Inclined column formwork support system and construction method thereof

A formwork support and construction method technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of labor and time consumption in construction, and achieve the effect of ensuring bearing capacity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

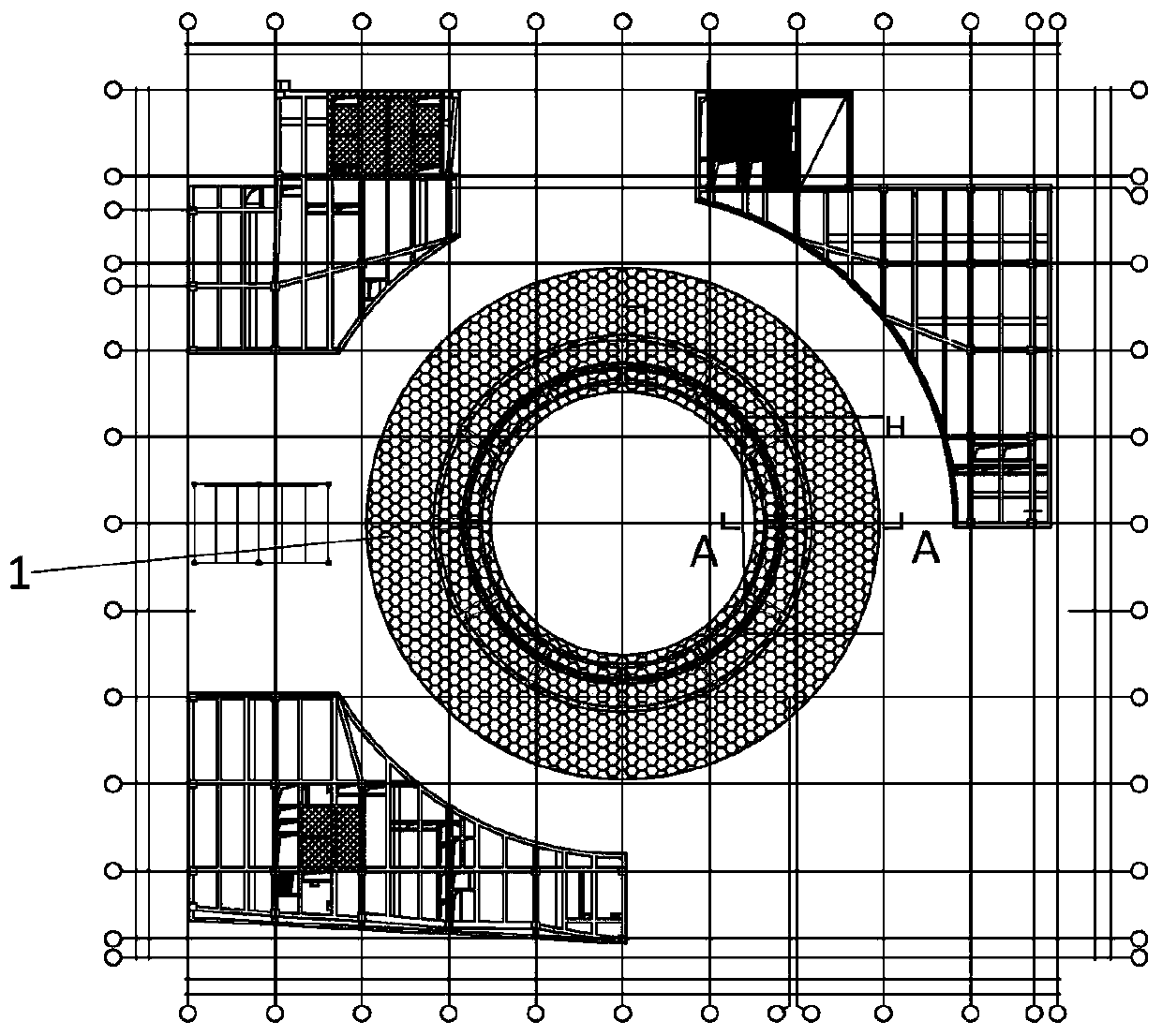

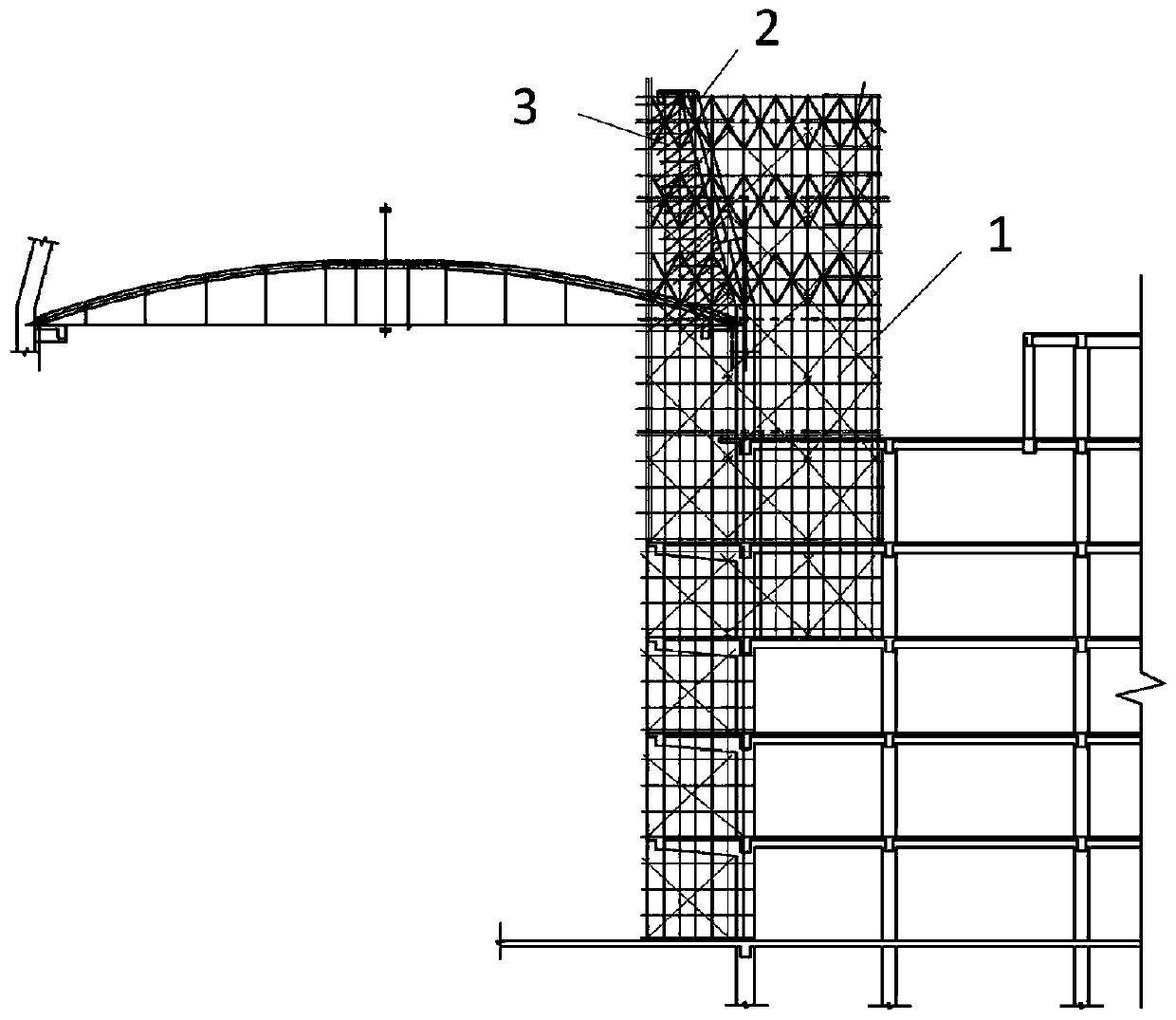

[0030] Such as Figure 1 to Figure 8 As shown, the present invention provides a slanted column formwork support system, comprising: a floor support frame 1 and a slanted column formwork 2 installed on the floor support frame 1 .

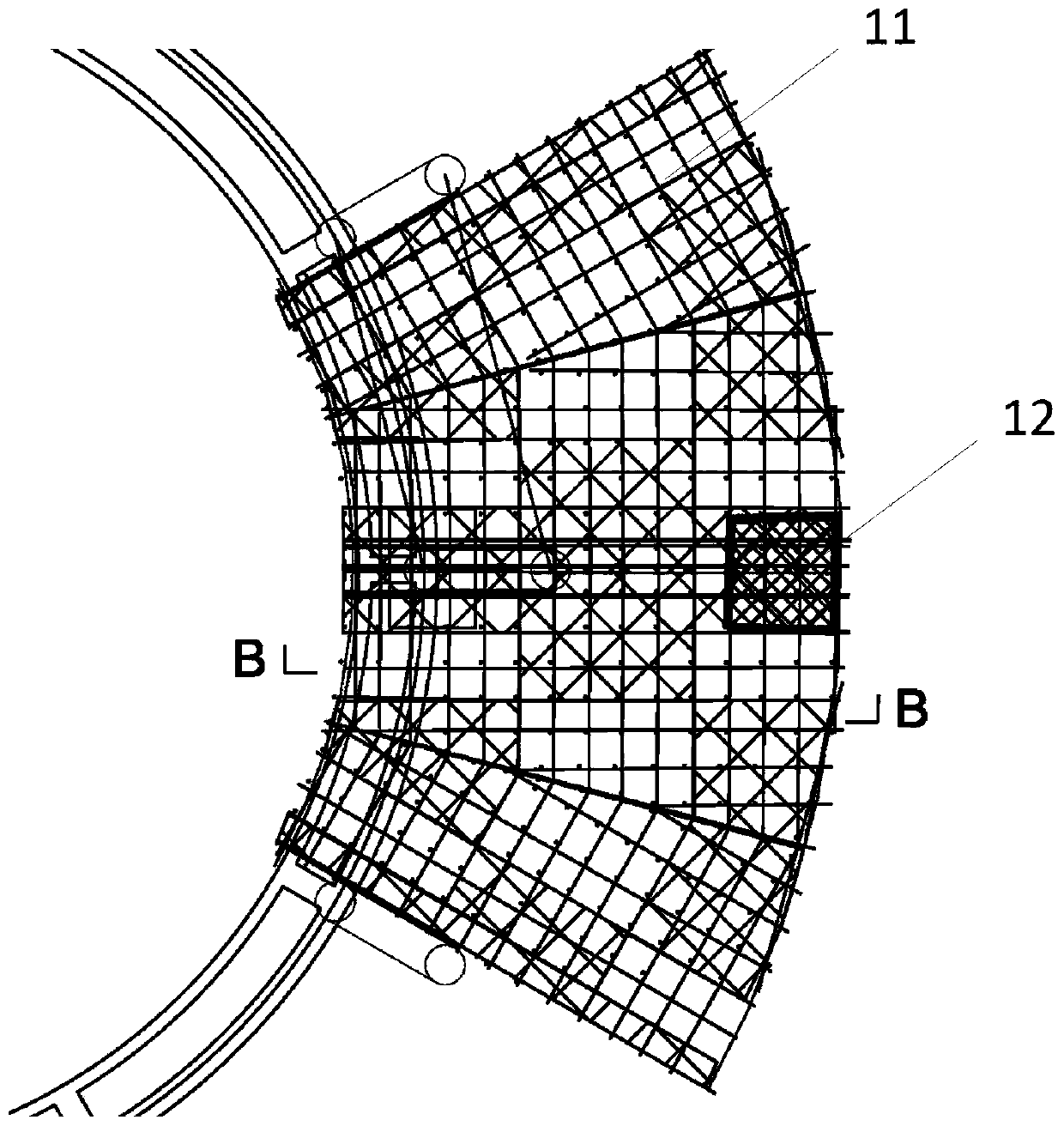

[0031] key reference Figure 1 to Figure 4 The floor support frame 1 includes: a full hall formwork support 11 and a counterweight ballast 12, wherein the full hall formwork support 11 that is located on both sides of the inclined column formwork 2 and needs to be poured in b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com