Metal-air battery metal electrode material and its preparation method and application

A metal-air battery, metal electrode technology, applied in the field of electrochemical energy, can solve the problems of unsatisfactory electrochemical performance, passivation, self-corrosion and the like of metal-air battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

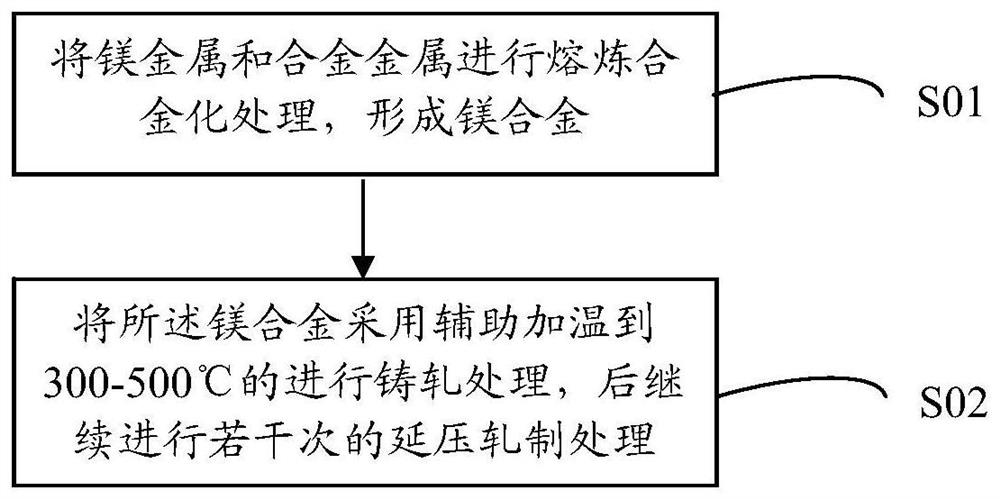

[0027] On the other hand, the embodiment of the present invention also provides the preparation method of the above-mentioned metal-air battery metal electrode material. The technical process of the preparation method of the metal-air battery metal electrode material is as follows: figure 1 shown, which includes the following steps:

[0028] S01: Smelting and alloying magnesium metal and alloy metal to form magnesium alloy;

[0029] S02: Casting and rolling the magnesium alloy by auxiliary heating to 300-500° C., and then continuing to perform several times of calendering and rolling.

[0030] Wherein, the smelting and alloying treatment in step S01 may be to melt magnesium metal and alloy metal according to the temperature and conditions for preparing magnesium alloys to form magnesium alloys.

[0031] The alloy metal in the step S01 is as described above, and may include at least one metal among aluminum, zinc, lithium, zinc, indium, gallium, and manganese. In addition, i...

Embodiment 1

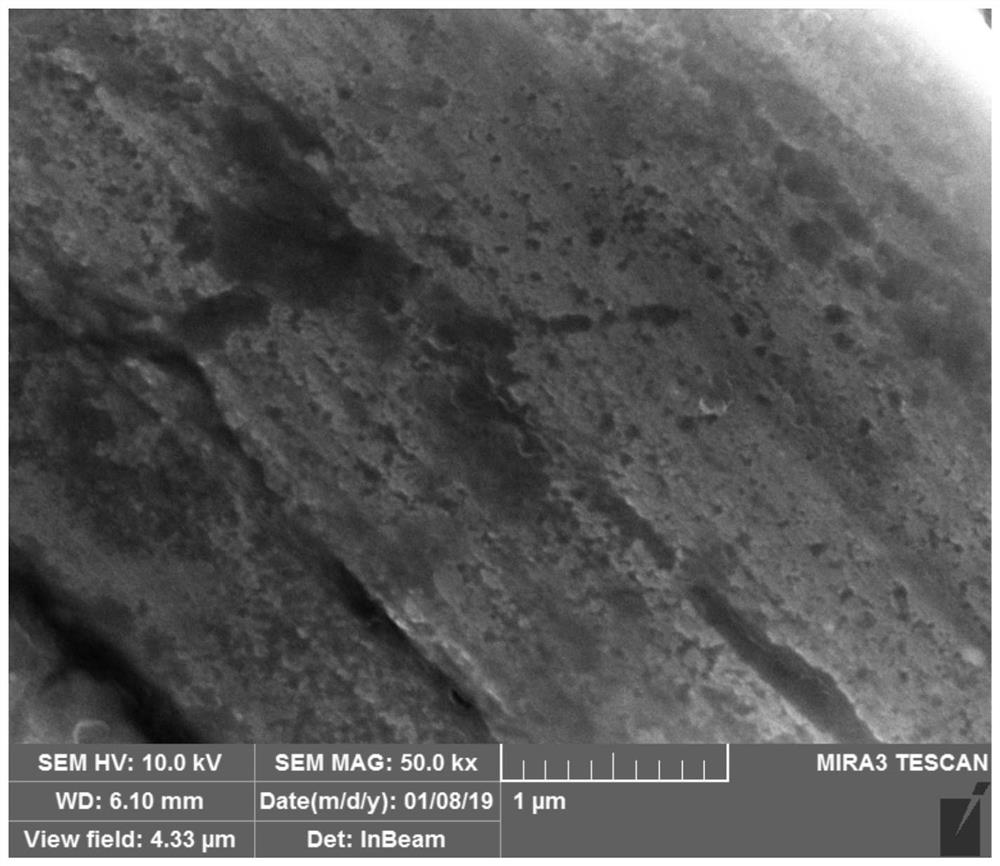

[0038] This embodiment provides a metal electrode material for a metal-air battery and a preparation method thereof. The metal electrode material of the metal-air battery is a magnesium alloy with a porous and loose structure, and it is a magnesium alloy containing 96% of Mg, 3% of Al, 0.8% of Zn, and 0.2% of Mn.

[0039] The method for preparing a metal electrode material for a metal-air battery comprises the following steps:

[0040] S11. Preparation of magnesium alloy:

[0041] After cleaning the surface of raw materials, Mg metal, Al metal, Zn metal and Mn metal are mixed and smelted and alloyed to obtain a magnesium alloy with 96% Mg, 3% Al, 0.8% Zn, and 0.2% Mn ;

[0042] S12. Carrying out cast-rolling treatment and rolling-rolling treatment to magnesium alloy:

[0043] The magnesium alloy is subjected to casting and rolling treatment with auxiliary heating to 400°C, and then continues to be rolled for several times, so that the magnesium alloy can meet the relevant p...

Embodiment 2

[0045] This embodiment provides a metal electrode material for a metal-air battery and a preparation method thereof. The metal electrode material of the metal-air battery is a magnesium alloy with a porous and loose structure, and it is a magnesium alloy containing 93% of Mg, 4% of aluminum, 1% of gallium, 1.5% of indium and 0.5% of manganese.

[0046] The method for preparing a metal electrode material for a metal-air battery comprises the following steps:

[0047] S11. Preparation of magnesium alloy:

[0048] After cleaning the surface of the raw materials, magnesium metal, aluminum metal, gallium metal, indium metal, and manganese metal are mixed and smelted and alloyed to obtain 93% magnesium, 4% aluminum, 1% gallium, and 1.5% indium , Magnesium alloy with 0.5% manganese;

[0049] S12. Carrying out cast-rolling treatment and rolling-rolling treatment to magnesium alloy:

[0050] The magnesium alloy is subjected to casting and rolling treatment with auxiliary heating to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com