Secondary pile splicing construction method and terrace structure thereof

A construction method and floor technology, applied in the field of pile foundation structure, can solve the problems of affecting the construction progress, increasing the amount of backfill and excavation, and the instability of the pile driver, so as to avoid the influence of bad weather, improve the connection strength, and improve the efficiency. fencing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

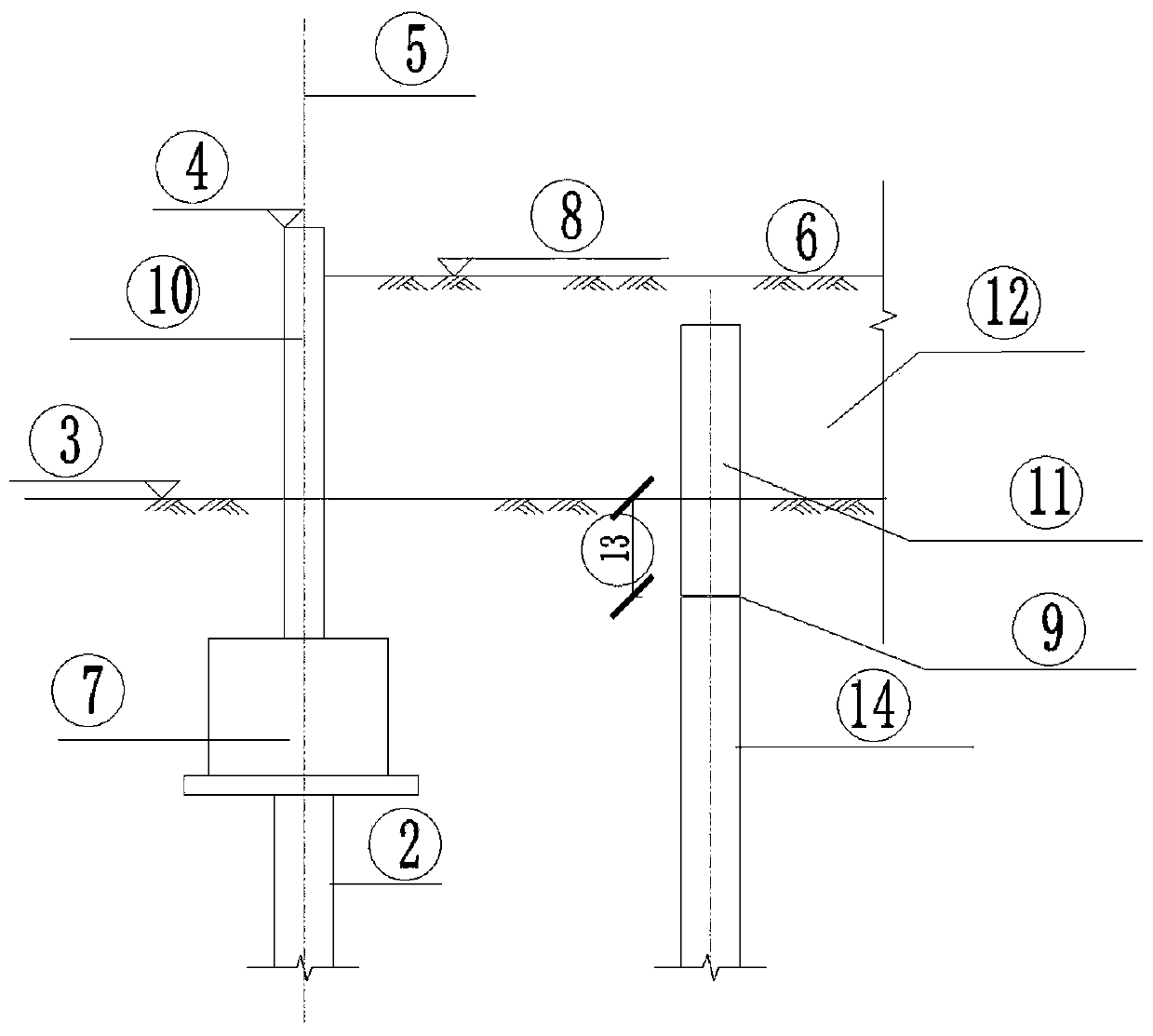

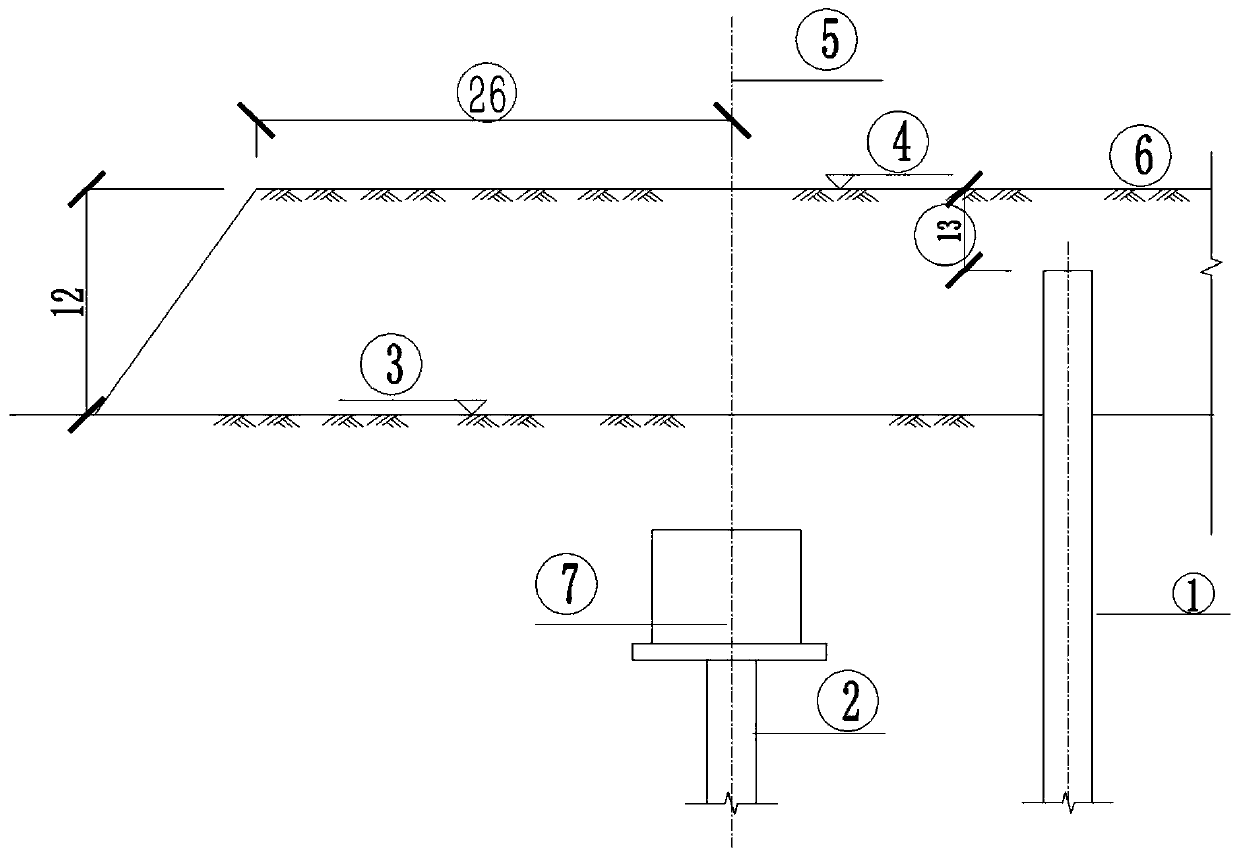

[0042] Such as figure 1 As shown, the floor structure of the present invention's secondary pile connection construction method includes floor piles 1 and cap piles 2; right part), the ground pile 1 includes a first section pile 14 and a second section pile 11, the first section pile 14 is constructed by a pile machine, and the second section adopts mechanical cooperation to manually carry out short pile welding, so as to avoid the one-time operation of the whole section Construction, the construction period of using the pile driver is shorter, and the hidden dangers caused to it in rainy days will be correspondingly reduced. The top of the first section of pile 14 is located below the natural ground, and the upper end of the first section of pile 14 is connected to the first section of pile 14. The lower end of the second section pile 11 is welded; the cap pile 2 is distributed on the building side axis 5, the cap pile 2 is located below the natural ground, and the top of the...

Embodiment 2

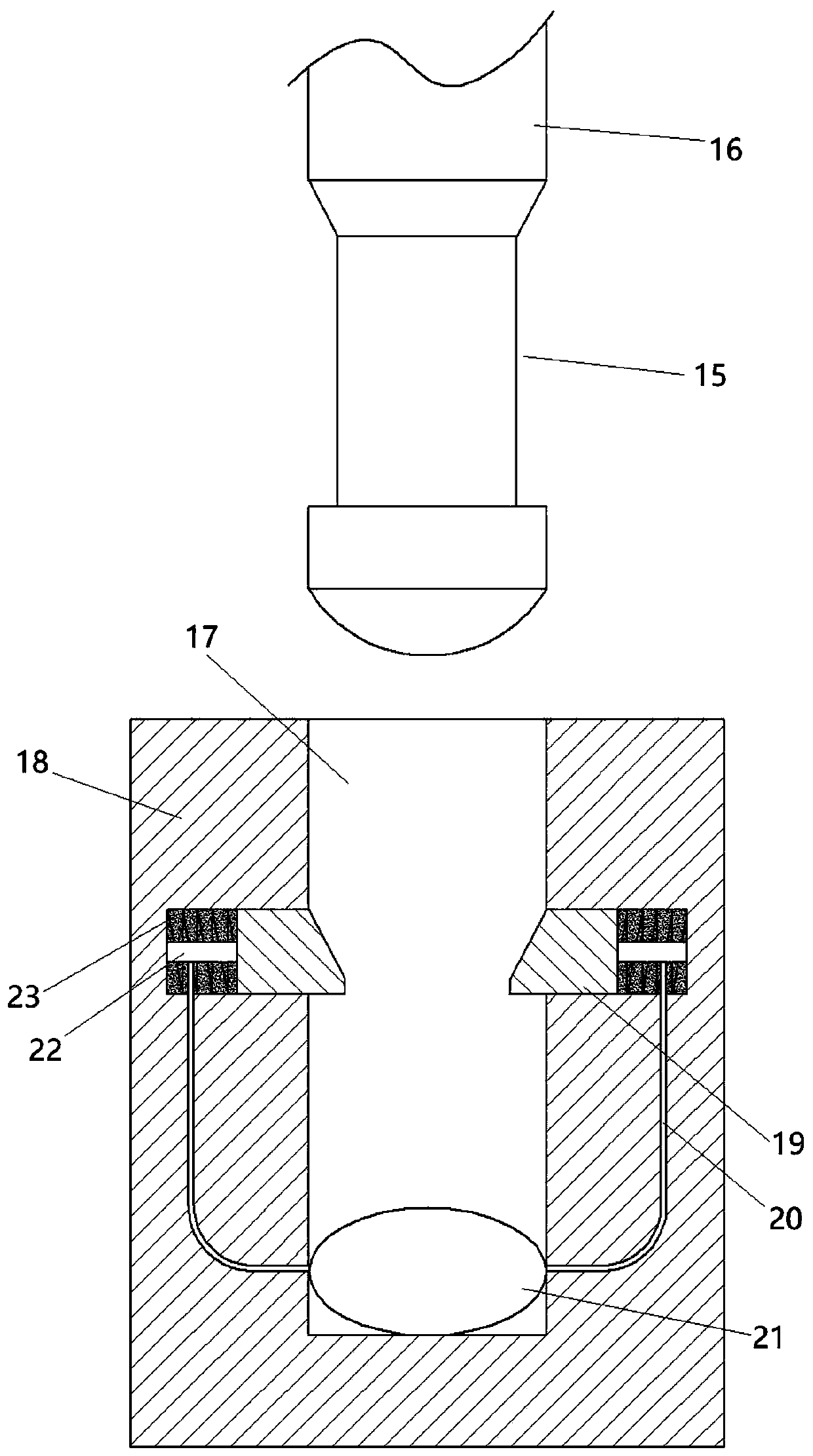

[0054] Compared with the floor structure of embodiment 1, such as image 3 As shown, this embodiment also includes a connecting component and a locking component, and the connecting component and the locking component are matched and welded to connect the first segment pile 14 and the second segment pile 11 .

[0055] The connecting assembly includes a connecting column 16 and a connecting seat 18, the upper end of the connecting column 16 is connected to the lower end surface of the second section pile 11, the lower end of the connecting column 16 is an arc surface structure, and the arc The upper outer circumference of the surface structure is provided with a necking section 15; the connecting seat 18 is fixed on the upper end surface of the first section pile 14, and the upper end surface of the connecting seat 18 is provided with a keyhole, and the side of the keyhole The wall is provided with a pin hole 17, and a lock pin 19 and a spring are matched in the pin hole 17, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com