Gas-film stepless variable damping device of gas static-pressure main shaft

A gas static pressure, variable damping technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve problems such as spindle heating, improve dynamic characteristics, improve accuracy and work adaptability, and improve system stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Referring to the attached picture:

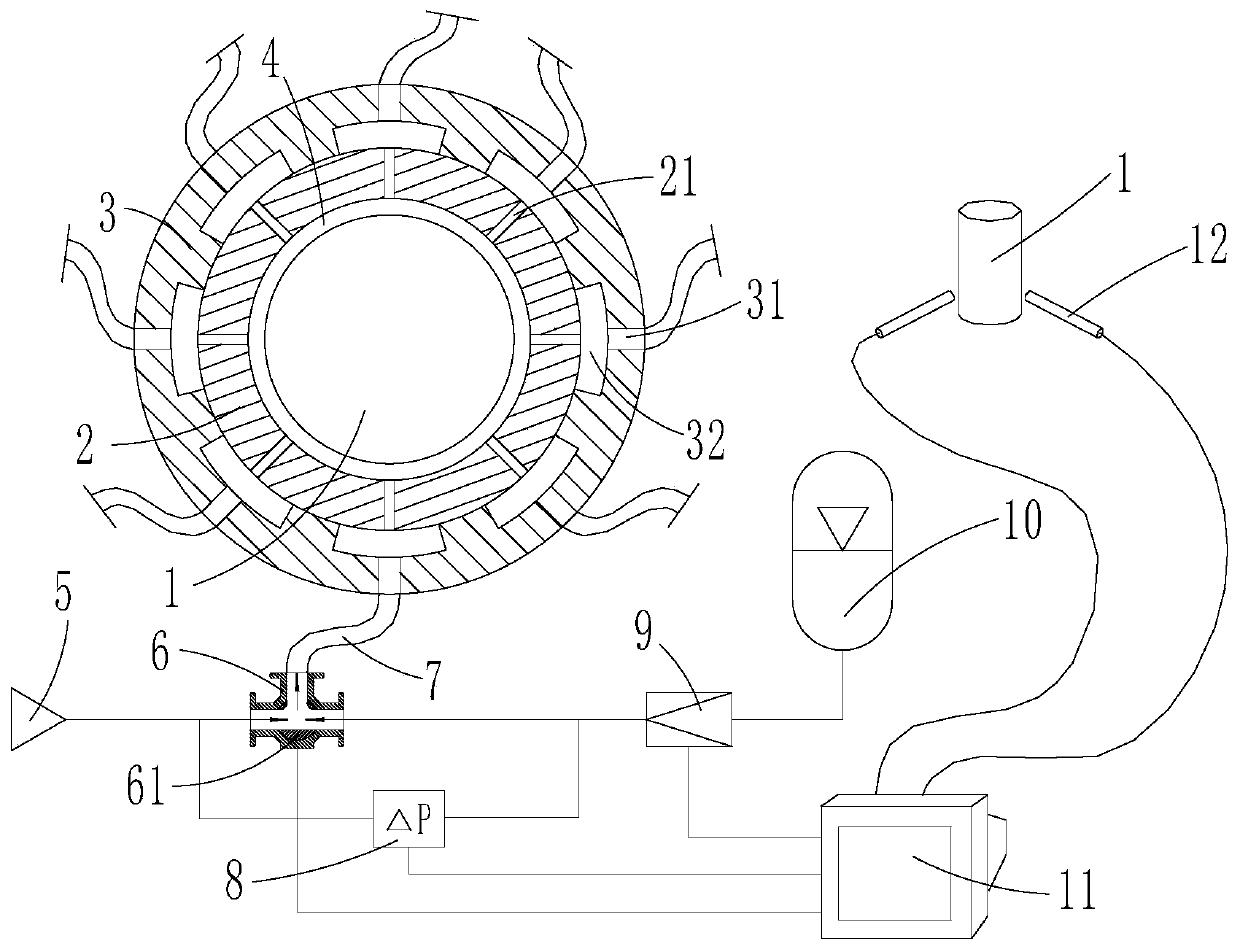

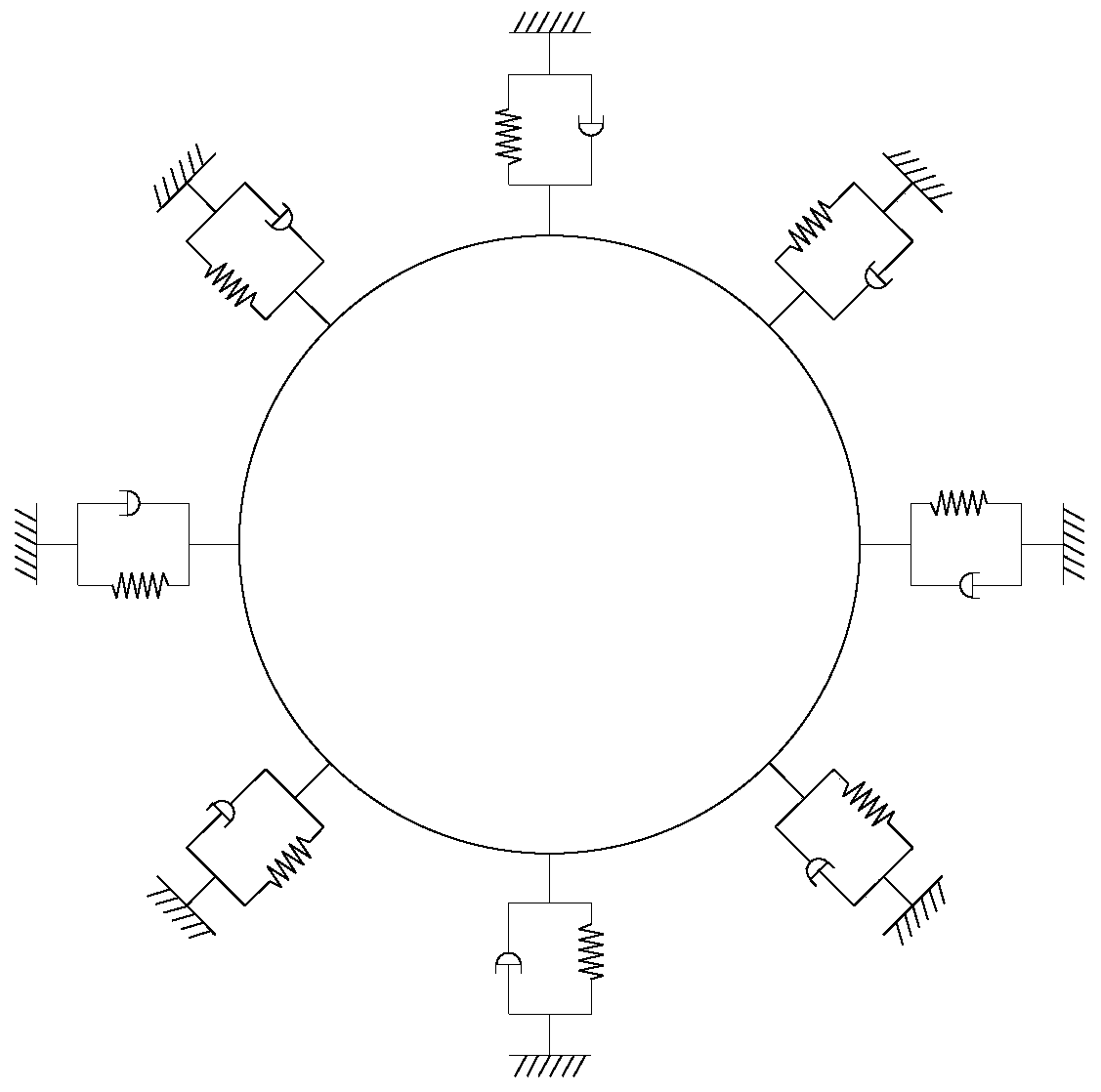

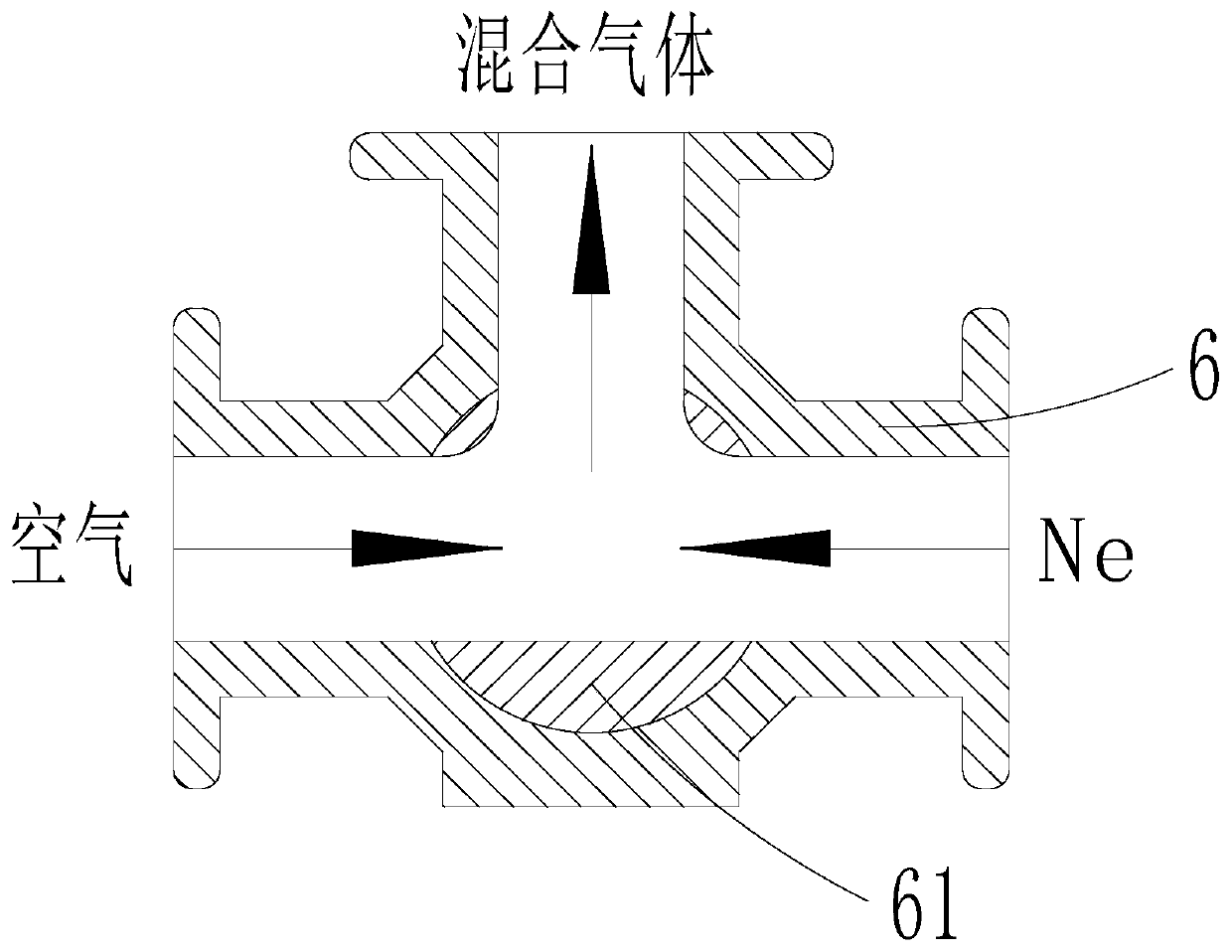

[0022] In the gas static pressure spindle stepless damping device described in the present invention, the bushing 2 is installed coaxially with the spindle 1, and the gap between the bushing 2 and the spindle 1 forms an air film 4, providing the spindle 1 with support. The air outer sleeve 3 is fitted on the outer wall of the shaft sleeve 2, and the inner wall of the air outer sleeve 3 is evenly distributed with a number of protruding contact parts along the circumferential direction. 32. The contact part is in sealing connection with the outer wall of the shaft sleeve 2. The air chamber 32 communicates with the air film 4 through the orifice 21, and the wall surface of the air outer sleeve 3 where the air chamber 32 is located has a through air inlet 31, and the air inlet 31 is connected to the T-shaped three-way ball va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com