A kind of spherical polyaniline/graphene composite membrane material and its preparation method and application

A composite technology of spherical polyaniline and graphene, which is applied in the manufacture of hybrid/electric double layer capacitors, electrodes of hybrid capacitors, structural parts, etc. The effects of random stacking of sheets, enhanced ion penetration and charge transfer capabilities, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

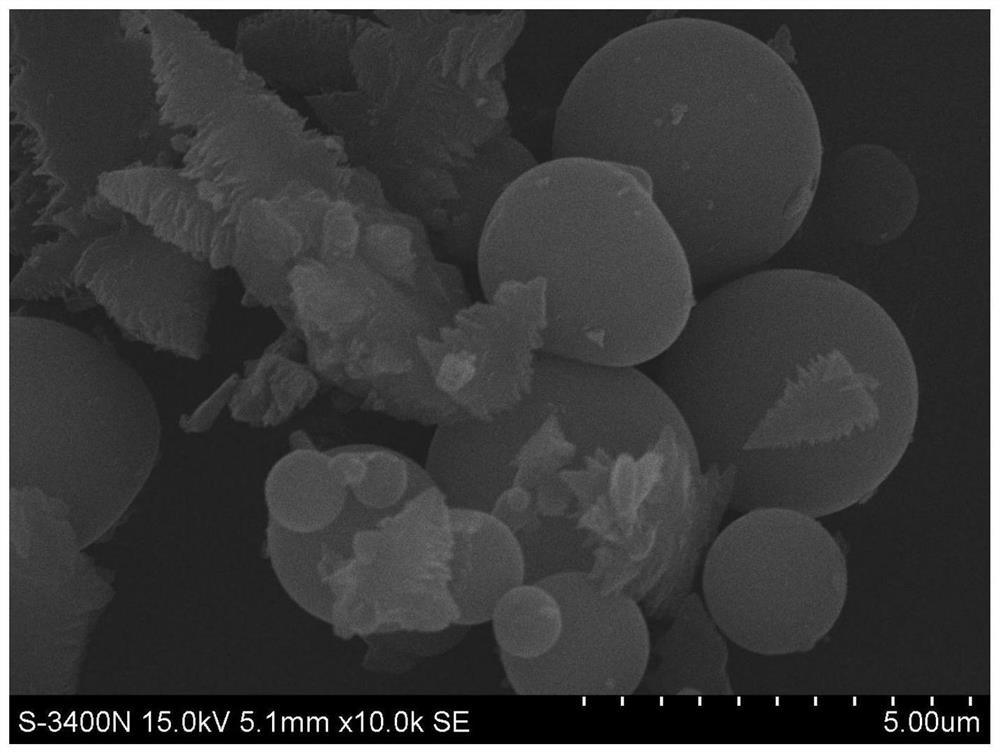

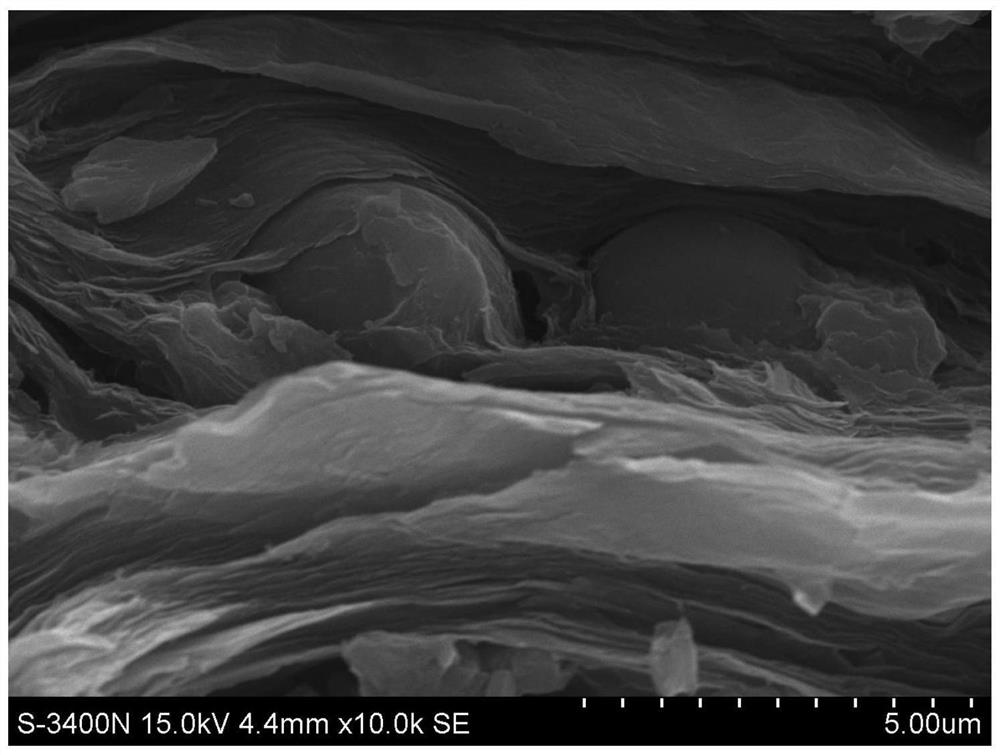

[0037] In an ice bath (5°C), add aniline, phenol, and sodium lauryl sulfate at a mass ratio of 1:10:0.01 to 0.1mol / L hydrochloric acid solution (the mass ratio of aniline to hydrochloric acid solution is 1:200) and mix and stir Dissolve, add oxidant ammonium persulfate (accounting for 100% of the mass of aniline), and react for 12 hours to obtain spherical polyaniline. Graphene oxide, spherical polyaniline and reducing agent ascorbic acid are added to the solvent (a mixture of water and ethanol with a mass ratio of 1:1) in a mass ratio of 100:10:10, wherein the mass ratio of solvent to graphene oxide is 100 : 1, Ultrasonic mixing for 1 hour, pour the dispersion obtained after mixing into a polytetrafluoroethylene mold, set the temperature at 60°C, and react for 2 hours to obtain a composite film. The added amount of spherical polyaniline accounted for 10% of graphene oxide. Using a three-electrode constant current charge and discharge test, the composite film has a specific m...

Embodiment 2

[0039] In an ice bath (3°C), add aniline, phenol, and sodium lauryl sulfate at a mass ratio of 1:5:0.05 to 0.1mol / L hydrochloric acid solution (the mass ratio of aniline to hydrochloric acid solution is 1:100) and stir to dissolve , adding the oxidant ammonium persulfate (accounting for 100% of the aniline mass), and reacting for 12 hours to obtain spherical polyaniline. Graphene oxide, spherical polyaniline and reducing agent ascorbic acid are added in the solvent (a mixture of water and ethanol with a mass ratio of 1:1) in a mass ratio of 100:20:10, wherein the mass ratio of solvent to graphene oxide is 100: 1. Ultrasonic mixing for 1 hour, pour the dispersion obtained after mixing into a polytetrafluoroethylene mold, set the temperature at 60°C, and react for 2 hours to obtain a composite film. The added amount of spherical polyaniline accounted for 20% of graphene oxide. Using a three-electrode constant current charge and discharge test, the composite film has a specific ...

Embodiment 3

[0041] In an ice bath (0°C), add aniline, phenol, and sodium dodecylsulfonate in a mass ratio of 1:2:0.02 to 0.1mol / L hydrochloric acid solution (the mass ratio of aniline to hydrochloric acid solution is 1:50) and mix and stir Dissolve, add oxidant ammonium persulfate (accounting for 100% of the mass of aniline), and react for 12 hours to obtain spherical polyaniline. Graphene oxide, spherical polyaniline and reducing agent ascorbic acid are added to the solvent (a mixture of water and ethanol with a mass ratio of 1:1) in a mass ratio of 100:30:10, wherein the mass ratio of solvent to graphene oxide is 100:1 , ultrasonically mixed for 1 hour, poured the mixed dispersion liquid into a polytetrafluoroethylene mold, set the temperature at 80°C, and reacted for 4 hours to obtain a composite film. The added amount of spherical polyaniline accounted for 30% of graphene oxide. Using a three-electrode constant current charge and discharge test, the composite film has a specific mass...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap