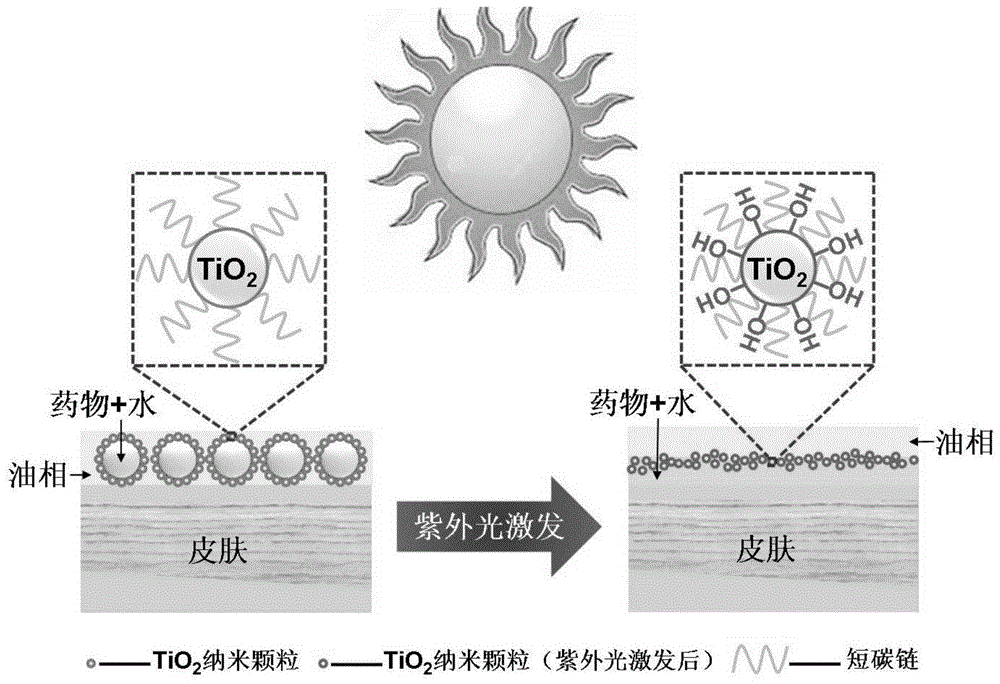

A kind of preparation technology of uv controlled-release medicinal ingredient and easy-to-clean pickering emulsion type sunscreen

A medicinal ingredient and preparation technology, applied in the field of sunscreen cosmetics and fine chemical industry, can solve the problems of unavoidable side effects and irritation, lack of drug controlled release ability, affect the stability of emulsion, etc., and achieve the effect of controlled drug release. , Strong sun protection effect, good sun protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: TiO 2 Preparation method of nanoparticle surfactant

[0023] (a) TiO 2 Preparation of nanoparticles: Add 36 mL of absolute ethanol to 9 mL of butyl titanate and keep stirring to obtain a mixed solution A; add 12 mL of deionized water to 40 mL of glacial acetic acid and keep stirring to get a mixed solution B. Add the mixed solution B dropwise to the stirred mixed solution A to prepare a transparent sol (the sol can be doped with N elements to adjust the light response time and intensity). Transfer the transparent sol to a hydrothermal synthesis reaction kettle for a constant temperature reaction at 150°C, the reaction time is 2 hours, remove the supernatant, and obtain white TiO 2 precipitation. Wash the white TiO with absolute ethanol 2 Precipitate, 15000rpm high-speed centrifugation for 10 minutes, repeat the above operation 3 times, discard the supernatant, collect the precipitate, then add absolute ethanol to fully disperse, and dry in an oven at 60°C to...

Embodiment 2

[0030] Step 1: TiO 2 Preparation method of nanoparticle surfactant

[0031] (a) TiO 2 Preparation of nanoparticles: Add 36 mL of absolute ethanol to 9 mL of butyl titanate and keep stirring to obtain a mixed solution A; add 12 mL of deionized water to 40 mL of glacial acetic acid and keep stirring to get a mixed solution B. Add the mixed solution B dropwise to the stirred mixed solution A to obtain a transparent sol. Transfer the transparent sol to a hydrothermal synthesis reaction kettle for a constant temperature reaction at 150°C. The reaction time is 2 hours. Remove the supernatant to obtain white TiO 2 precipitation. Wash the white TiO with absolute ethanol 2 Precipitate, 15000rpm high-speed centrifugation for 10 minutes, repeat the above operation 3 times, discard the supernatant, collect the precipitate, then add absolute ethanol to fully disperse, and dry in an oven at 60°C to obtain relatively pure TiO 2 precipitation. The dried TiO 2 The precipitate was fully ...

Embodiment 3

[0038] The oil phase is replaced with No. 26 white oil of cosmetic grade, and other steps are as described in Example 1 and Example 2.

[0039] After diluting the self-made Pickering emulsion sunscreen and the traditional organic sunscreen to the same multiple, the absorbance was measured respectively. According to the drawn ultraviolet wavelength scanning chart, the self-made Pickering emulsion sunscreen has better sun protection effect than the traditional organic sunscreen. This is due to the TiO in homemade Pickering lotion-based sunscreens 2 Nanoparticles can not only reflect and scatter ultraviolet rays, but also have a strong absorption effect on ultraviolet rays. At the same time, the self-made Pickering emulsion sunscreen and the traditional organic sunscreen were applied to the same carrier in equal doses, and the residues were cleaned after equal time and intensity of light, and the cleaning effect of the self-made Pickering emulsion sunscreen was obvious. The main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com