A Method for Studying the Heat Transfer Characteristics of Melting Pool by Using the Moving Particle Finite Volume Method

A technology of melting pool and volumetric method, which is applied in the field of researching the heat transfer characteristics of high Rayleigh number melting pools by using the moving particle finite volume method, and can solve problems such as large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

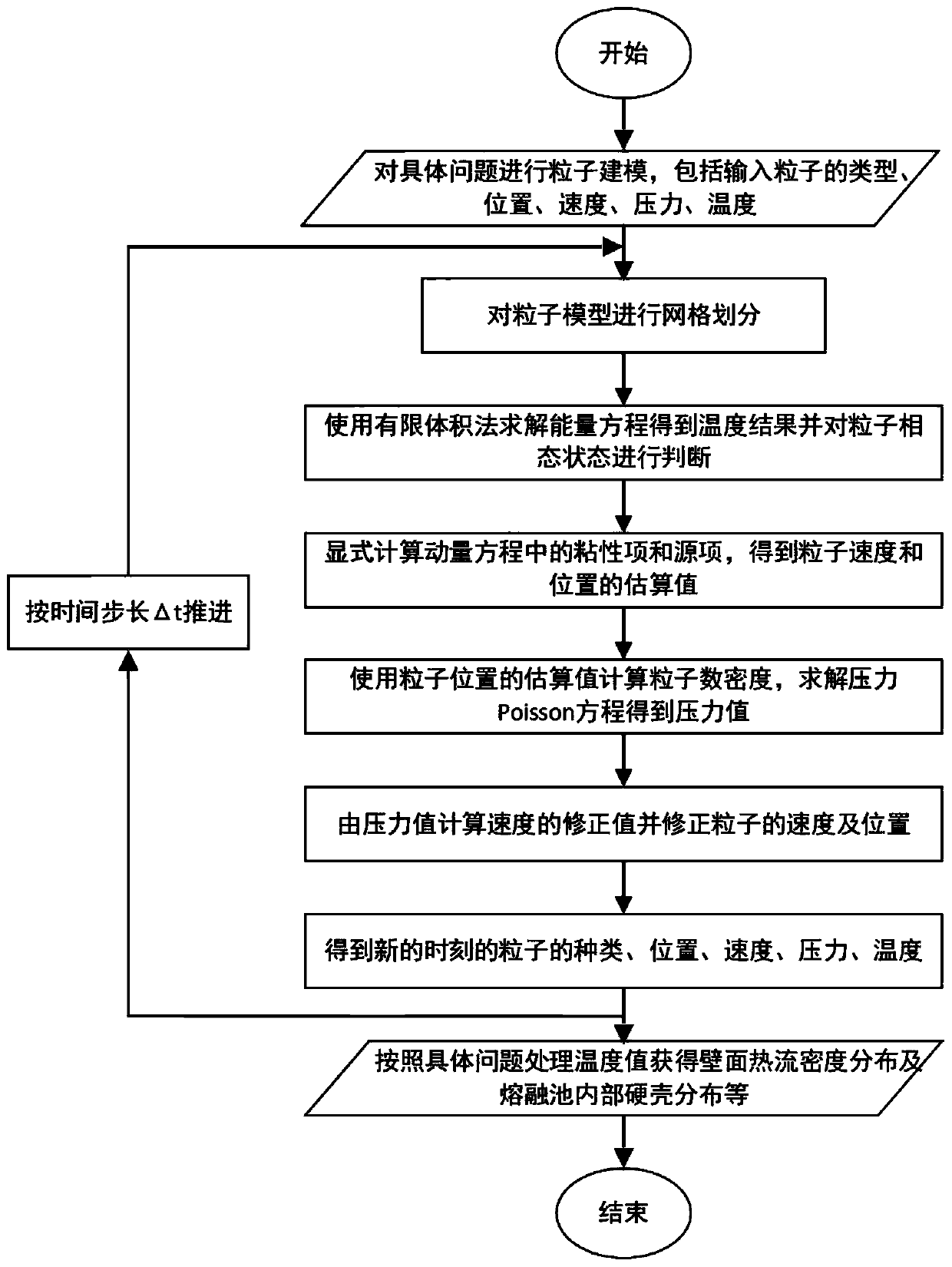

[0144] The present invention is a method for studying the heat transfer characteristics of a high Rayleigh number melting pool by using the moving particle finite volume method, such as figure 1 As shown, the steps are as follows:

[0145] Step 1: According to the research problem, particle modeling is carried out on the high Rayleigh number melting pool. Different types of particles represent different substances, and each particle has its corresponding mass, density, melting enthalpy and other information according to the substance represented, as For convenience of description, if a particle i is used to represent a certain particle, its mass, density, and melting enthalpy are marked as m i , ρ i , Set the initial arrangement of the particles, including the position, velocity, pressure and temperature of the particles, and the corresponding marks are r i , u i ,p i and T i , the distance between two adjacent particles when the particles are initially arranged is deno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com