Automatic soda ash solution perfusing system and soda ash solution perfusing method thereof for steamed sponge cakes

A technology for automatic grouting and cake making, which is applied in the fields of food forming, food science, application, etc., can solve problems such as affecting the delivery rate of qualified products, affecting the quality of cakes, and defects in the production quality of cakes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

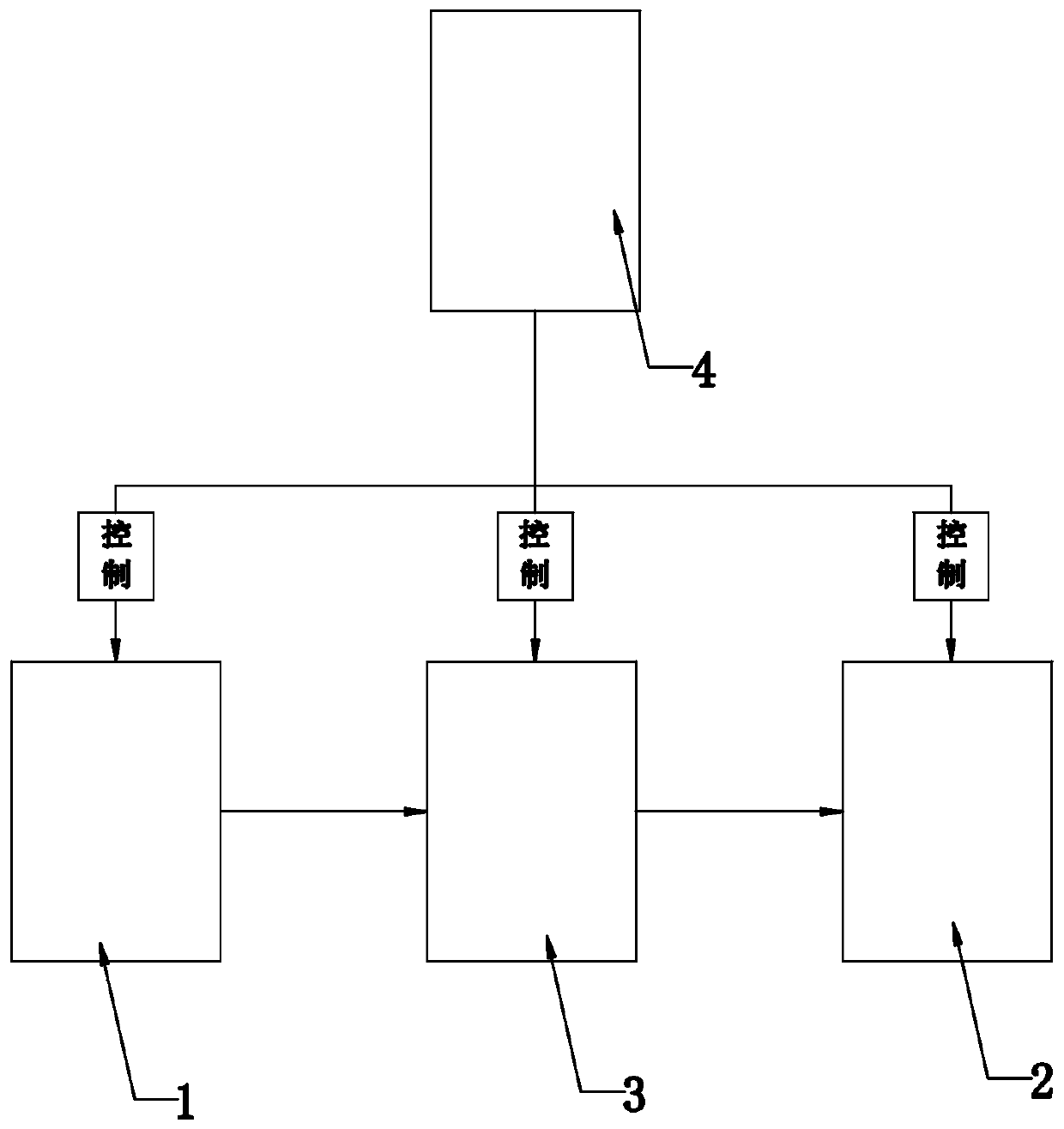

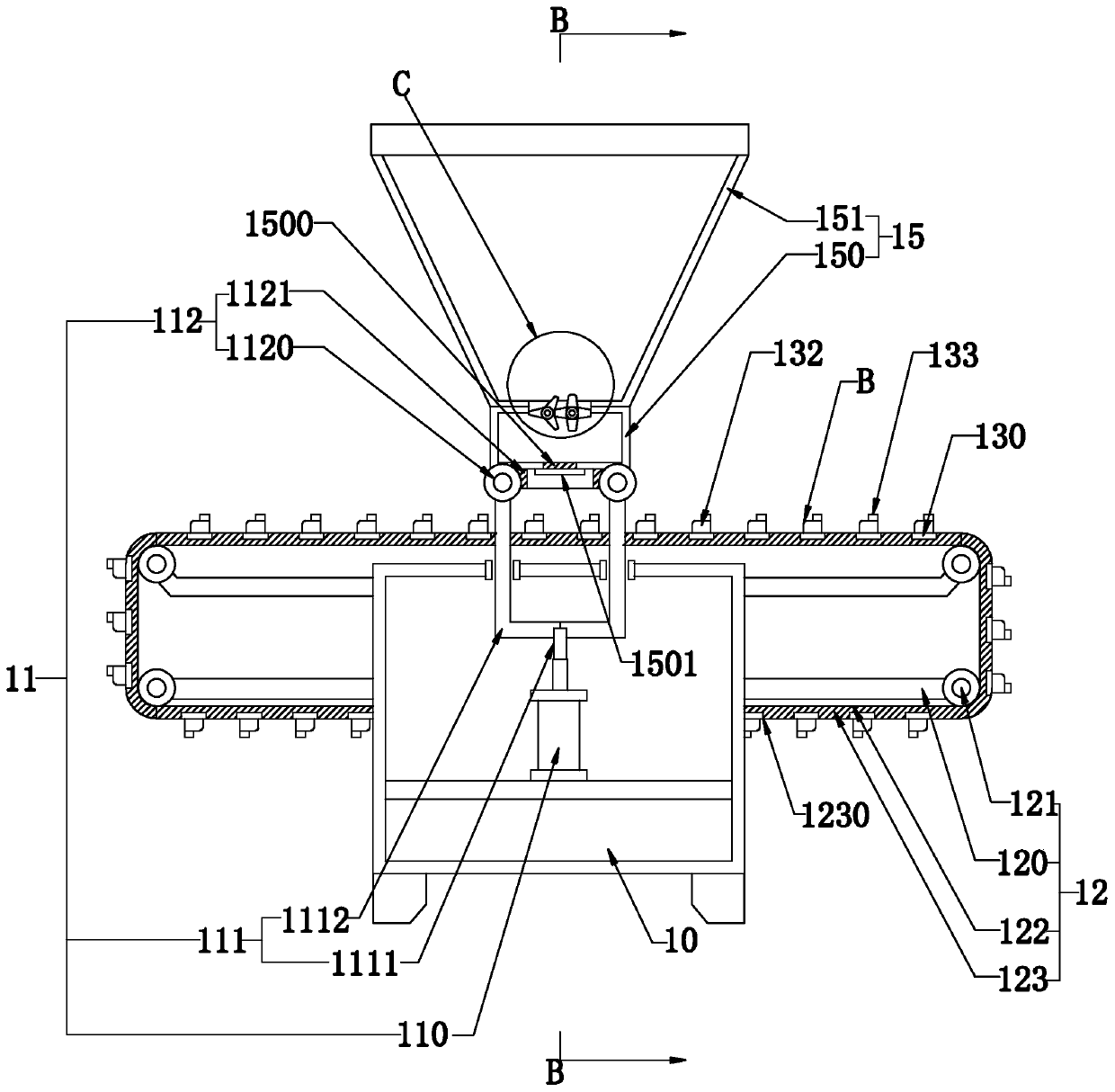

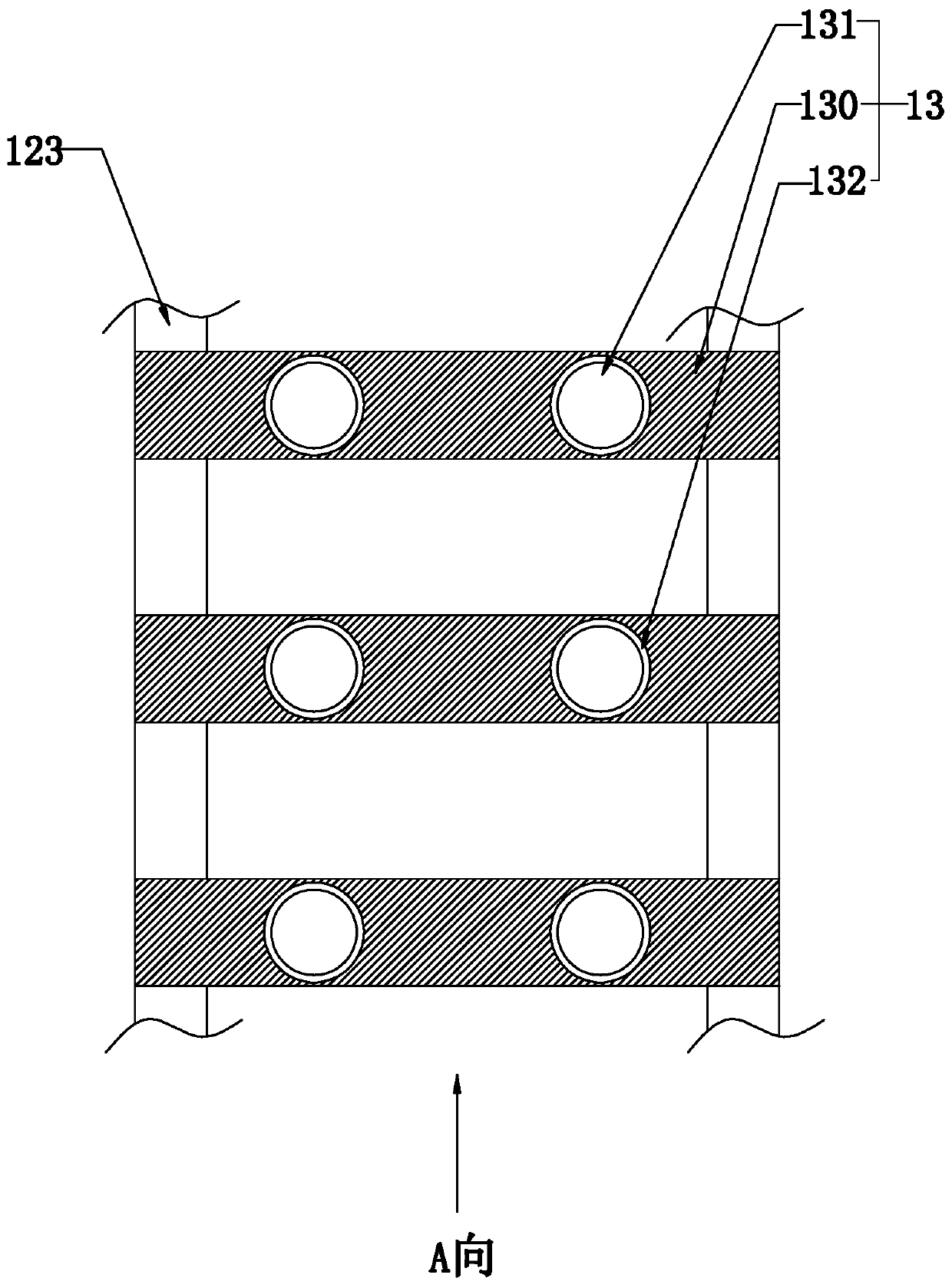

[0045] Such as Figure 1 to Figure 16 As shown, the present invention discloses an automatic grouting system for steamed cakes, see figure 1 , in a specific embodiment of the present invention, comprising a grouting device 1, an auxiliary device 2 for assisting the grouting device 1 in producing cakes, a transfer device 3 disposed between the two, and a control unit 4 for controlling the three; see Figure 9 , Figure 13 The auxiliary device 2 includes a plurality of carrying components 20 for loading raw materials of hair cakes, a first conveying component 21 which is at least provided on one side of the grouting device 1 and is used to transport the carrying components 20 into or out of the grouting device 1, and is installed on the grouting device 1. The moisturizing component 22 on the first conveying component 21 and located on the carrying component 20, the water replenishing component 23 arranged inside the first conveying component 21 and used to supplement moisture ...

Embodiment 2

[0085] A grouting method for making cakes, comprising the steps of:

[0086] S1 raw material assembly: Squeeze the prepared cake raw materials into each container, and place the carrying component on the first conveying component;

[0087] S2 Moisturizing of raw materials: When the carrying component is active on the first conveying component, the moisture inside the moisturizing component is squeezed out by the extrusion component and filled into each container;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com