Cooling structure of bearing unit

A technology of cooling structure and bearing device, which is applied in the direction of bearing cooling, bearing assembly, bearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

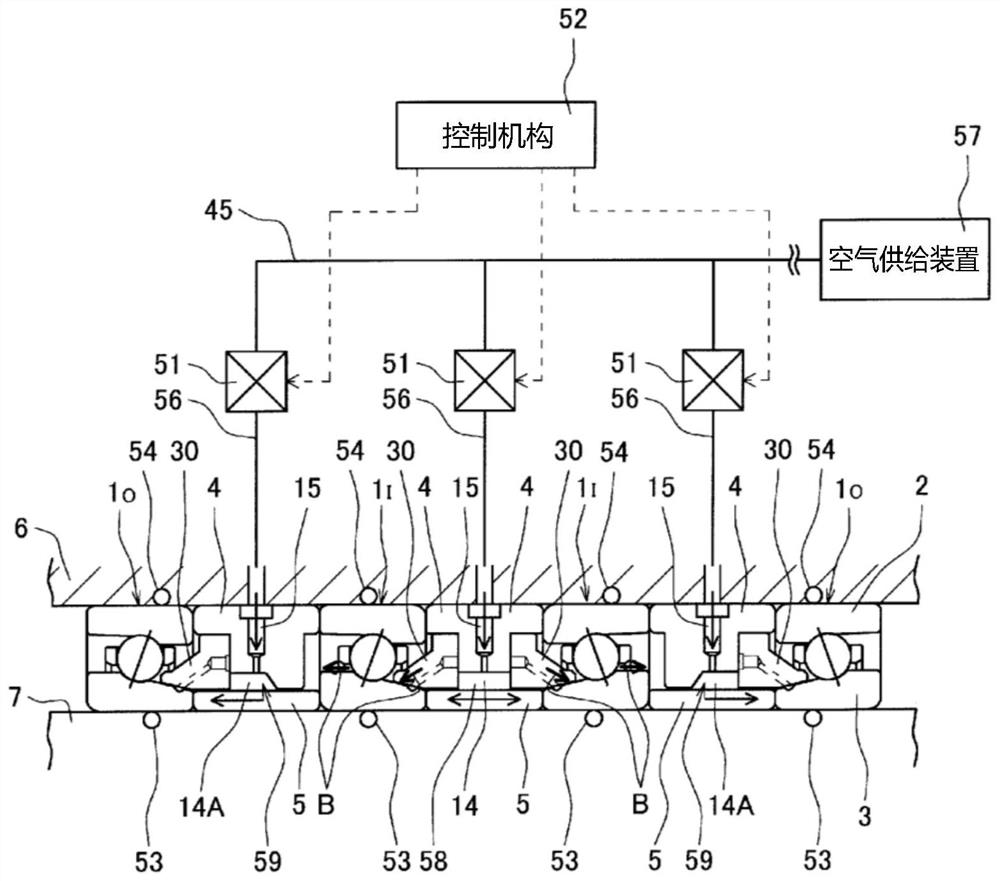

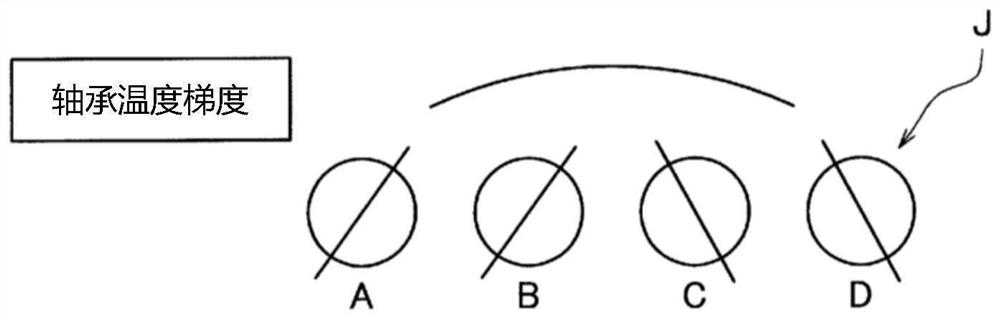

[0049] according to Figure 1 to Figure 8 , the first embodiment of the present invention will be described. picture figure 1 As shown, in the cooling structure of the bearing device J, the outer surfaces of the adjacent rolling bearings 1, 1 in the arrangement of the rolling bearings 1 arranged in three or more rows (in the illustrated example, four rows) in the axial direction are An outer ring spacer 4 and an inner ring spacer 5 are interposed between the rings 2, 2 and between the inner rings 3, 3, respectively. The outer ring 2 and the outer ring spacer 4 are provided on the inner periphery of the housing 6 , and the inner ring 3 and the inner ring spacer 5 are fitted on the outer periphery of the main shaft 7 as the rotation axis.

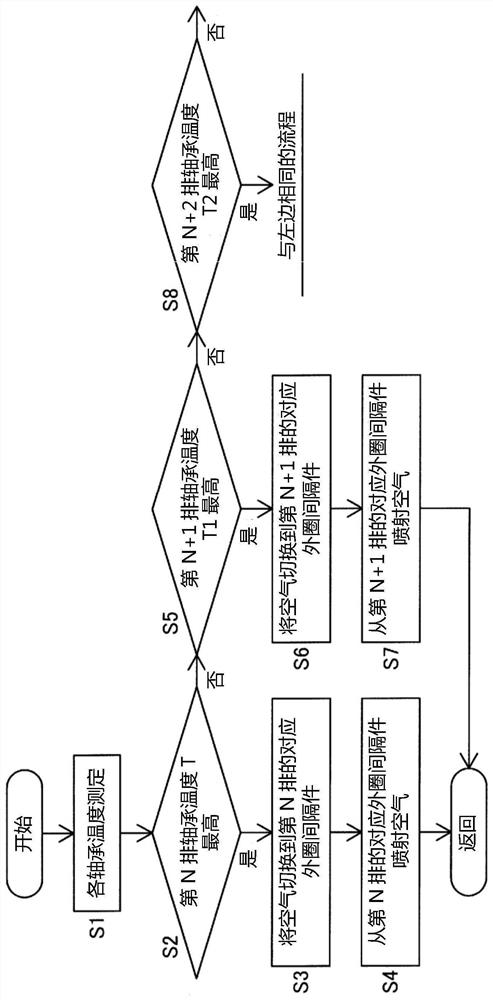

[0050] An air nozzle 15 is arranged on the above-mentioned outer ring spacer 4 , and the air nozzle 15 sprays compressed air to the inner ring spacer 5 opposite to each other. In addition, a valve body 51 is arranged, which adjusts the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com