Feeding mechanism for cotton straw harvesting and harvester comprising feeding mechanism

A technology of feeding mechanism and cotton stalks, which is applied in the field of harvesters, can solve the problems of inapplicability, less research, high branch hardness and toughness, etc., and achieve the effect of increasing the working range, avoiding blockage, and reliable delivery

Pending Publication Date: 2019-07-16

SHANDONG ACADEMY OF AGRI MACHINERY SCI

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Cotton straw has many branches, high hardness and toughness, and the shape and properties of the straw are very different from those of wheat and corn, which increases the difficulty of transportation. Therefore, the straw feeding mechanism used for wheat and corn is obviously not suitable for cotton straw transportation. There are few studies on the special feeding mechanism for cotton stalks

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

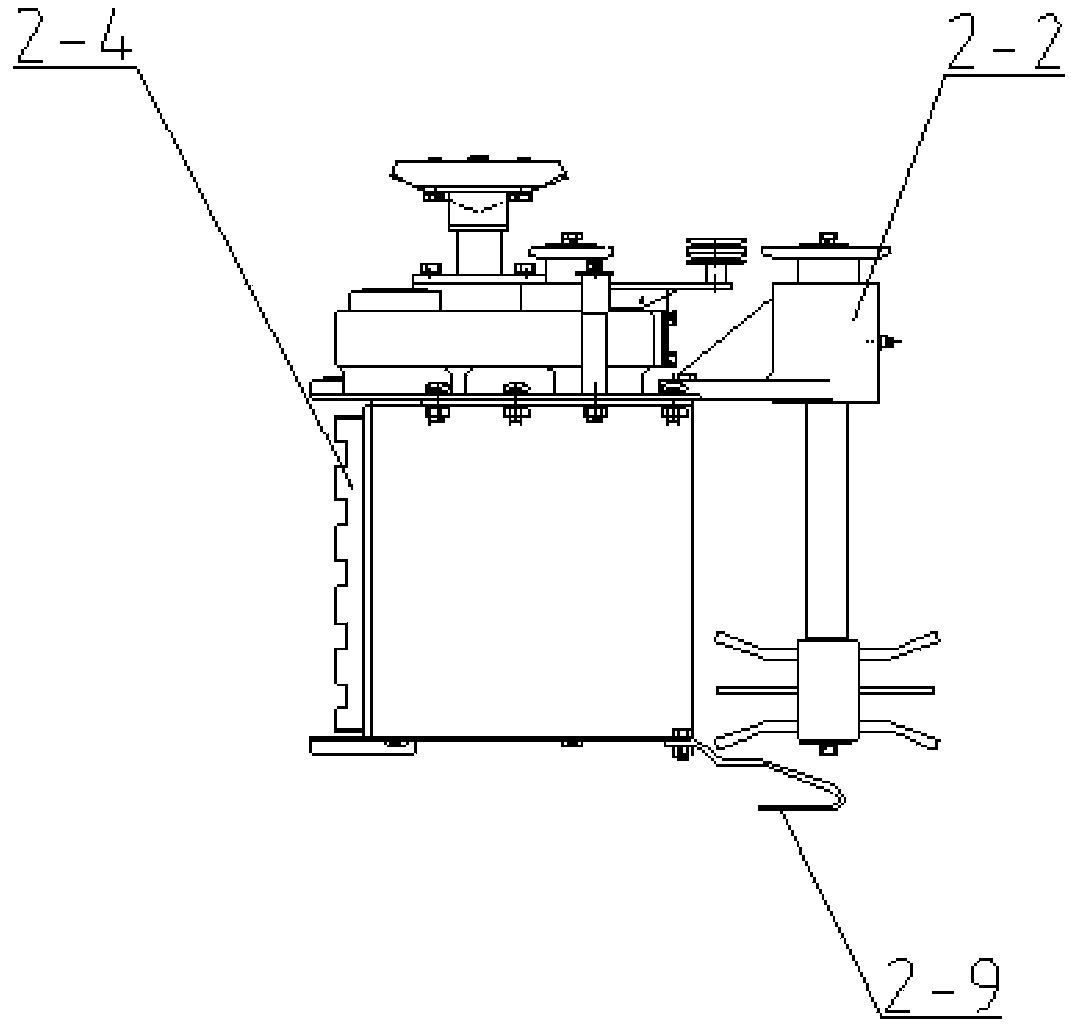

[0066] This embodiment also discloses a harvester including the feeding mechanism described in Embodiment 1. The feeding mechanism is the middle link of the cotton stalk harvester. The conveying function of linking up and down connects the normal work of the front and back links, and is a very important link in the mechanized harvesting of cotton stalks.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

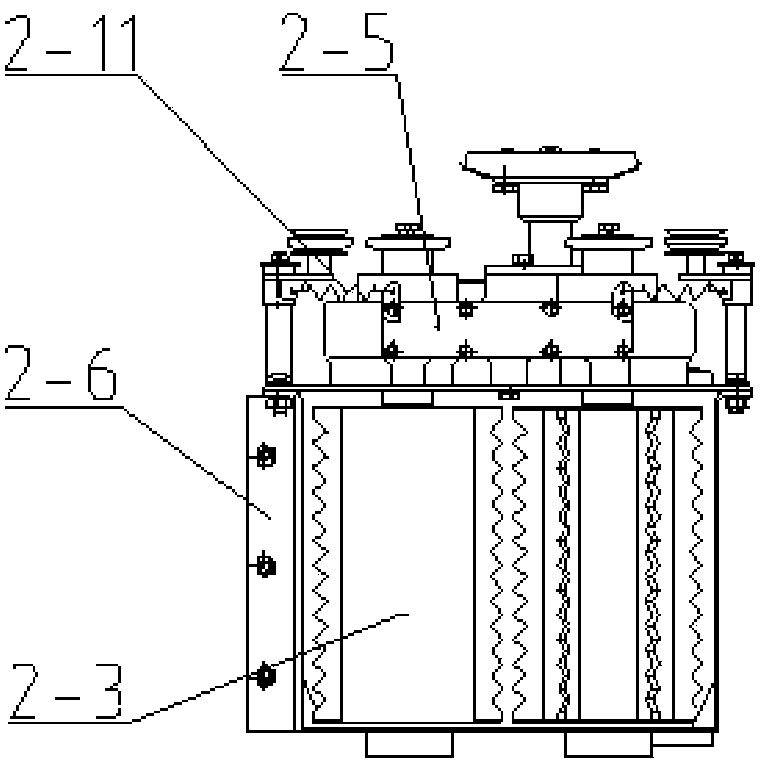

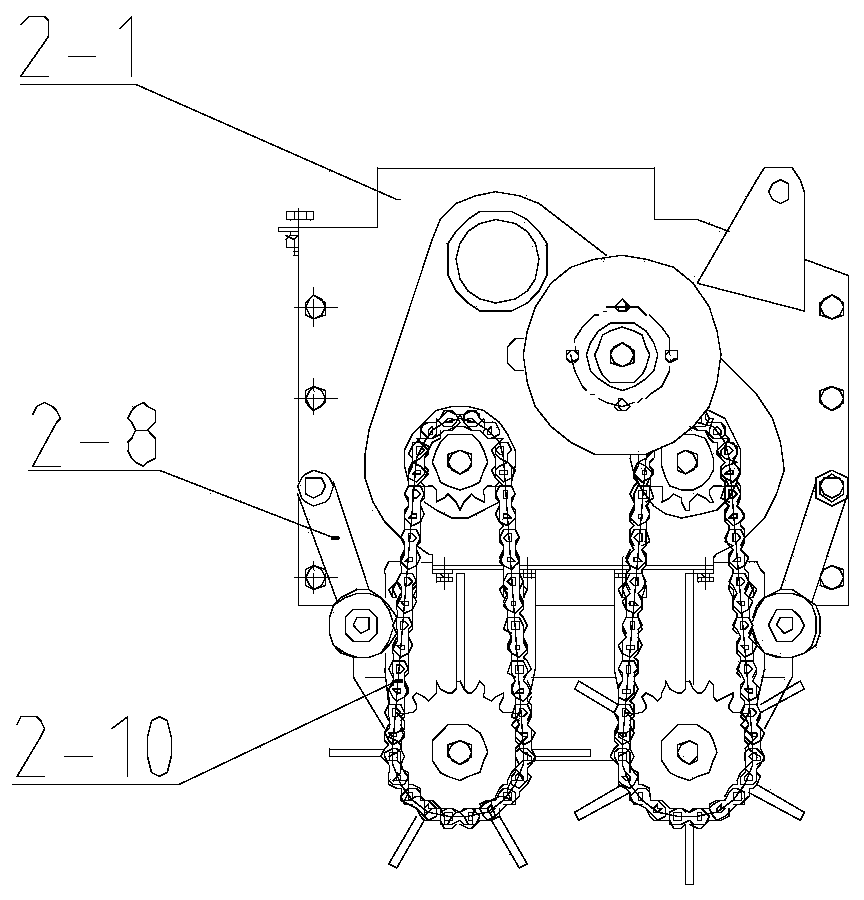

The invention discloses a feeding mechanism for cotton straw harvesting and a harvester comprising the feeding mechanism. The feeding mechanism comprises a frame, two auxiliary feeding rollers, two front feeding rollers and a rear feeding roller are mounted on the frame, and the auxiliary feeding rollers, the front feeding rollers and the rear feeding roller are parallel one another in axis; eachauxiliary feeding roller includes a dial shaft, one end of the dial shaft is connected with a transmission device while the other end is provided with three layers of dials thereon, each dial is provided with multiple pulling teeth, and the pulling teeth located on the dials of the upper and lower layers are bent pulling teeth opposite in bending direction; the pulling teeth of the dial located inthe intermediate layer is straight pulling teeth; the front feeding rollers are located in the rear of the auxiliary feeding rollers and in back and front correspondence to the auxiliary feeding rollers, and the corresponding front feeding rollers and auxiliary feeding rollers rotate are driven by a transmission chain to rotate in the opposite direction; the rear feeding roller is located in therear of the front feeding rollers and rotates anticlockwise.

Description

technical field [0001] The invention discloses a feeding mechanism for mechanized harvesting of cotton stalks and a harvester comprising the mechanism. Background technique [0002] Cotton stalk is an important straw resource with a wide range of uses. Harvesting cotton stalks is the advance of comprehensive utilization of cotton stalks, and mechanized harvesting is the fundamental way to solve the problem of labor-intensive and low-efficiency cotton stalk harvesting. The transportation of cotton stalks is one of the difficulties restricting the mechanized harvesting of cotton stalks. The characteristics of cotton stalks with many branches and hard wood make the transportation difficult and the transportation effect is poor. [0003] The existing cotton stalk feeding mechanisms are basically modified by wheat and corn stalk feeding mechanisms. When the cotton stalk harvester using these feeding mechanisms works, the straw feeding mechanism is prone to the phenomenon that th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A01D57/01A01D57/22A01D43/08A01D46/08

CPCA01D43/08A01D43/086A01D46/08A01D57/01A01D57/22

Inventor 王小瑜荐世春康建明彭强吉

Owner SHANDONG ACADEMY OF AGRI MACHINERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com