A method of controlling grease contaminants

An oil composition and oil technology, applied in the field of oil, can solve the problems of loss, excessive glycidol content of functional oil, unsatisfactory effect, etc., and achieve the effect of reducing potential harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The invention also provides a preparation method of the food. The method comprises contacting the raw material of the food with the aforementioned oil and fat composition, or contacting the raw material of the food with the base oil and the aforementioned composition, or bringing the raw material of the food into contact with the base oil, trehalose and Phospholipid contact.

[0049] In the present invention, food includes edible products prepared using edible oil, processed at high temperature, and non-limiting examples thereof include: French fries, chicken wings, fried dough sticks, and tempura. The high-temperature treatment includes, but is not limited to, at 180-210° C., the following treatments are performed: frying, stir-frying, roasting, and deep-frying.

[0050] The present invention also provides the use of trehalose and phospholipids for reducing and / or controlling 3-MCPD ester and / or GE in frying oil.

[0051] The present invention also provides trehalose...

Embodiment 1

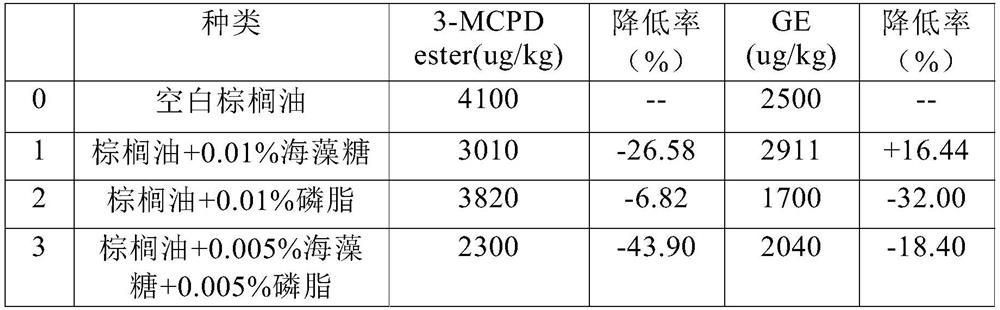

[0070] As shown in Table 1, add trehalose and / or phospholipid to palm oil, after mixing evenly, place it in a high-temperature dry bath at 210°C for 24h, and place the palm oil without trehalose and phospholipid at 210°C Under the high temperature condition of ℃, heating for 24h was used as a control. Detect the content of 3-MCPD ester and GE and calculate the reduction rate of 3-MCPD ester and GE in different schemes relative to blank palm oil. The results are shown in Table 1.

[0071] Table 1

[0072]

[0073]

Embodiment 2

[0075] The trehalose and phospholipids were added to 2.5 kg of palm oil according to the addition amount in Table 2, and they were uniformly dissolved. Then, the oil is placed in a constant temperature frying pan, heated to 180° C., and after the temperature is constant, French fries are added to the frying pan for frying. Continue to heat for 7 hours a day, fry 200g of French fries each time, fry 3 minutes, fry 15 times in the morning, 15 times in the afternoon, and empty the rest of the time. For 5 days, a total of 300 times of frying were performed. After the last frying, a 100 g oil sample was taken to detect the content of 3-MCPD ester and GE. The results are shown in Table 2.

[0076] Table 2

[0077]

[0078]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com