High-silicon steel plate modified by rare-earth yttrium and production method thereof

A steel plate modification technology, applied in the field of high-silicon steel, can solve the problems of no high-silicon steel plate preparation method, late development and application, and high price, so as to reduce the generation of ordered phases, reduce the formation of internal oxide layers, and effectively Good for removing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

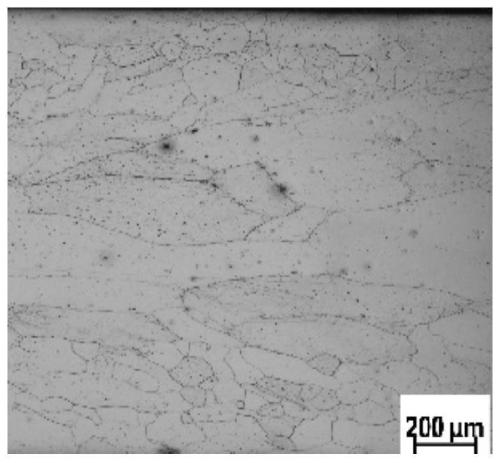

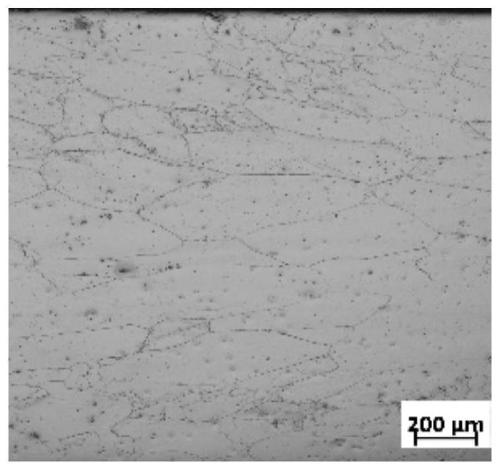

Image

Examples

preparation example Construction

[0058] The preparation method of the above-mentioned rare earth yttrium-modified high-silicon steel plate is as follows:

[0059] Step 1 Slab production: vacuum induction melting is used to cast the steel ingot with the above chemical composition, and the steel ingot is forged at 800° C. to 1050° C. to obtain a slab of 20 to 30 mm.

[0060] Step 2 hot rolling: heat the slab in step 1 at 1100° C. for 30-40 minutes, and perform hot rolling at 850° C.-1100° C. to obtain a hot-rolled sheet of 1.8-2.2 mm.

[0061] Step 3 Normalization (i.e. normalizing treatment): heat the hot-rolled sheet in step 2 at 850°C-950°C for 120-180s, and then cool it to room temperature in an oil medium (i.e. oil quenching) to obtain a normalized sheet.

[0062] Step 4 Warm rolling: Deoxidize the normalized sheet obtained in step 3, and then perform rolling at 450°C-500°C to obtain a warm-rolled sheet with a thickness of 0.4-0.5mm.

[0063] Step 5 intermediate annealing: heat the warm-rolled sheet obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com