Multifunctional baking equipment

A kind of baking equipment and multi-functional technology, which is applied in the direction of roaster/barbecue grid, cooking utensils, kitchen utensils, etc., can solve the problems of low heating speed, long heating time, and loud gear mechanical rotation noise, and achieve uniform heating, Fast heating, no preheating required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment describes a multi-functional baking equipment, which can provide 360° all-round heating, and can also choose one or more sides to radiate heat according to needs, fully meeting the baking requirements under different conditions, and the heating used The thermoelectric conversion efficiency of the element is high, the temperature rises rapidly, and no preheating is required, which improves the heating speed while ensuring that the food is heated evenly.

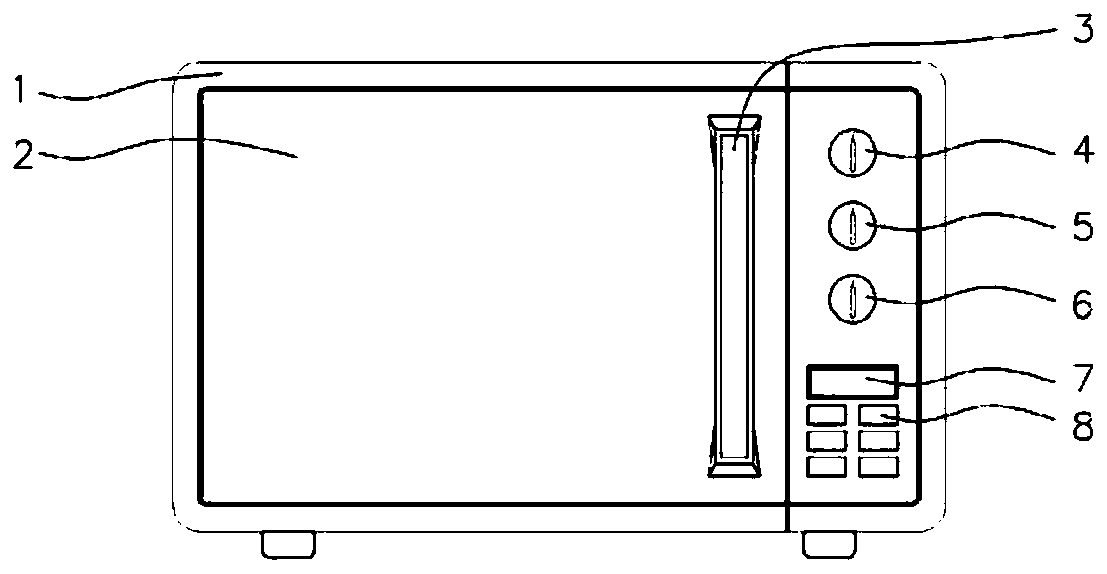

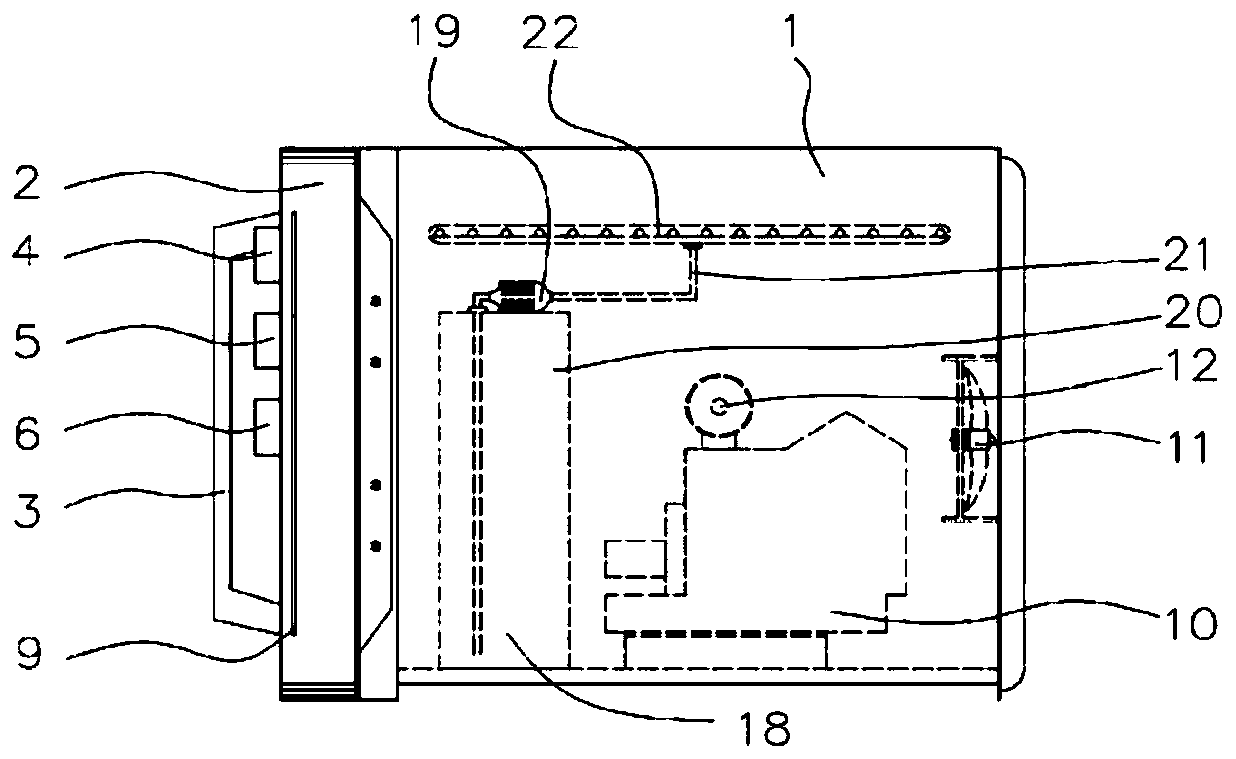

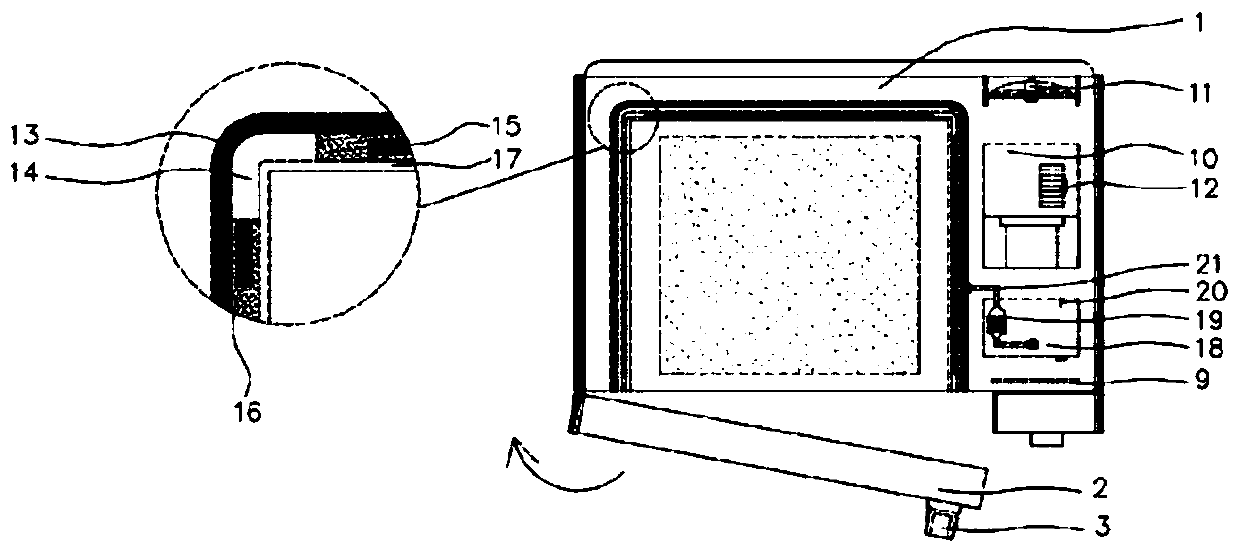

[0033] The baking equipment is composed of a box body 1 and a door body 2 like a traditional oven, such as figure 1 As shown, the box body 1 is provided with an opening, and the door body 2 is installed at the opening and matches with the opening. A door panel handle 3 is installed on the door body 2 in addition to facilitate opening and closing of the door body 2. A protective layer can be established on the outer surface of the door panel handle 3 to avoid scalding the operator or damaging the door pan...

Embodiment 2

[0048] The baking equipment of the present embodiment is similar to embodiment 1, as figure 1 As shown, the box body 1 is provided with an opening, and the door body 2 is installed at the opening and matches with the opening. A door panel handle 3 is installed on the door body 2 in addition to facilitate opening and closing of the door body 2. A protective layer can be established on the outer surface of the door panel handle 3 to avoid scalding the operator or damaging the door panel handle 3 surface. In this embodiment, the baking equipment can be provided with a transparent and heat-insulated glass observation area on any one or several sides of the box body 1 or the door body 2, so as to facilitate observation of the state of cooking food.

[0049] Cabinet 1 is equipped with an intelligent temperature control system, which includes temperature knob 4, function selection knob 5, time knob 6, LED display 7, menu function buttons 8, control panel 9 and buzzer 12, such as fig...

Embodiment 3

[0088] In a preferred embodiment, the baking equipment is also provided with a steam device, so that it has a steam function, and the steam mode can be selected through the function selection knob 5 .

[0089] Such as figure 2 and image 3 As shown, there is a water box groove on one side of the baking equipment of this embodiment, which is used to place the matching water box 18. The water box 18 is detachable and is provided with a handle for easy access. The water port can be opened at any time, and the operation of adding water can be performed at any stage of the equipment operation at any time. The water box 18 is equipped with a water pump 19 and a water level sensor 20, and the water pump 19 and the water level sensor 20 are connected to the control panel 9 respectively. The water pump 19 is used to output the water in the water box 18, and the amount of water delivery is controlled by the control panel 9, and then the steam rate can be adjusted. The water level se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com