Three-chamber vacuum furnace for high-pressure gas quenching and isothermal salt bath quenching, and use method

A technology of isothermal quenching and gas quenching chamber, applied in the direction of quenching device, furnace, furnace type, etc., can solve the problems that a single furnace type cannot do multiple processes, cannot meet the process requirements at one time, and the workpiece volume is small, and achieves the transportation of workpieces. The effect of short time, fast heating speed and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

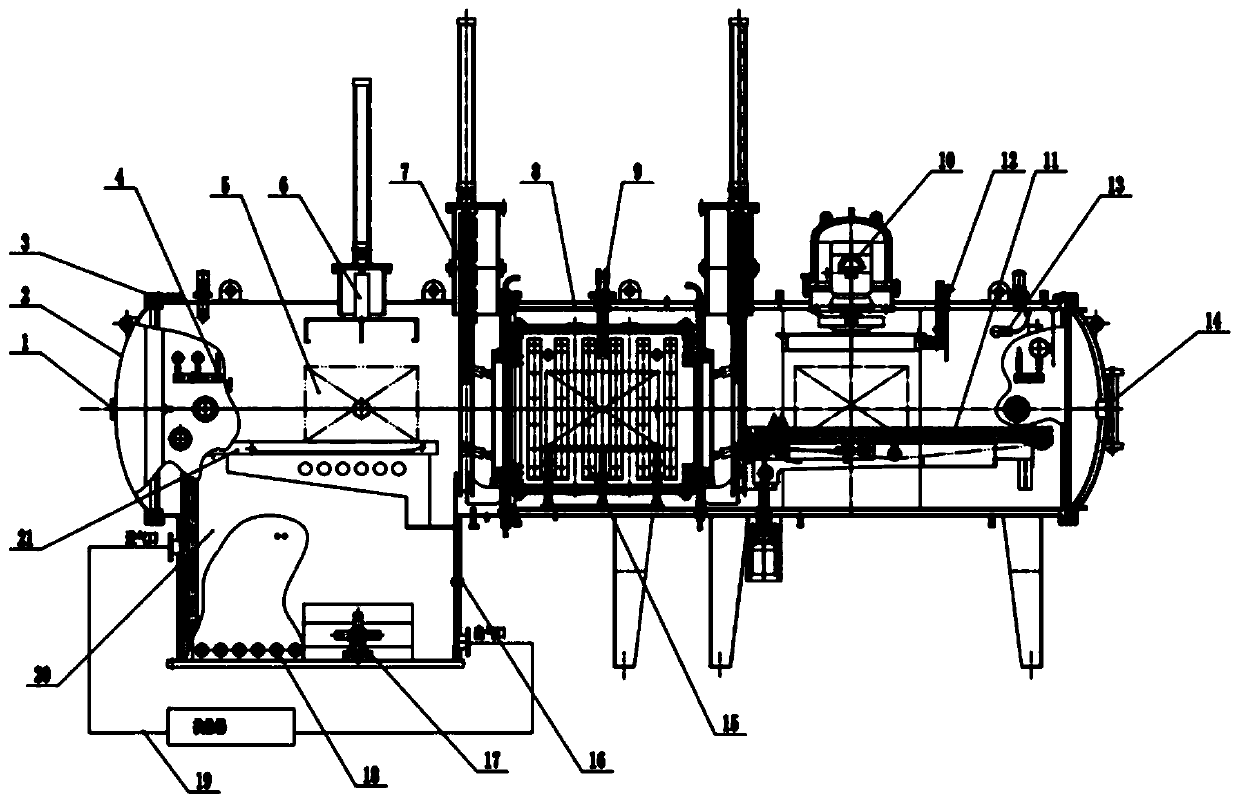

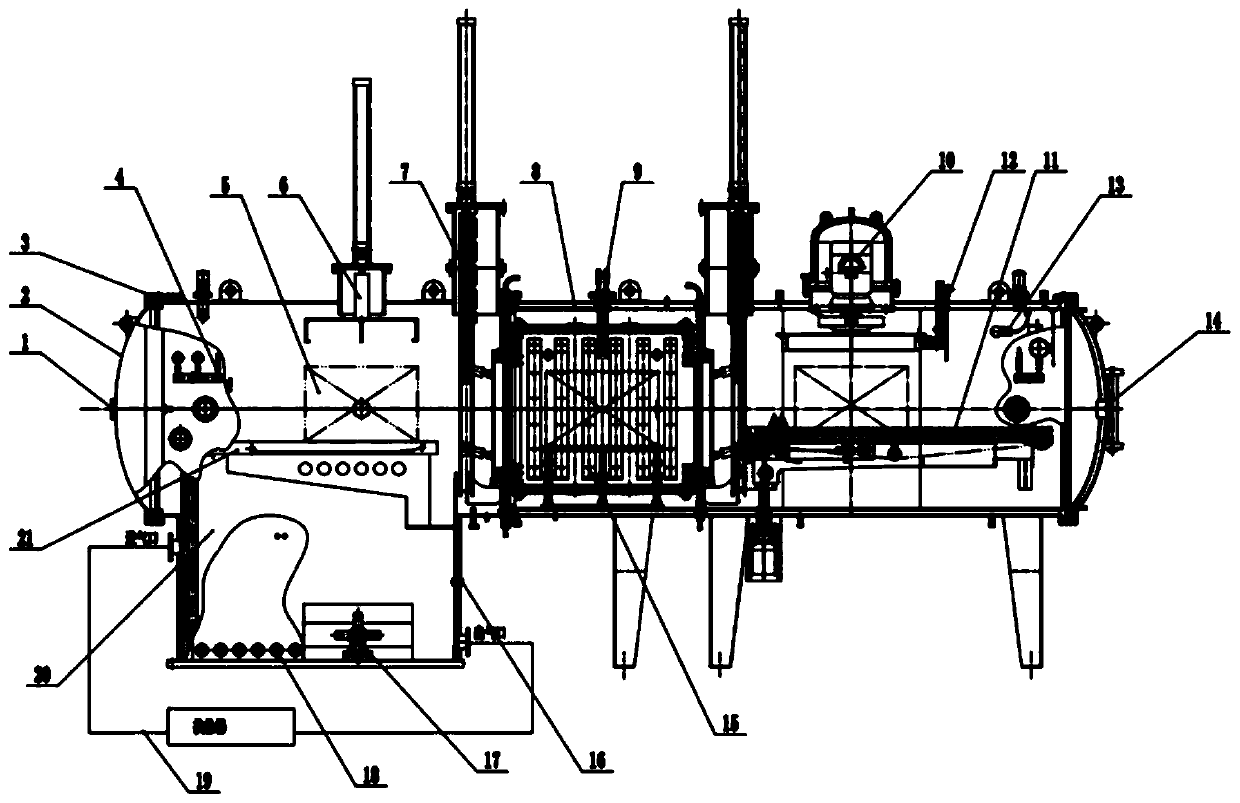

[0022] Such as figure 1 A high-pressure gas quenching salt bath isothermal quenching three-chamber vacuum furnace is shown, including three parts: a gas quenching chamber, a heating chamber and a salt bath; the gas quenching chamber, the heating chamber and the salt bath are connected in sequence;

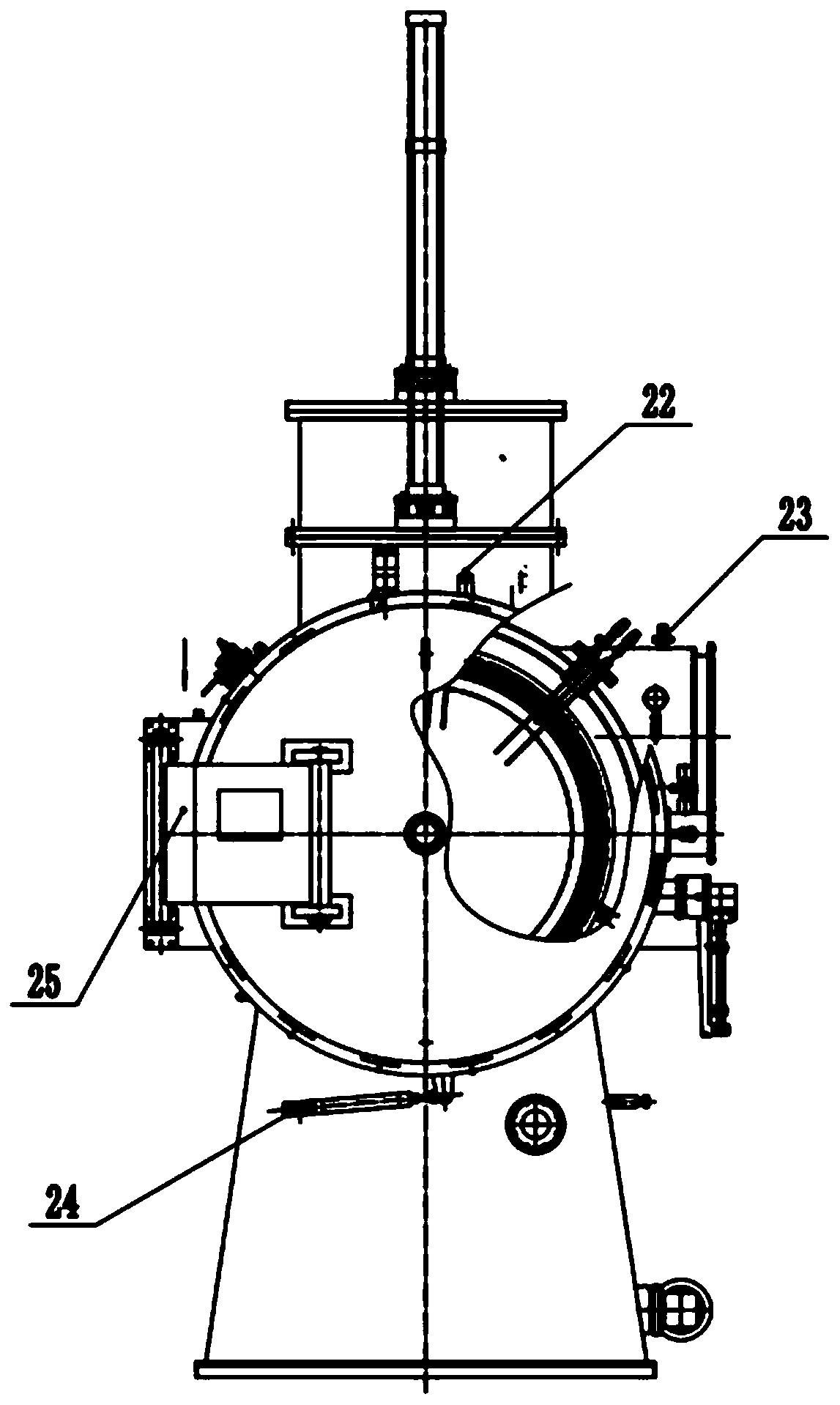

[0023] The gas quenching chamber includes a gas quenching air cooling system 10, a workpiece running structure 11, a gas quenching temperature measuring thermocouple 12, a gas quenching lighting structure 13, a gas quenching observation window 14, a safety valve assembly 22, a vacuum detection gauge 23, and a locking ring Cylinder assembly 24, furnace door B fixing mechanism 25; gas quenching air cooling system 10 and gas quenching temperature measuring thermocouple 12 are installed on the upper end of the gas quenching chamber, and the two cooperate to control the temperature of the gas quenching chamber; gas quenching lighting structure 13 is installed in the gas quenching chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com