Wheat flour production break device

A kind of skin milling and wheat technology, applied in application, solid separation, filtering and screening, etc., can solve the problems of complicated procedures, high cost, complex and huge equipment, etc., to reduce screening work, reduce labor costs, and increase floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

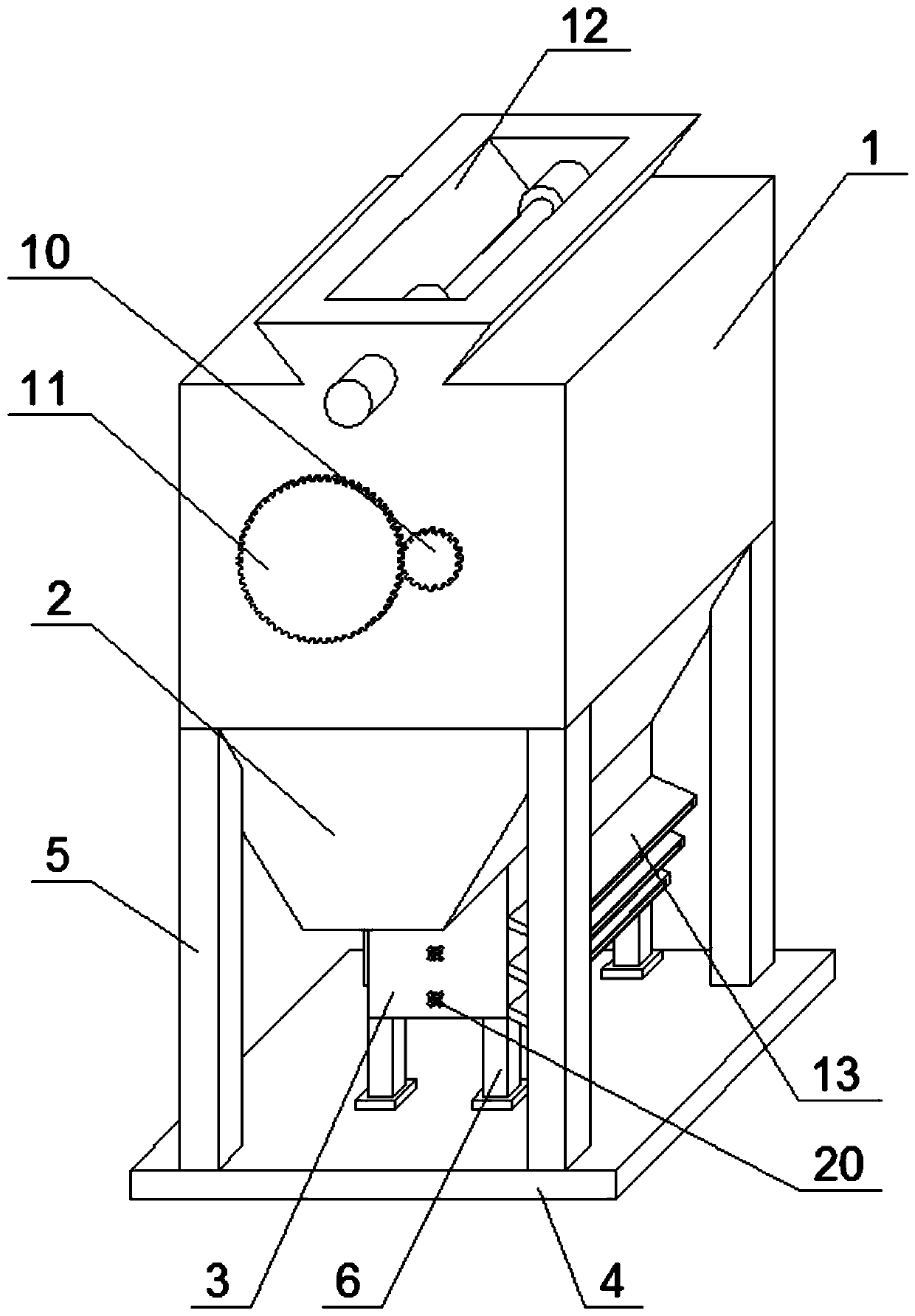

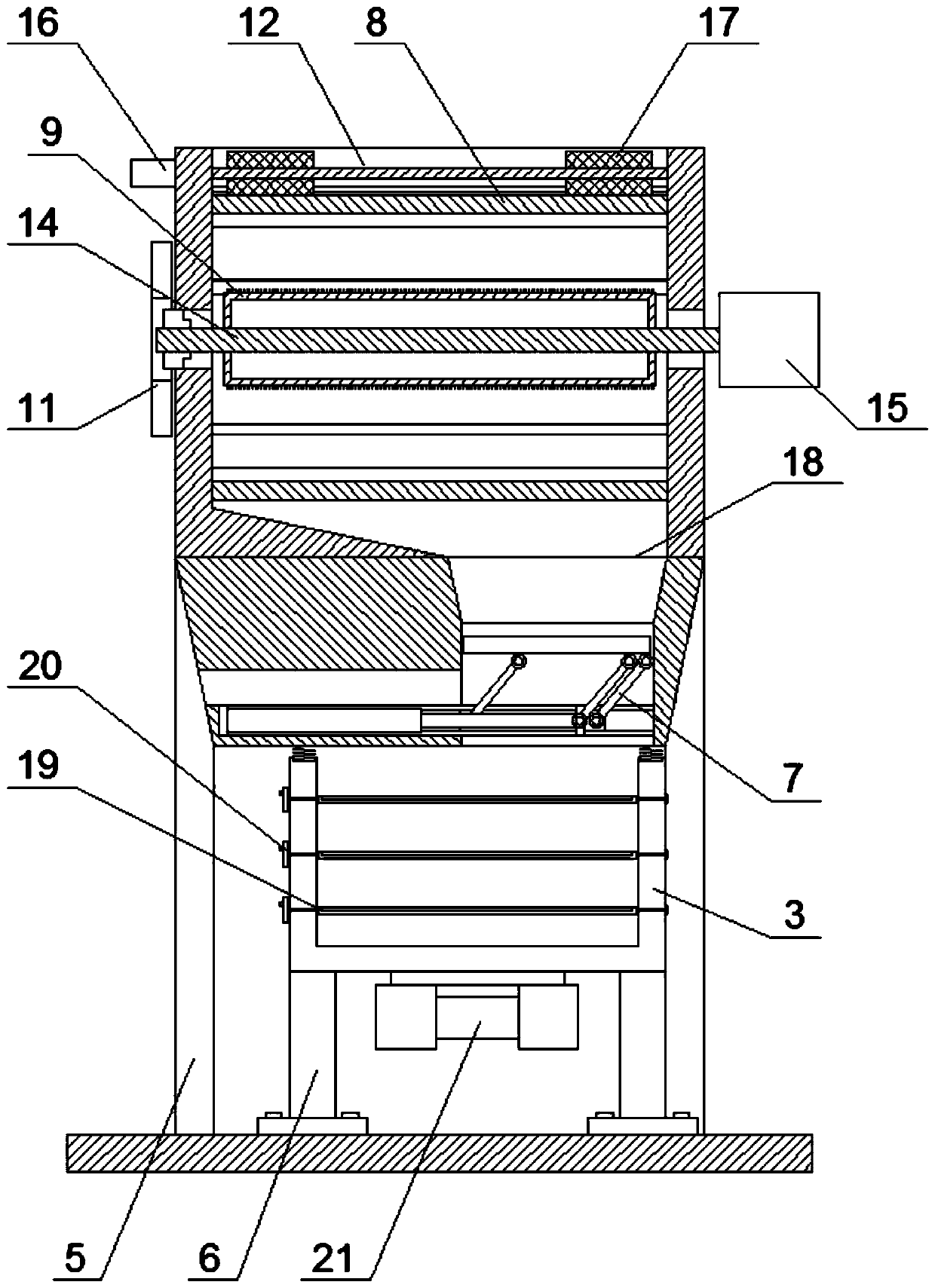

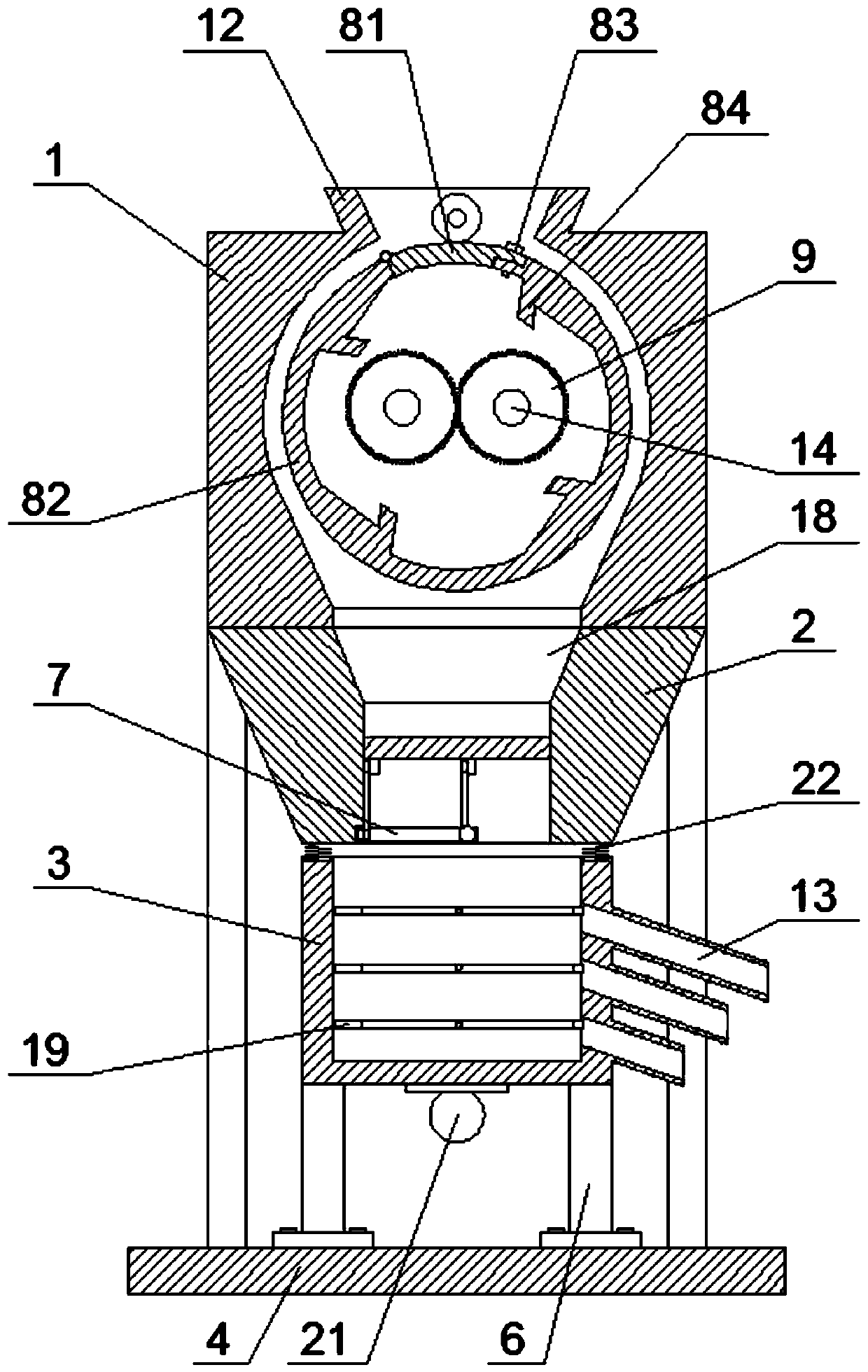

[0027] Such as Figure 1 to Figure 4 As shown, the skin grinding device for wheat flour milling provided in this embodiment includes a base 4, a skin grinding mechanism installed on the base 4 through the legs 5, a screening box 3 installed on the base 4 through the legs 6, the mill The skinning mechanism includes a skinning box 1 and a material receiving box 2 fixed on the lower surface of the skinning box 1. The top of the skinning box 1 is provided with a feed inlet 12, and the bottom of the skinning box 1 is provided with a discharge port, and the skinning box 1 is provided with a discharge port. 1 is provided with a set of toothed rollers 9 for wheat husk grinding. In this embodiment, in order to be different from the structure of traditional toothed rollers, the set of toothed rollers 9 includes two first toothed rollers and a second toothed roller with the same shape and size that rotate in opposite directions. Two toothed rollers, the first toothed roller and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com