Lifting mechanism, lifting platform device, photoetching machine and photoetching method

A lifting mechanism and limit mechanism technology, applied in the field of lifting table device and lifting mechanism, can solve the problems of far distance, the lifting table system can not meet the demand difference, and the lifting table system cannot be manufactured, so as to improve the lithography effect and high efficiency and reliability, the overall structure is simple and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

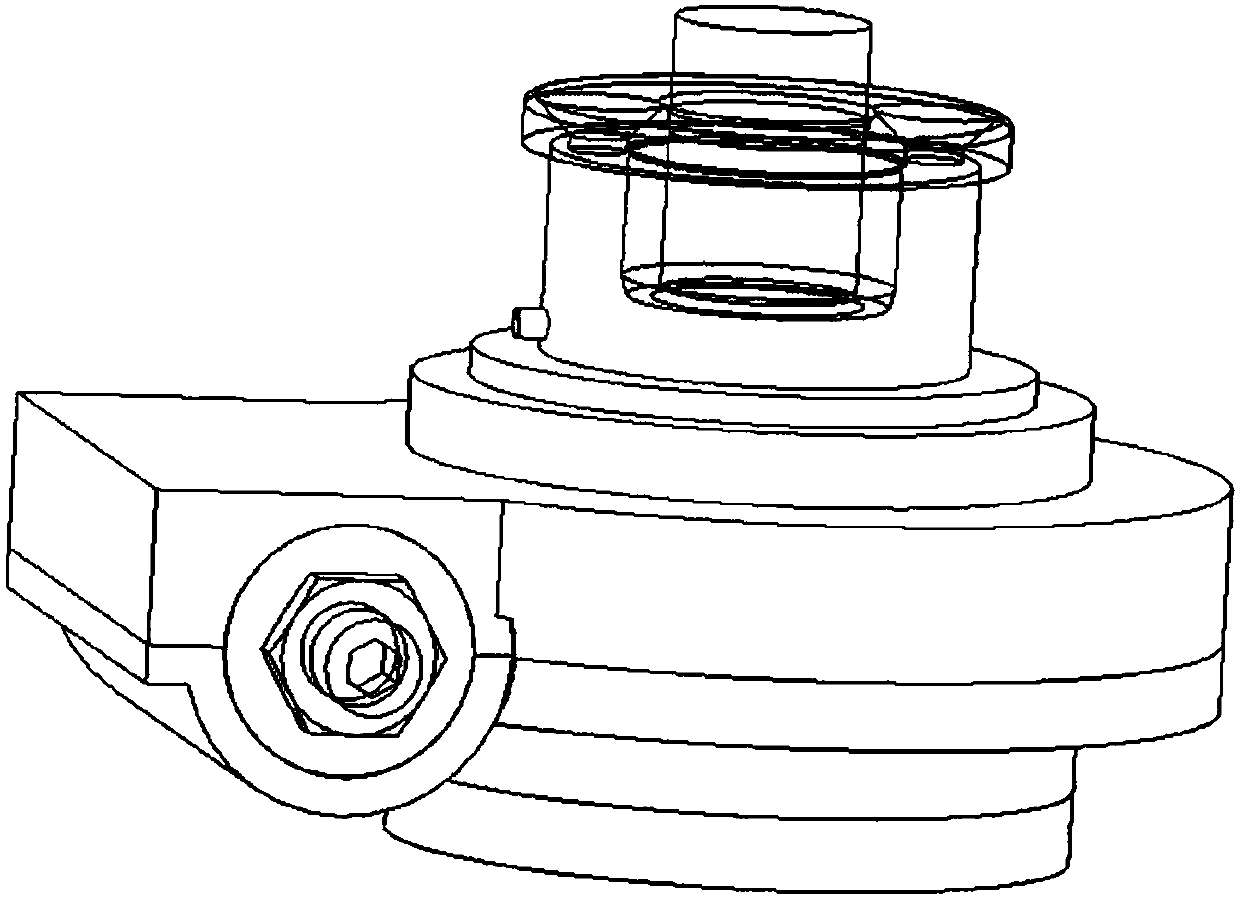

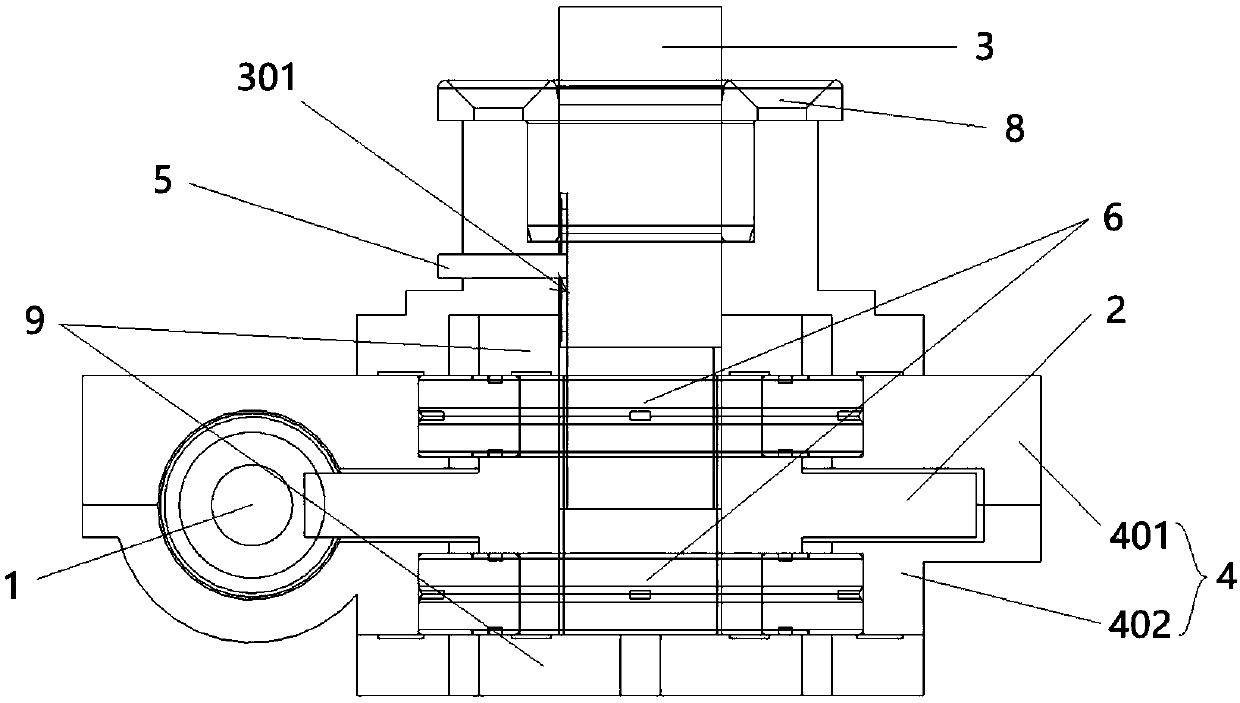

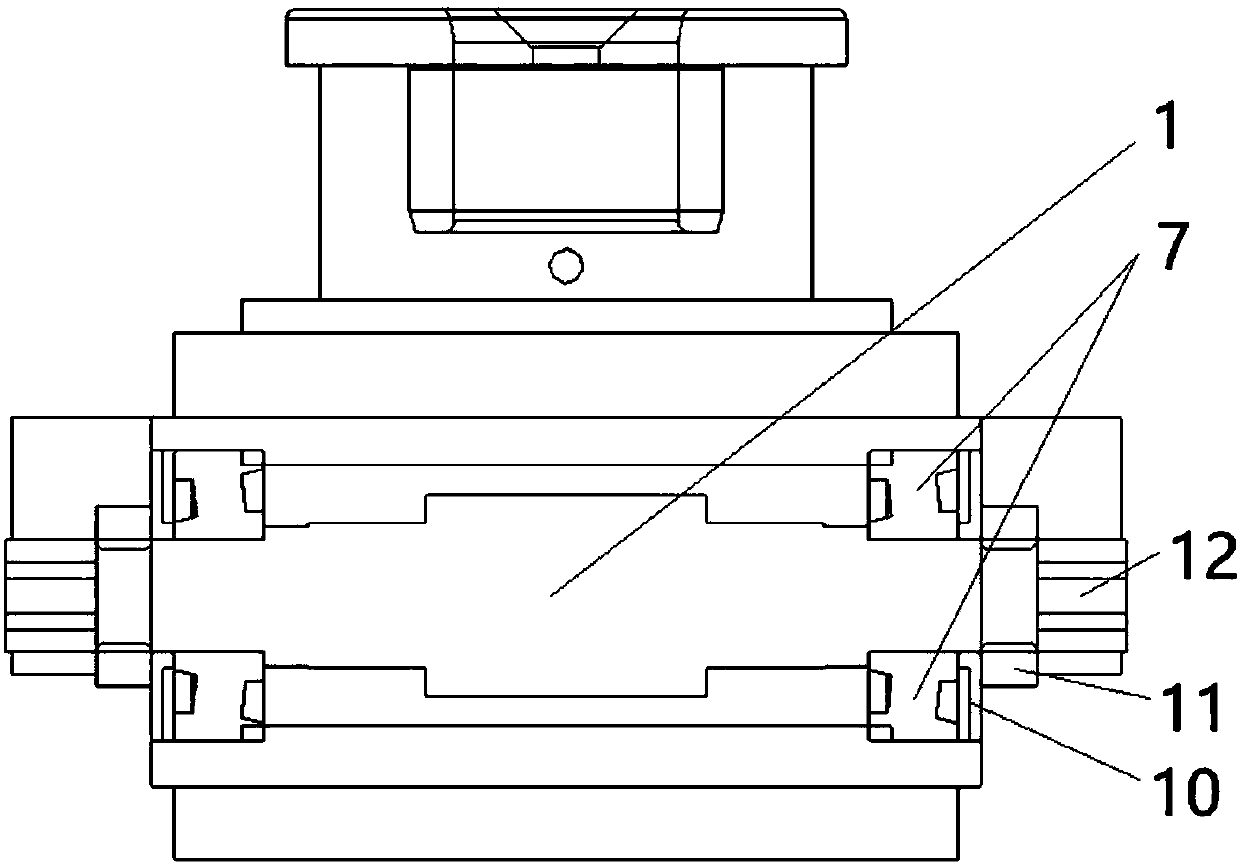

[0037] first, figure 1 The overall structural diagram of the lifting mechanism in Embodiment 1 of the present invention, figure 2 It is a structural schematic diagram of the transmission mechanism in Embodiment 1 of the present invention, image 3 and Figure 4 It is a cross-sectional view of the lifting mechanism in Embodiment 1 of the present invention, and it is referred to below Figure 1 to Figure 4 As shown, a lifting mechanism is provided in this embodiment, and the lifting mechanism includes a box 4, a worm 1, a worm wheel 2 and a screw 3; the worm 1 and the worm wheel 2 are arranged in the box 4 , the worm 1 is mated with the external thread of the worm wheel 2, the internal thread of the worm wheel 2 is sleeved on the screw 3, and the screw 3 is vertically arranged and extends from the box 4 ; When the worm 1 rotates, the worm wheel 2 is driven to rotate, and the screw 3 is driven to move up and down in the vertical direction through the rotation of the worm whee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com