Ultrasonic thickness gauge for metal composite material

A metal composite material, ultrasonic technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, analyzing materials, using sonic/ultrasonic/infrasonic waves to analyze solids, etc. problem, to achieve the effect of preventing smearing, improving sensitivity, and reducing switching noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

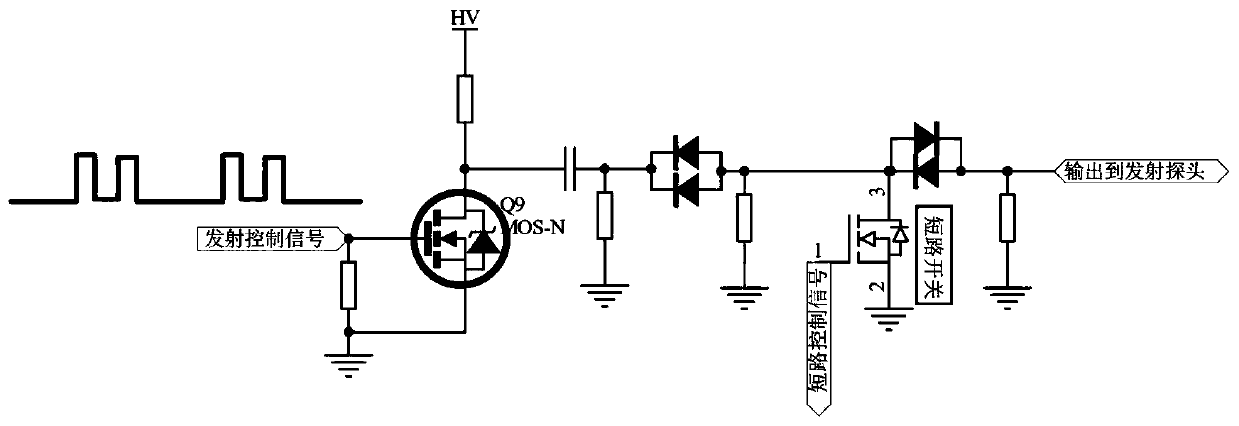

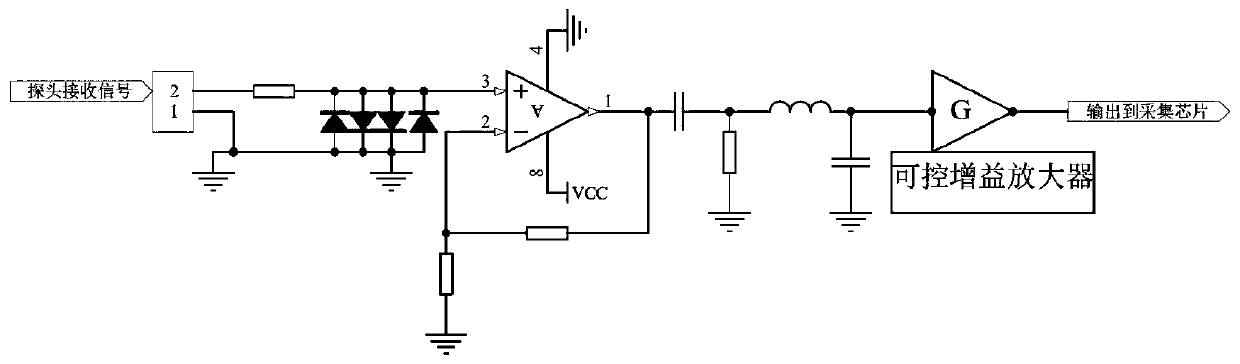

[0045] Such as Figures 1 to 10 As shown, a metal composite material ultrasonic thickness gauge includes an adjustable voltage power supply, an ultrasonic transmitting module, an ultrasonic receiving module, a data acquisition module, a data processing system and a housing. The power supply provides power for the ultrasonic transmitting module, the ultrasonic receiving module, the data acquisition module and the data processing system. The ultrasonic transmitting module transmits the high-voltage pulse signal with noise reduction and isolation processing, and releases the redundant pulse signal after transmitting the pulse signal; the ultrasonic receiving module receives the bottom reflection wave of the metal composite material and the interlayer interface reflection wave (for For the convenience of the description, the bottom surface radiation wave and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com