Robust predictive control method for stirring reaction tank

A technology of stirring reaction and predictive control, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of unsatisfactory, single, fixed feedback rate of control quantity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

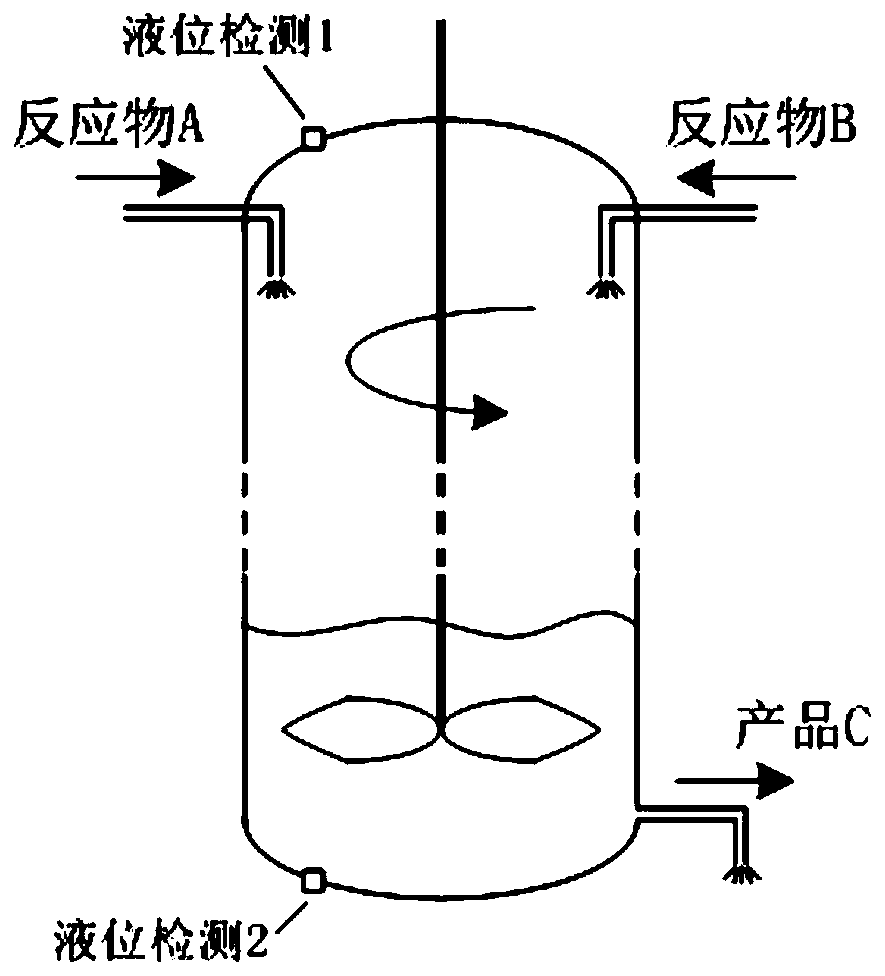

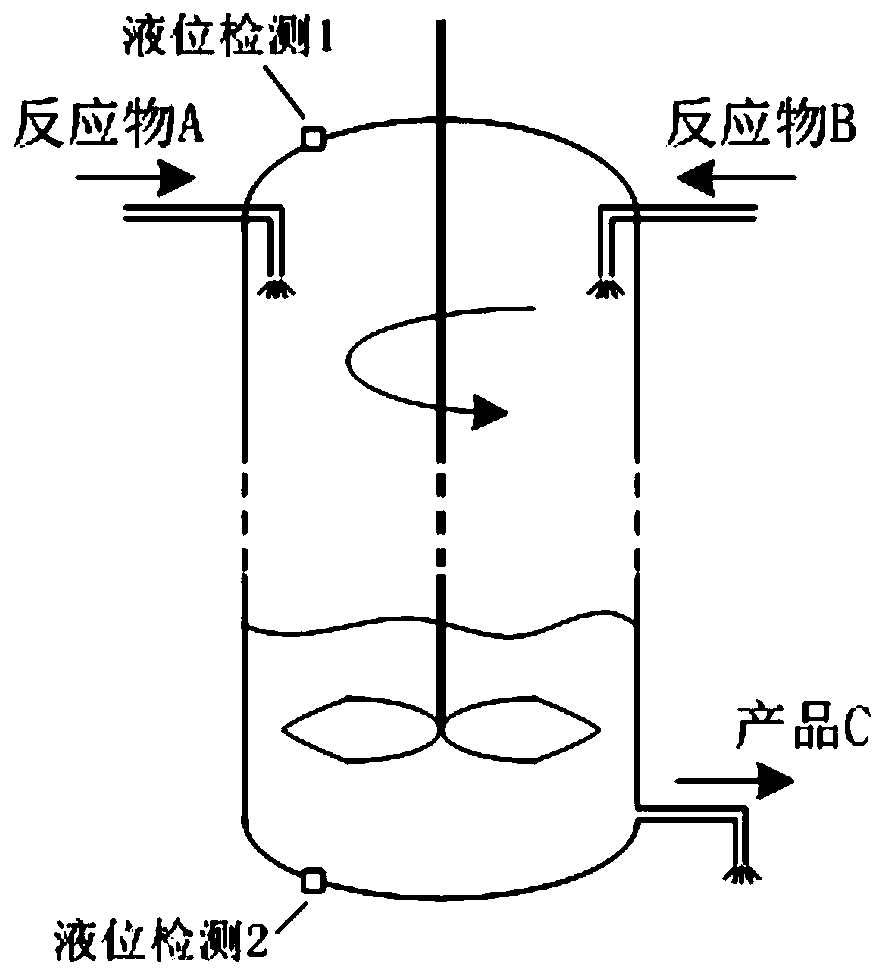

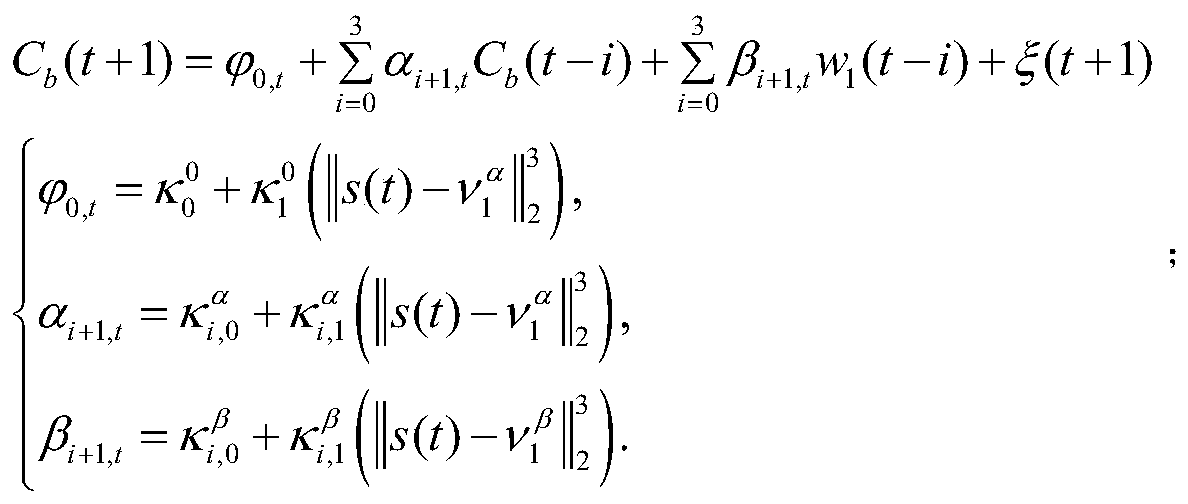

[0045] The stirred reaction tank structure that the present invention aims at is as figure 1 shown. In this embodiment, the concentration is 24.9mol / L, and the flow rate is w 1 (t) Reactant A (unit is dm / min) and reactant B with a concentration of 0.1mol / L and a flow rate of 0.1dm / min flow into the upper end of the reaction tank, and the concentration is obtained after the reaction tank is fully stirred. b (t) product C (unit is mol / L); the upper end of the reaction tank is equipped with a liquid level too high alarm sensor 1 and a liquid level too low alarm sensor 2. In this specific example, we adjust the input flow w of the reactant A 1 (t), to reach the concentration C of the control product C b (t) The purpose of following the setpoint. The specific embodiment of the present invention comprises the following steps: Step S1: collect respectively figure 1 The historical 2500 data of the input flow rate of the input reactant A and the concentration of the output product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com