Crystallizer cooling water control system and method

A control system and cooling water technology, applied in the field of metallurgical continuous casting molds, can solve the problems of inability to accurately control mold cooling water, unsatisfactory temperature stabilization effect, and large device footprint, so as to facilitate maintenance, ensure heat flow, The effect of improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

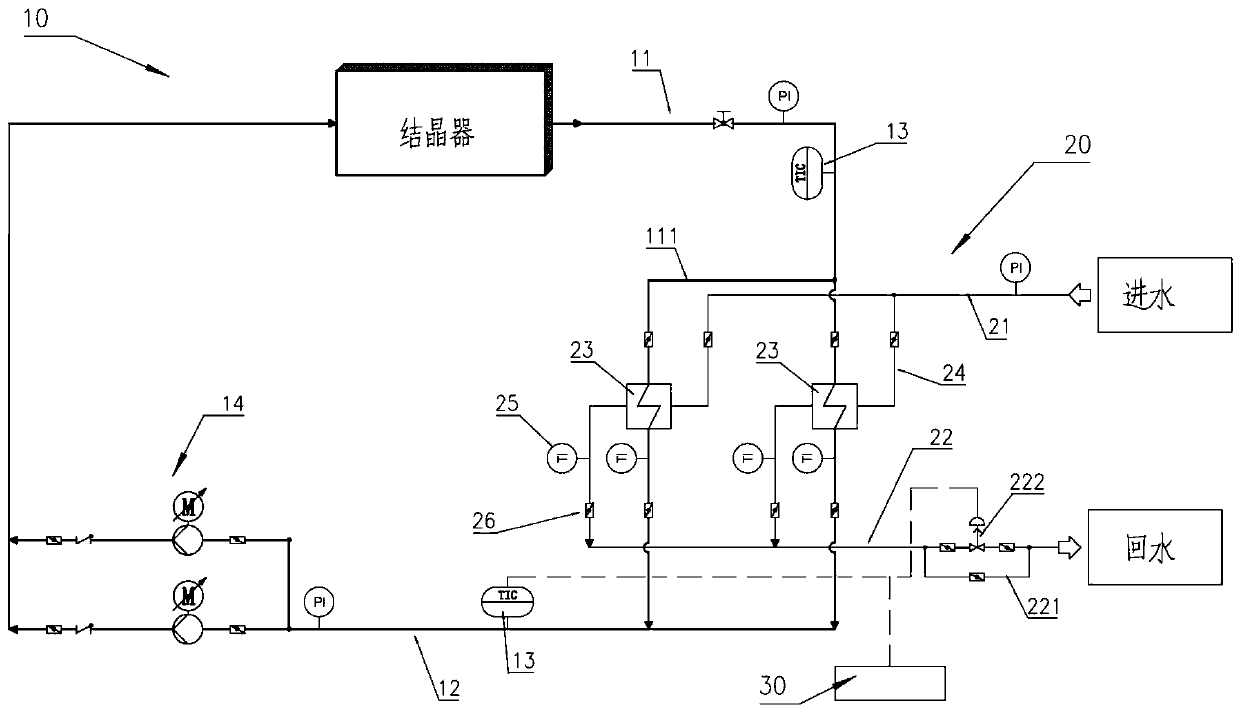

[0028] Such as figure 1 As shown, the present invention provides a crystallizer cooling water control system, including: a closed-loop circulation pipeline 10 , a heat exchange cooling pipeline 20 , and a controller 30 . Wherein, the crystallizer, the return water pipeline 11 , and the water inlet pipeline 12 are sequentially connected to form a cooling water closed circuit circulation pipeline 10 . The return water pipeline 11 is connected with a heat exchanger 23, and the inlet and outlet of the refrigerant of the heat exchanger 23 are respectively connected with the water inlet main pipe 21 and the return water main pipe 22 through the pipe 24 to form a heat exchange cooling pipe 20, so that the heat exchange cold water flows from the water inlet main pipe. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com