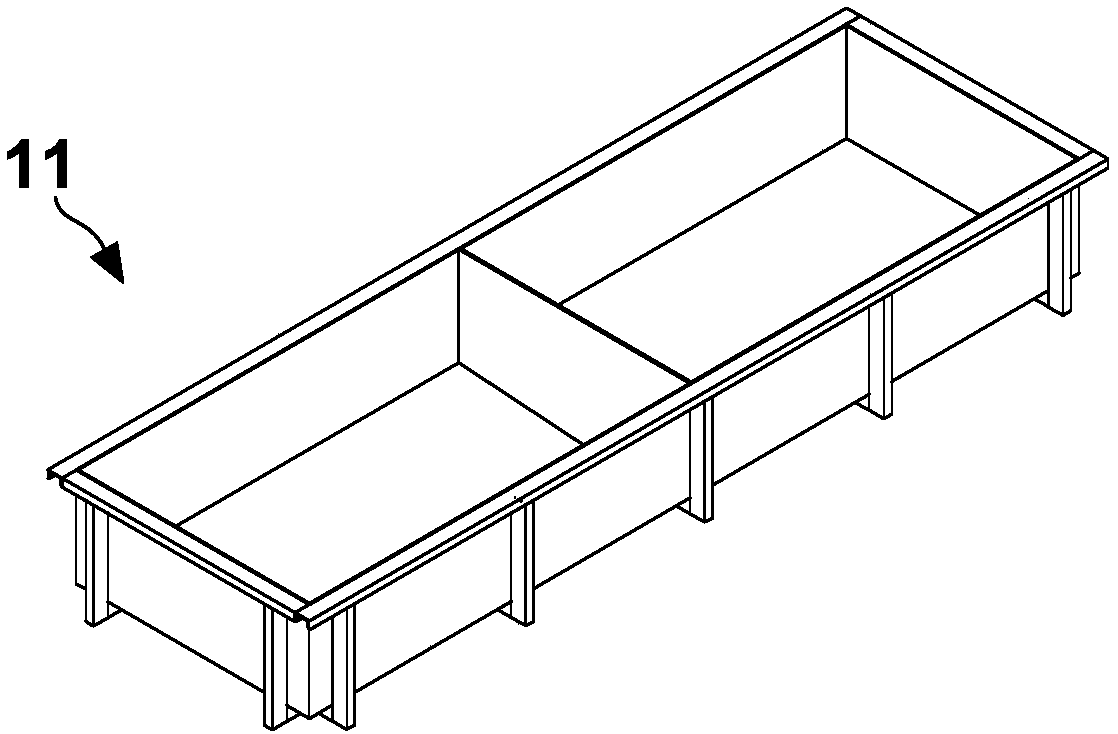

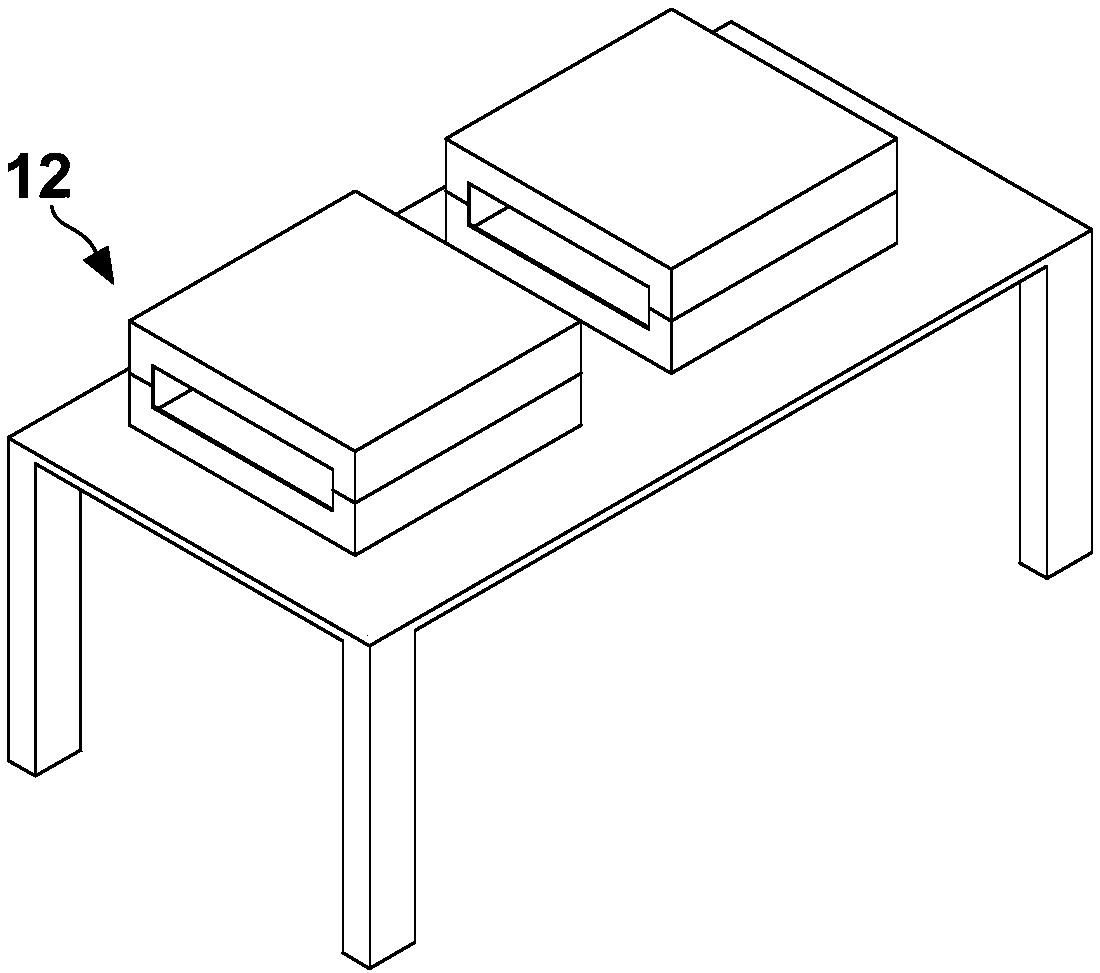

[0117] Before starting to describe the steel heat treatment method of the present invention, it is necessary to introduce a steel heat treatment system for realizing the steel heat treatment method. see figure 1 , is a design drawing showing an automatic production line of a steel heat treatment system of the present invention. Such as figure 1 As shown, the steel heat treatment system 1 is designed according to different process stations of the automated production line, and includes: a feeder 10, a cleaning tank 11, a preheating device 12, a heating furnace 13, a quenching device 14, a Flatness straightening machine 15, an air-cooled pipe device 16, a hot-pressing device 17, a tempering furnace 18, a cooling device 19, a mortar spraying ma...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap