Silver melting surface pretreatment device with high adaptability

A processing device and adaptable technology, which are used in secondary processing of printed circuits, cleaning/polishing of conductive patterns, and improvement of metal adhesion of insulating substrates, etc. Consumption and other issues, to achieve the effect of improving space utilization, increasing floor space, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific embodiments, structures, features and effects of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

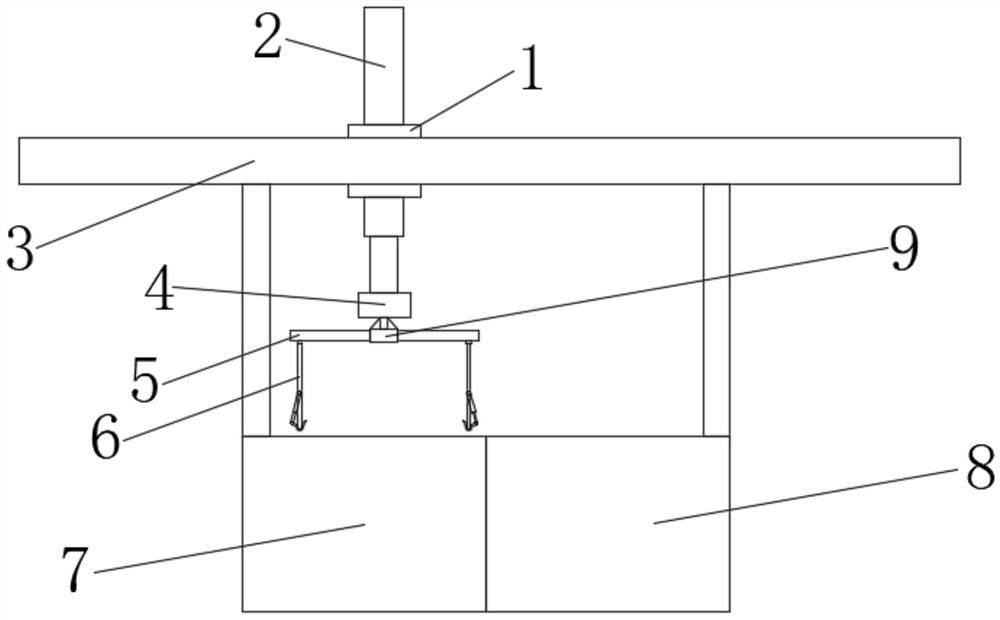

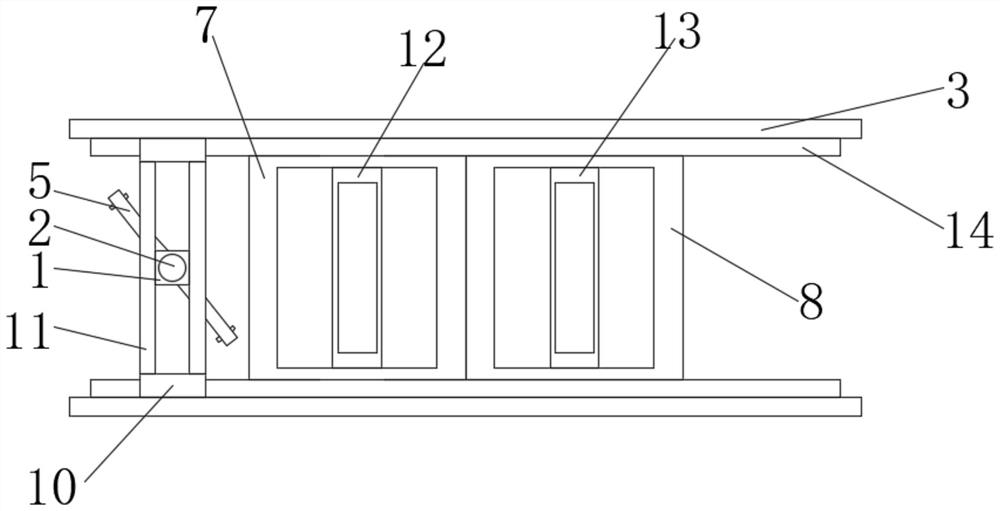

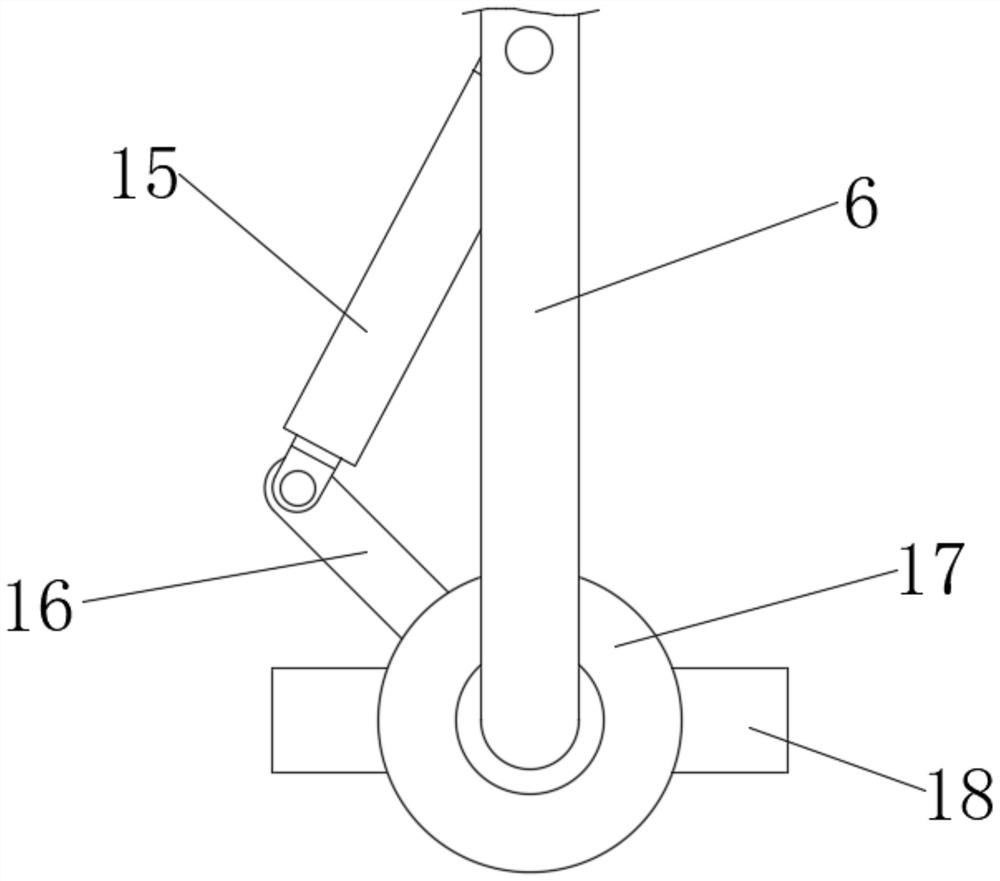

[0034] see Figure 1-9 Shown: a highly adaptable silver surface pretreatment device, comprising a support frame 3, a first installation box 7 and a second installation box 8, the second installation box 8 is arranged on one side of the first installation box 7, The first installation box 7 and the second installation box 8 are installed with support frames 3 on both sides above, and support guide rails 14 are installed on the upper opposite sides of the two support frames 3, and the linear motors 10 are installed on the support guide rails 14. The linear motors 10 are arranged symmetrically, two support slide rails 11 are installed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com