High-strength non-dismantling formwork and manufacturing method thereof

A technology that avoids dismantling formwork and formwork. It is applied in the direction of manufacturing tools, building structures, building reinforcements, etc. It can solve the problems of cracking, falling off, and bulging on the wall surface, so as to reduce manufacturing costs, meet market demand, and meet technical requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

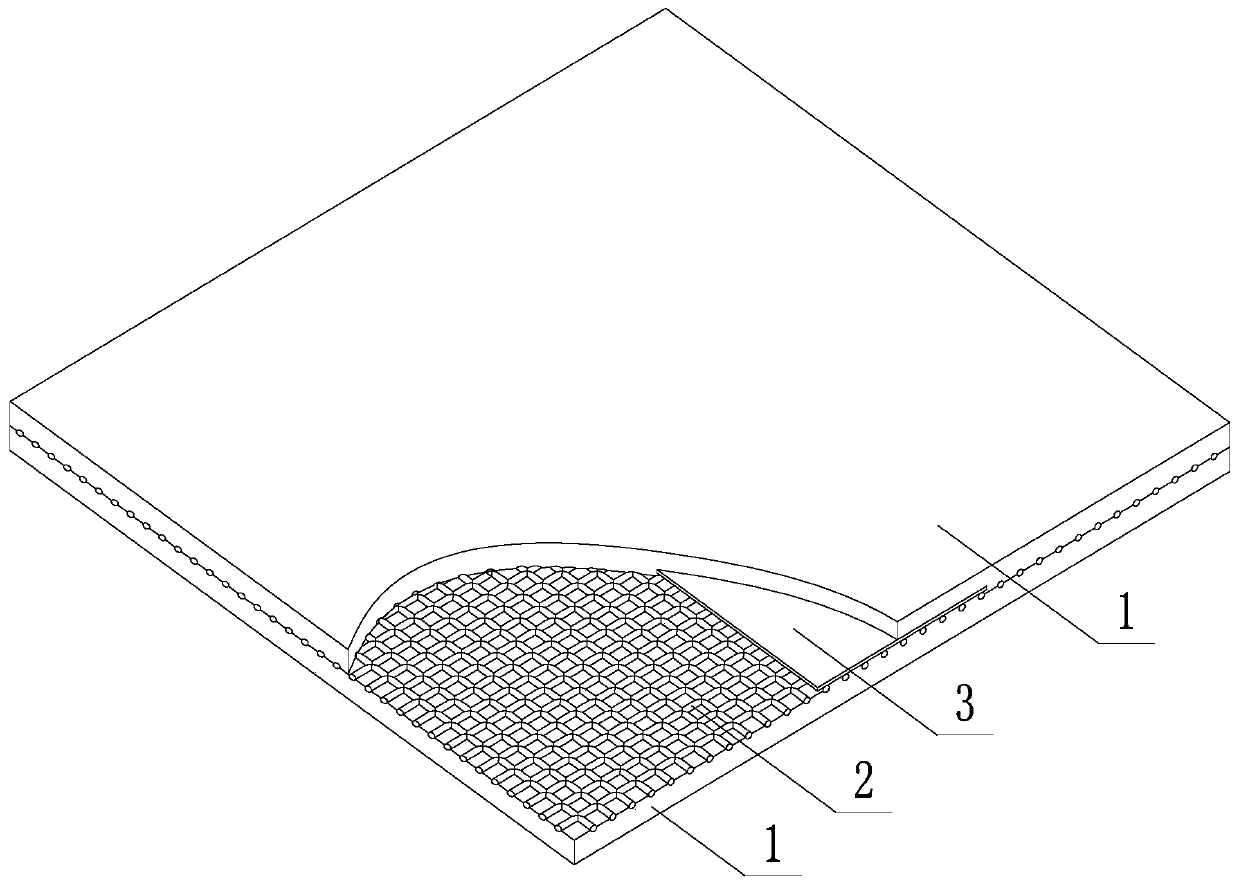

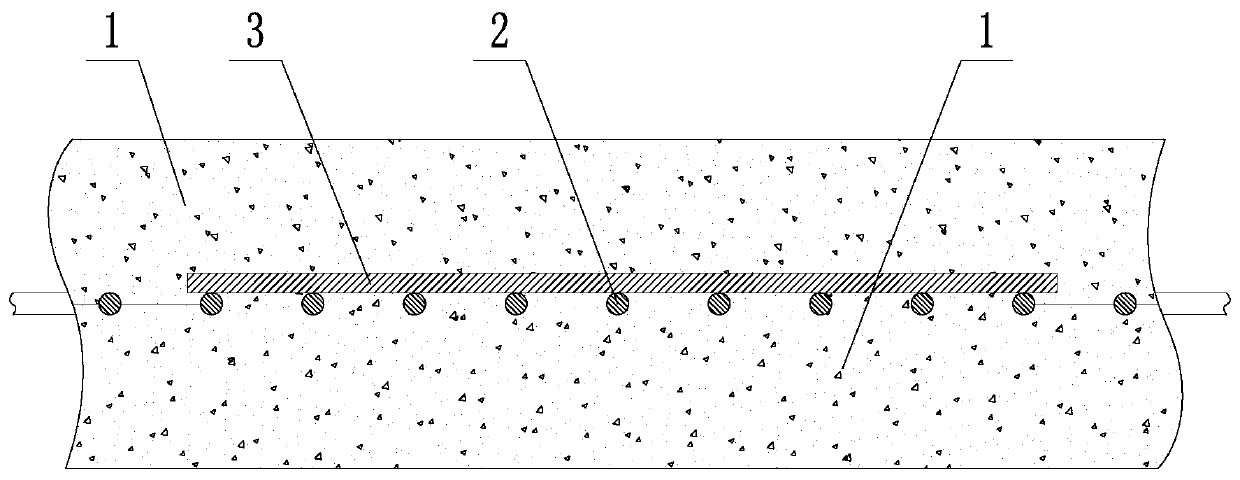

[0023] like figure 1 , 2 As shown, a high-strength demolition-free formwork includes an inorganic hardened cement fiber board 1 and a steel wire mesh sheet. The inorganic hardened cement fiber board 1 and the steel wire mesh sheet adopt a composite structure, and the steel wire mesh sheet is located in the middle of two inorganic hardened cement fiber boards 1; the steel wire The mesh sheet is composed of a steel wire mesh 2 and a steel belt 3, the steel belt 3 is flatly laid on the surface of the steel wire mesh 2, and the steel belt 3 and the steel wire mesh 2 are connected by welding.

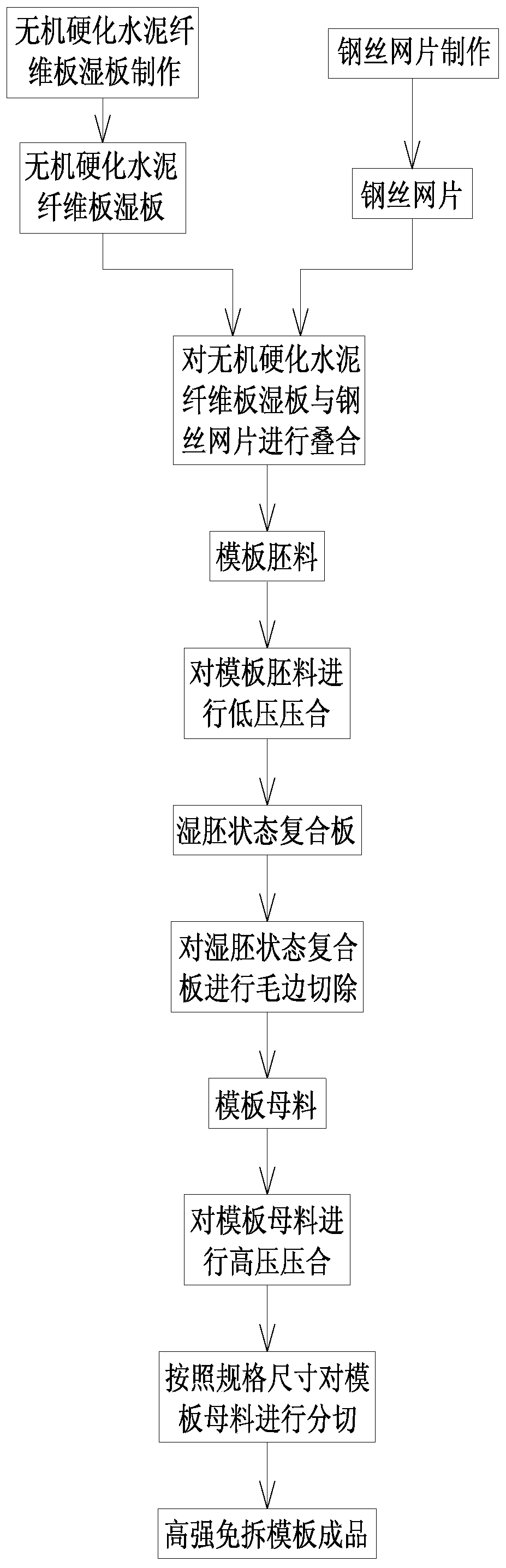

[0024] The manufacturing method of described high-strength free formwork, its flow chart is as follows image 3 shown, including the following steps:

[0025] Step 1: Select production equipment, including wet plate automatic processing equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com