Non-steel seamless bridge expansion joint device and construction technology thereof

A technology of seamless bridges and expansion joints, applied in bridges, bridge parts, bridge construction, etc., can solve problems affecting driving speed, comfort and safety, long repair time, difficulties, etc., to achieve safe and practical overall structural design, save Steel and concrete materials, the effect of convenient structure maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

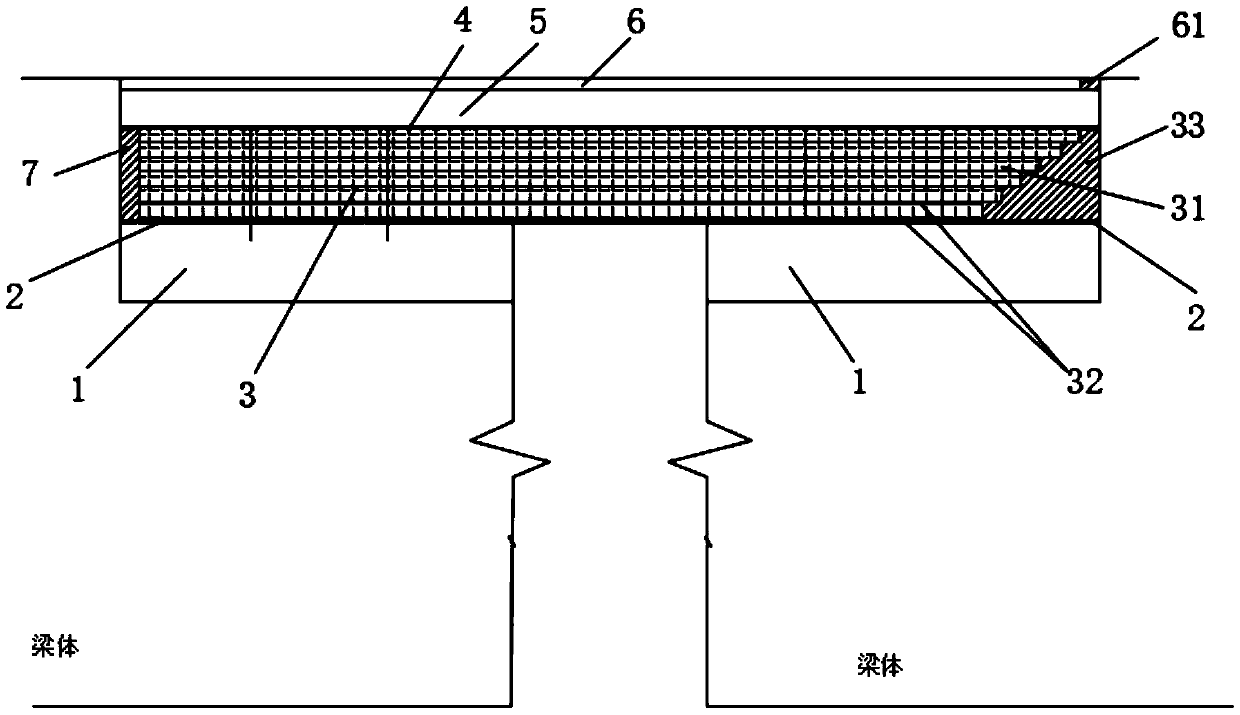

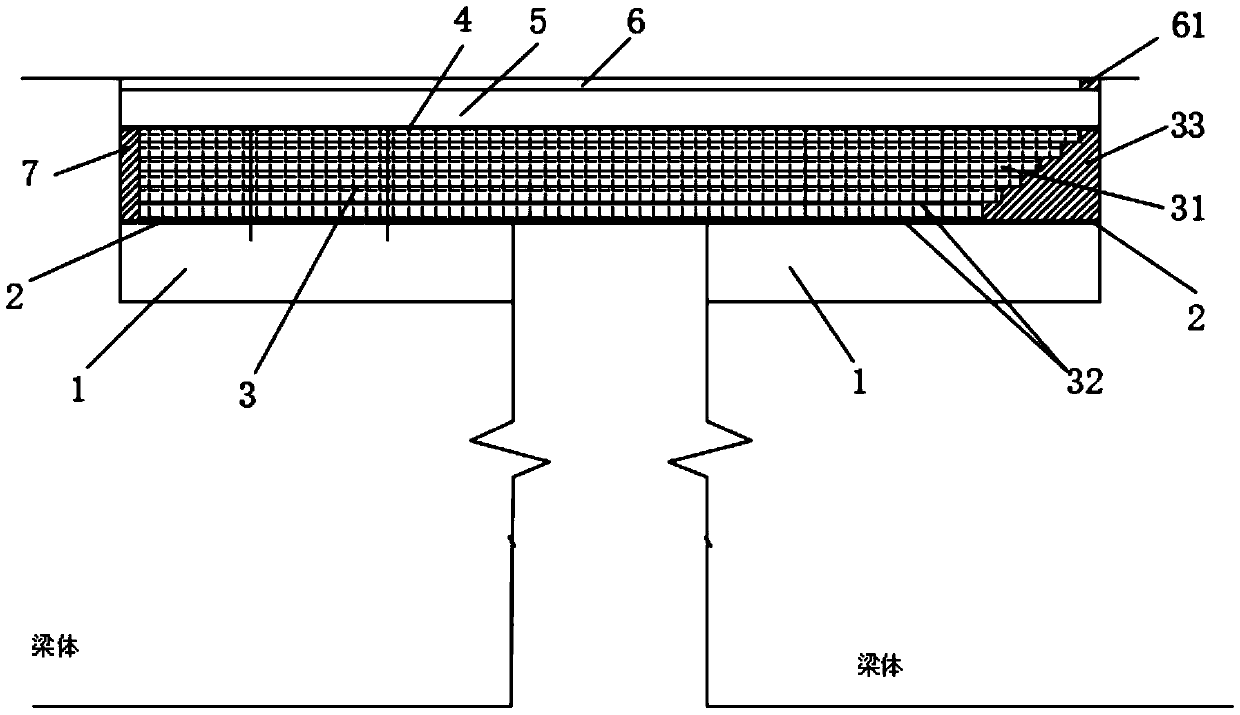

[0028] A steelless seamless bridge expansion joint device installed between two girder ends, the expansion joint device mainly includes a leveling layer 1, a waterproof layer 2, a telescopic Layer 3, sticky layer 4, asphalt pavement layer 5 and wear surface layer 6, wherein the leveling layer 1 is a high-strength mortar layer arranged at the bottom to bear the upper part, and is laid on the ends of the two beams on both sides of the expansion joint Form a leveling layer 1; the waterproof layer 2 is an asphalt waterproof protective sliding layer, laid on the surface of the two leveling layers 1, and the waterproof layer 2 on the surface of the two leveling layers 1 is laid horizontally; the telescopic layer 3 is a composite layer structure, the telescopic layer 3 includes a telescopic carrier layer 31 and stress release layers 33 on both sides; the sticky layer 4, asphalt pavement layer 5, and wear surface layer 6 are sequentially laid on the telescopic layer 3, and the wear lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com