Multifunctional polyester fabric and preparation method thereof

A multi-functional, fabric technology, applied in fiber types, textiles and papermaking, fiber processing, etc., can solve problems such as insufficient oleophobicity, complex methods, and lack of effective cross-linking of internal molecules in the coating, achieving excellent antistatic properties, High practical value, highly absorbent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method of multifunctional polyester fabric, concrete steps are:

[0027] (1) will contain photoinitiator 2-hydroxyl-2-methyl-1-phenyl-1-acetone, hydrophilic monomer methacrylic acid, crosslinking agent polyethylene glycol diacrylate, oleophobic monomer 2 -Acetone solution of (perfluorooctyl)ethyl methacrylate, dip-coated on the surface of polyester fabrics. The mass ratio of methacrylic acid to polyethylene glycol diacrylate is 10:1, and the concentration of 2-(perfluorooctyl)ethyl methacrylate is 8 wt%.

[0028] (2) Place the coated polyester fabric in a UV light curing instrument for 25 minutes, and the radiation intensity is 50mW / cm 2 , you can get a multifunctional polyester fabric.

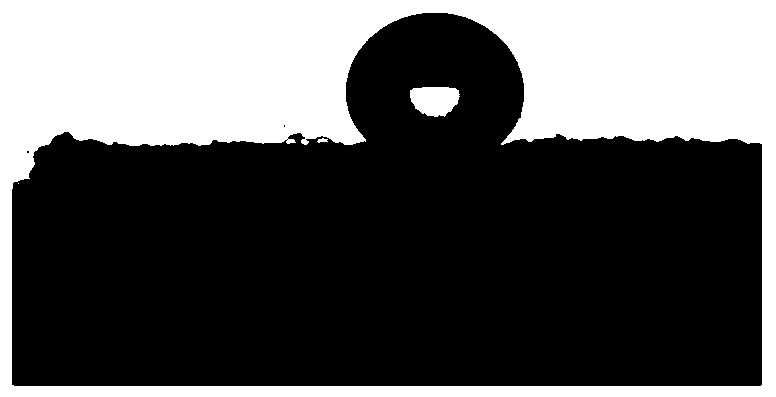

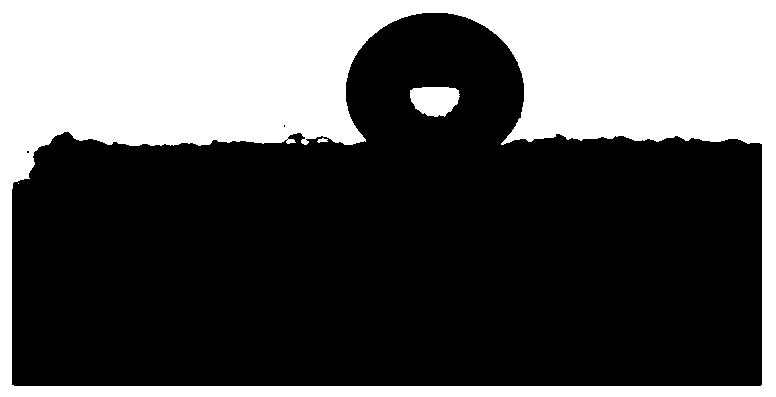

[0029] Utilize the contact angle meter to test the coating prepared above, the result please refer to figure 1 and figure 2 , figure 1 The test result figure of the water contact angle test that utilizes the contact angle meter to carry out the water contact...

Embodiment 2

[0031] A kind of preparation method of multifunctional polyester fabric, concrete steps are:

[0032] (1) will contain photoinitiator 2-hydroxyl-2-methyl-1-phenyl-1-acetone, hydrophilic monomer methacrylic acid, crosslinking agent polyethylene glycol diacrylate, oleophobic monomer 2 -Acetone solution of (perfluorooctyl)ethyl methacrylate, dip-coated on the surface of polyester fabrics. The mass ratio of methacrylic acid to polyethylene glycol diacrylate is 5:5, and the concentration of 2-(perfluorooctyl)ethyl methacrylate is 8 wt%.

[0033] (2) Place the coated polyester fabric in a UV light curing instrument for 25 minutes, and the radiation intensity is 50mW / cm 2 , you can get a multifunctional polyester fabric.

[0034] The above-mentioned treated polyester fabric was tested for contact angle, and the following results were obtained: water droplets spread rapidly on the surface of polyester fabric within 17.3 seconds, and the contact angle of soybean oil was stable at 155...

Embodiment 3

[0036] A kind of preparation method of multifunctional polyester fabric, concrete steps are:

[0037] (1) will contain photoinitiator 2-hydroxyl-2-methyl-1-phenyl-1-acetone, hydrophilic monomer methacrylic acid, crosslinking agent polyethylene glycol diacrylate, oleophobic monomer 2 -Acetone solution of (perfluorooctyl)ethyl methacrylate, dip-coated on the surface of polyester fabrics. The mass ratio of methacrylic acid to polyethylene glycol diacrylate is 1:10, and the concentration of 2-(perfluorooctyl)ethyl methacrylate is 8 wt%.

[0038] (2) Place the coated polyester fabric in a UV light curing instrument for 25 minutes, and the radiation intensity is 50mW / cm 2 , you can get a multifunctional polyester fabric.

[0039] The above-mentioned treated polyester fabric was tested for contact angle, and the following results were obtained: water droplets spread rapidly on the surface of polyester fabric within 17.7 seconds, and the contact angle of soybean oil was stable at 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com