Honeycomb energy absorption structure and preparation method of absorption structure

An energy absorption, honeycomb technology, applied in mechanical equipment, shock absorbers, springs/shock absorbers, etc., can solve the impact conditions that cannot adapt to changes in direction, reduce the energy absorption capacity per unit mass, and increase the production process. , to simplify the industrial production process, improve the energy absorption capacity, and improve the stiffness of the unit cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

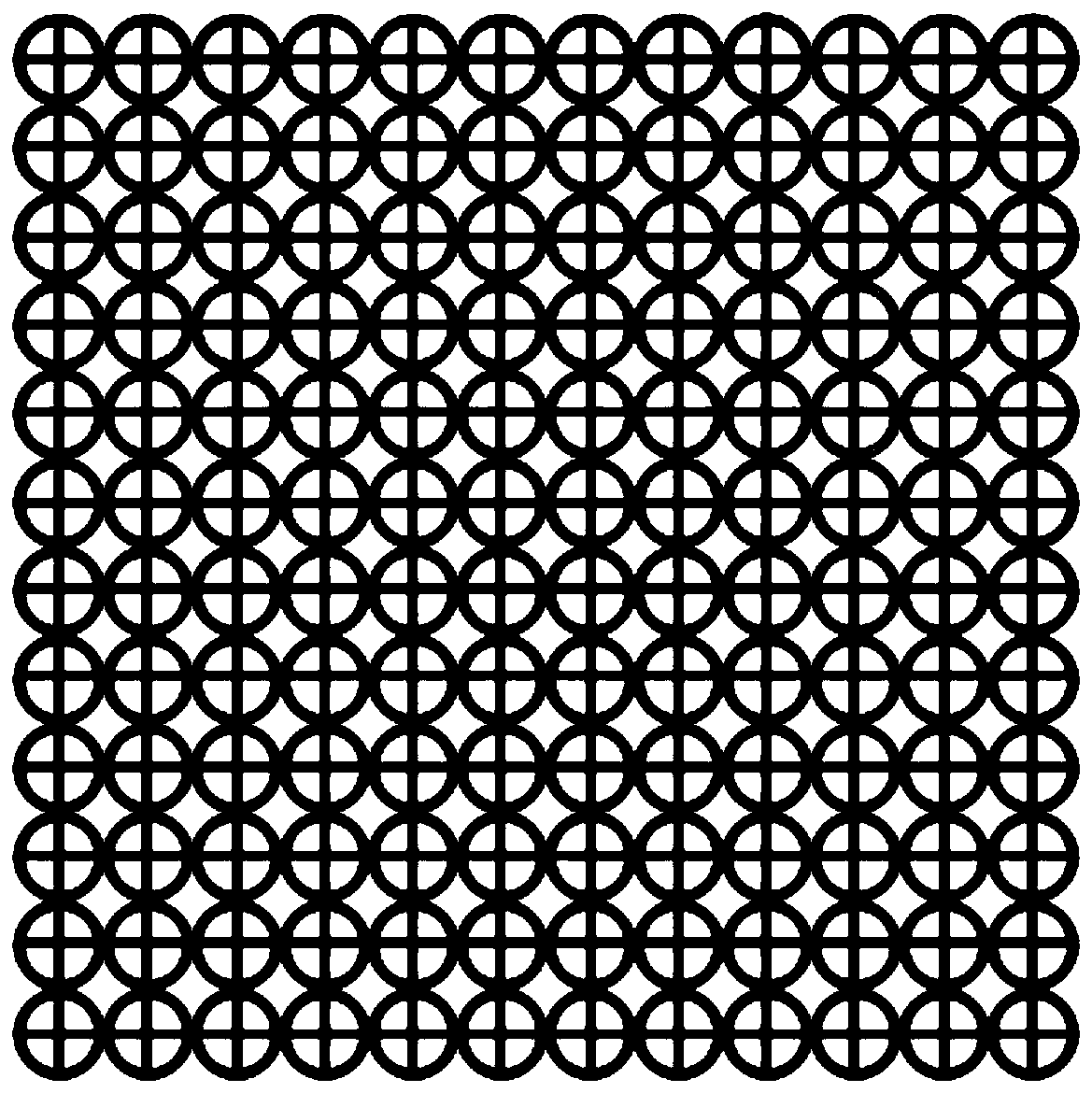

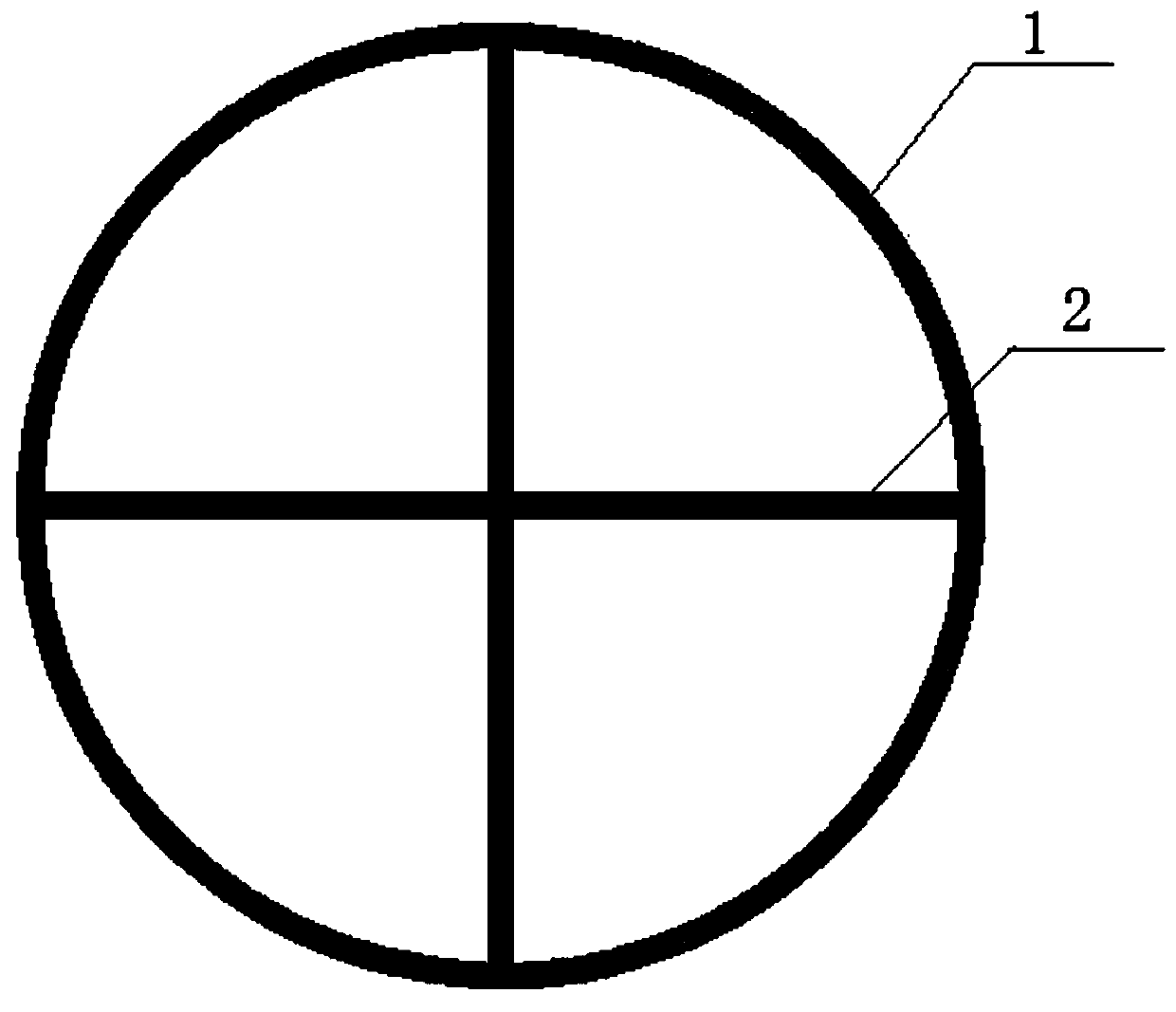

[0024] Specific implementation mode one: combine Figure 1-Figure 4 and Figure 6 Describe this embodiment, a honeycomb energy absorbing structure described in this embodiment, which includes a plurality of energy-absorbing components, each energy-absorbing component includes a circular body 1 and a 'cross' cross plate 2; a 'cross' cross plate 2 is fixedly installed on the inner wall of the torus 1, and multiple energy-absorbing components are arranged side by side in parallel to form a honeycomb energy absorption structure, and any two adjacent torus 1 are fixedly connected.

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the honeycomb energy absorption structure described in this embodiment, the ring body 1 and the 'cross' cross plate 2 are made of metal materials, and other methods are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, the honeycomb energy absorbing structure described in this embodiment, the length of the annular body 1 along the axial direction is equal to the length of the cross plate 2 along the longitudinal direction. Other methods are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com