Moisturizing dust suppressant and preparation method thereof

A dust suppressant, wet-type technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of large water consumption, short dust retention time, etc., to increase the dust suppression cycle, prolong the dust suppression time, compatible good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

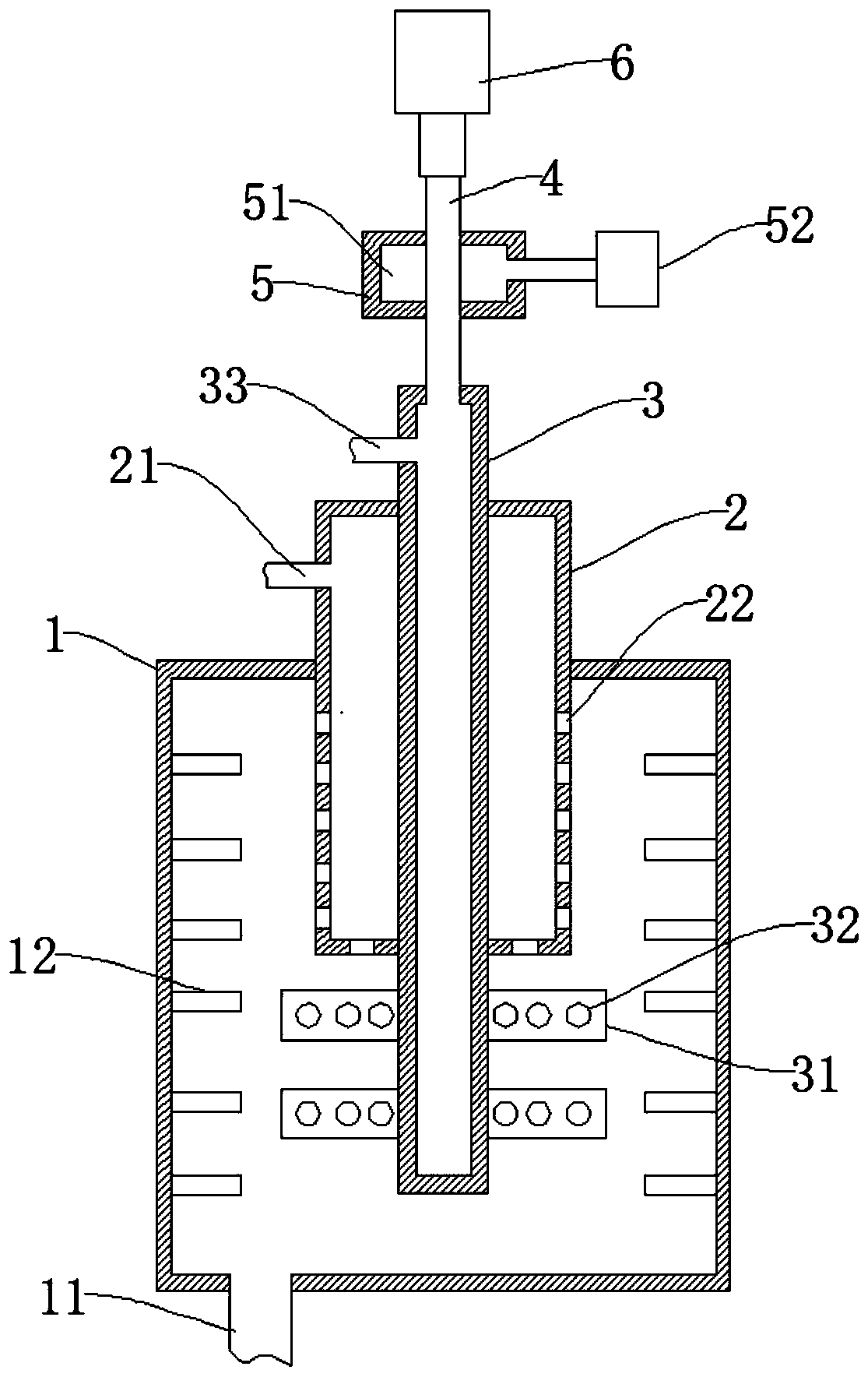

Method used

Image

Examples

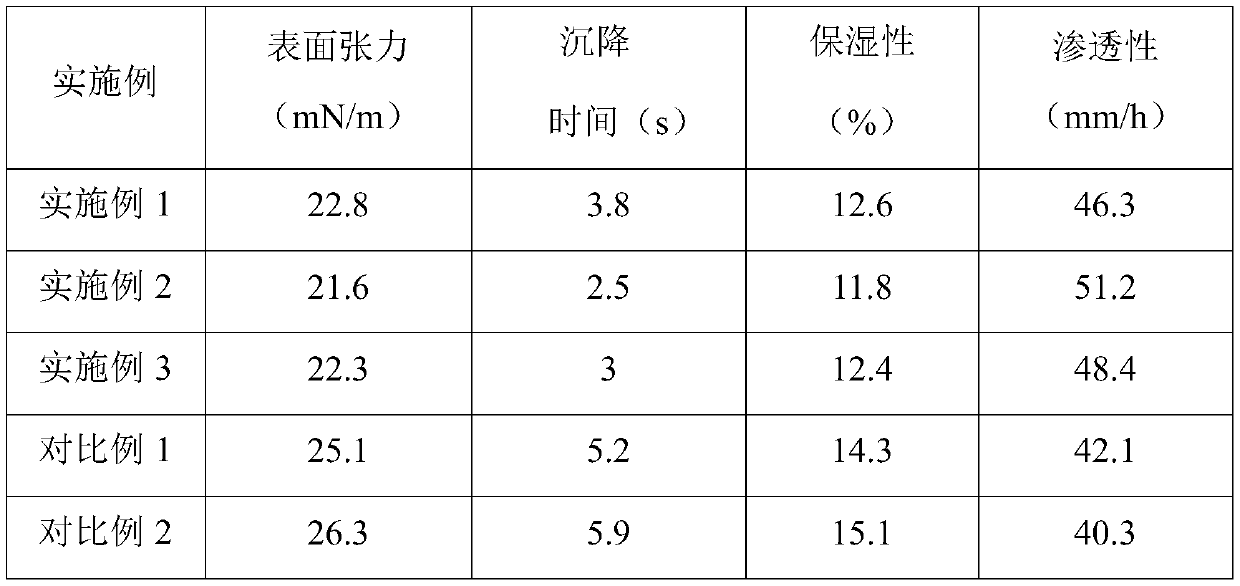

Embodiment 1

[0031] Moisturizing dust suppressant, comprising the following components by weight percentage:

[0032] Paraffin oil 4%, castor oil 1%, tricosanol 0.2%, pentacosanol 0.5%, octadecyl trichlorosilane 0.5%, lauryl alcohol 0.1%, polyvinyl alcohol 0.1%, inorganic salt additives 0.05%, filler 0.1%, the rest water;

[0033] Wherein, the preparation method of described filler is:

[0034] S1, put the mullite that is 5 parts by weight, 3 parts of volcanic stone pulverized and placed in the sulfuric acid solution of 2% mass concentration after soaking 5min, then be placed in the sodium hydroxide solution of 3% mass concentration and soak 10min , after filtering, set aside;

[0035] S2. Put 1 part by weight of corn stalks and 1 part of sugarcane stalks into an airtight container after crushing, feed water vapor to make the pressure in the airtight container 1Mpa, keep it for 1h, release the pressure to 15pa within 10s, and keep it for 2min , continue to feed water vapor to make the p...

Embodiment 2

[0049] Moisturizing dust suppressant, comprising the following components by weight percentage:

[0050] Paraffin oil 5%, castor oil 2%, tricosanol 0.4%, pentacosanol 0.8%, octadecyltrichlorosilane 0.8%, lauryl alcohol 0.3%, polyvinyl alcohol 0.3%, inorganic salt additives 0.08%, filler 0.3%, the rest water;

[0051] Wherein, the preparation method of described filler is:

[0052] S1, put the mullite that is 8 parts by weight, 4 parts of volcanic stone pulverized and placed in the sulfuric acid solution of 3% mass concentration after soaking 8min, then be placed in the sodium hydroxide solution of 4% mass concentration and soak 13min , after filtering, set aside;

[0053] S2. Put 1 part by weight of corn stalks and 2 parts of sugarcane stalks into an airtight container after pulverization, feed water vapor to make the pressure in the airtight container 1.2Mpa, keep it for 1.3h, and release the pressure to 18pa within 15s. Keep it for 3 minutes, continue to introduce water v...

Embodiment 3

[0067] Moisturizing dust suppressant, comprising the following components by weight percentage:

[0068] Paraffin oil 6%, castor oil 3%, tricosanol 0.6%, pentadecyl alcohol 1%, octadecyltrichlorosilane 1%, lauryl alcohol 0.5%, polyvinyl alcohol 0.5%, inorganic salt additives 0.1%, filler 0.5%, the rest water;

[0069] Wherein, the preparation method of described filler is:

[0070] S1, after pulverizing 10 parts by weight of mullite and 5 parts of volcanic rock, soak in a sulfuric acid solution with a mass concentration of 5% for 10 minutes, and then place it in a sodium hydroxide solution with a mass concentration of 3 to 6%. Soak for 15 minutes, filter and set aside;

[0071] S2. After pulverizing 2 parts by weight of corn stalks and 2 parts of sugarcane stalks, place them in a closed container, feed water vapor to make the pressure in the closed container 1.5 Mpa, keep it for 1.5 hours, and then release the pressure to 20 Pa within 20 seconds. Keep it for 5 minutes, cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com