A kind of preparation method and application of hydroxyl-containing ultraviolet absorber

A technology for ultraviolet rays and absorbers, which is applied in the preparation and application of hydroxyl-containing ultraviolet absorbers, can solve the problems of decreased ultraviolet protection ability and unstable alcohol solution, etc., and achieves the effects of excellent experience, strong sunscreen ability, and reduced application times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

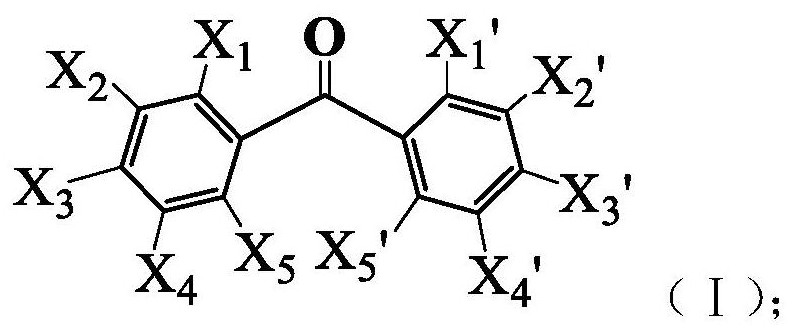

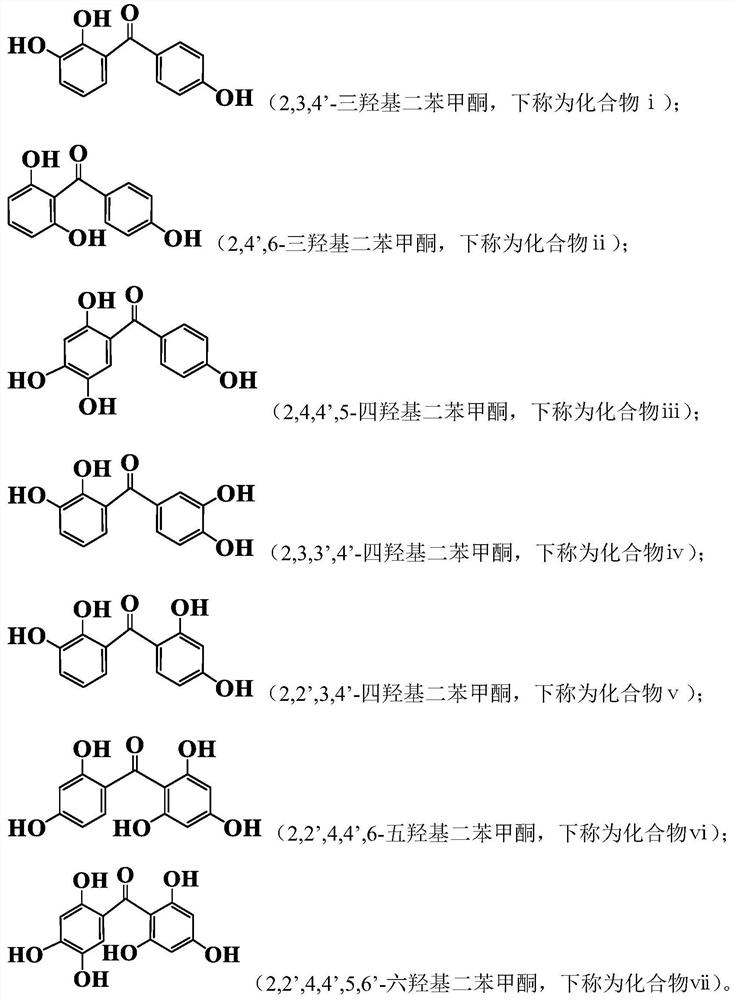

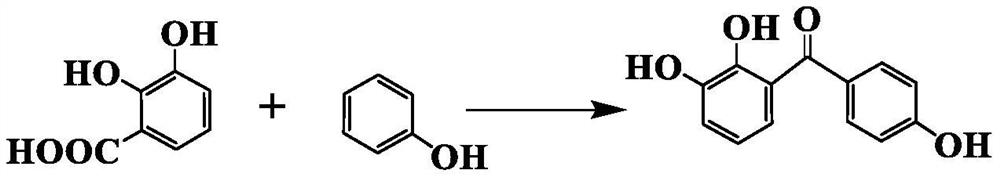

[0054] Preparation Example 1 (compound i——synthesis of 2,3,4'-trihydroxybenzophenone)

[0055]

[0056] Into a 250mL three-neck flask, add 11.8g of phenol, 15.3g of 2,3-dihydroxybenzoic acid, 23g of anhydrous zinc chloride, 19mL of phosphorus oxychloride, and 25mL of sulfolane in sequence. Stir and heat to raise the temperature of the material to 75-80°C, and react for about 2 hours until hydrogen chloride gas is observed to be released during the reaction. Slowly add 20mL of pure water to the reaction flask and stir well. Pour the mixture into 800mL of cold water and stir well. Let stand for more than 30 minutes, filter with suction, wash with water, and dry to obtain a crude product. Add the crude product into the solvent, heat to dissolve, add an appropriate amount of activated carbon, boil for 30 minutes, filter while it is hot, cool the filtrate, precipitate red powder, filter with suction, and dry to obtain the final product. Yield 85.4%.

preparation Embodiment 2

[0057] Preparation Example 2 (compound ii——2,4 ', the synthesis of 6-trihydroxybenzophenone)

[0058]

[0059] Into a 250mL three-neck flask, add 12.5g of phenol, 15.3g of 2,6-dihydroxybenzoic acid, 23g of anhydrous zinc chloride, 19mL of phosphorus oxychloride, and 25mL of sulfolane. Stir and heat to raise the temperature of the material to 75-80°C, and react for about 2 hours until hydrogen chloride gas is observed to be released during the reaction. Slowly add 20mL of pure water to the reaction flask and stir well. Pour the mixture into 800mL of cold water and stir well. Let stand for more than 30 minutes, filter with suction, wash with water, and dry to obtain a crude product. Add the crude product into the solvent, heat to dissolve, add an appropriate amount of activated carbon, boil for 30 minutes, filter while it is hot, cool the filtrate, precipitate red powder, filter with suction, and dry to obtain the final product. Yield 82.2%.

preparation Embodiment 3

[0060] Preparation Example 3 (Compound III——2,4,4', the synthesis of 5-tetrahydroxybenzophenone)

[0061]

[0062] Into a 250 mL three-neck flask, add 12.0 g of phenol, 17.0 g of 2,4,5-trihydroxybenzoic acid, 23 g of anhydrous zinc chloride, 19 mL of phosphorus oxychloride, and 25 mL of sulfolane in sequence. Stir and heat to raise the temperature of the material to 75-80°C, and react for about 2 hours until hydrogen chloride gas is observed to be released during the reaction. Slowly add 20mL of pure water to the reaction flask and stir well. Pour the mixture into 800mL of cold water and stir well. Let stand for more than 30 minutes, filter with suction, wash with water, and dry to obtain a crude product. Add the crude product into the solvent, heat to dissolve, add an appropriate amount of activated carbon, boil for 30 minutes, filter while it is hot, cool the filtrate, precipitate red powder, filter with suction, and dry to obtain the final product. Yield 82.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com