Continuous casting mold fluxes for medium-high carbon steel and alloy steel

A continuous casting mold flux, medium and high carbon technology, applied in the field of continuous casting mold flux, can solve the problems of slow solidification, low liquidus temperature, easy to produce surface cracks, etc., and achieve the effect of moderate viscosity bulk density and low bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example specifically illustrates the situation of using the invented continuous casting mold flux to produce high carbon alloy tool steel SKS51. The chemical composition of SKS51 produced in this embodiment (by weight, %): C 0.81, Si 0.20, Mn 0.30, P 0.15, S 0.005, Cr: 0.30, Ni: 1.5, and the rest are Fe and unavoidable residual impurities.

[0027] The mold powder composition (by weight, %) described in this embodiment is: SiO 2 30.0, CaO 29.0, MgO 4.0, Al 2 o 3 4. Fe 2 o 3 0, MnO 2 1.0, Na 2O 12.0, F9.5, C 9.8, the rest is water and / or unavoidable impurities. The physical and chemical performance indicators of the mold flux are as follows: basicity 0.97, viscosity 1.05 (1300°C) poise, melting temperature 1015°C, and bulk density 0.7Kg / L.

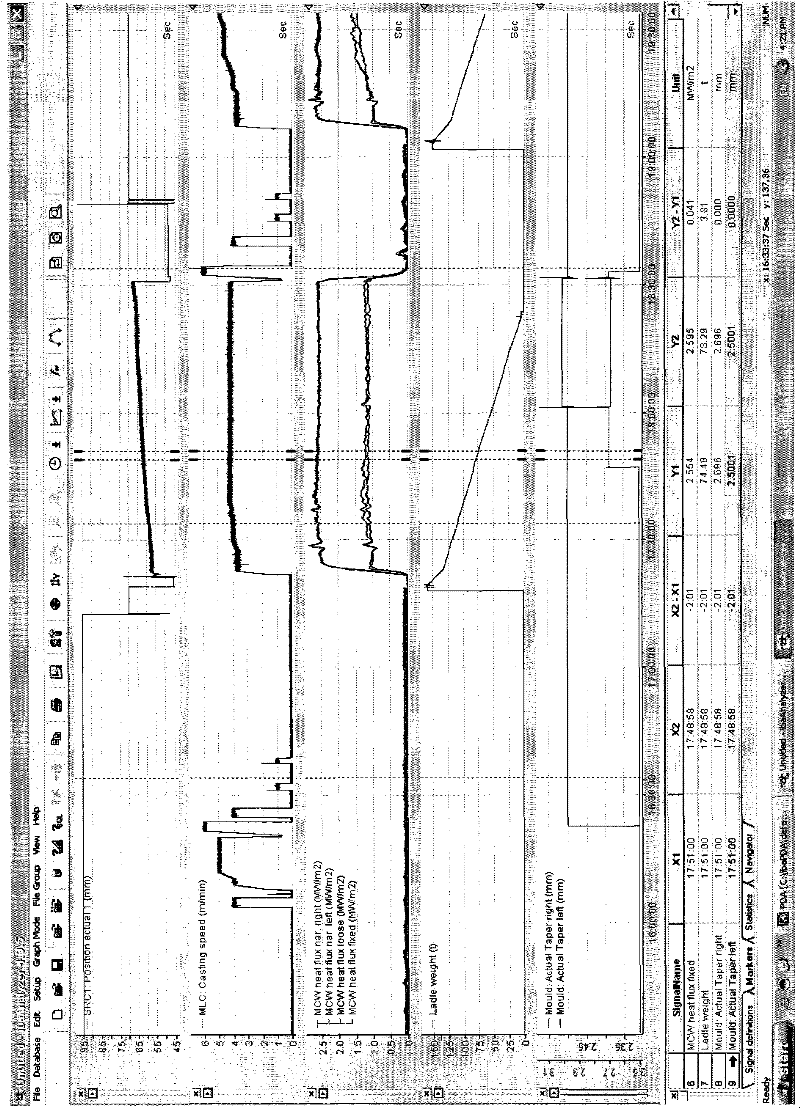

[0028] The entire pouring process is stable, and no bonded steel breakout occurs; the casting speed is stably controlled at 4.0-4.5m / min; The time-sharing pouring curve of the internal behavior of the crystallizer in ...

Embodiment 2

[0031] This example illustrates the production of high carbon alloy tool steel 8CrV2 using the invented continuous casting mold flux. The chemical composition (by weight, %) of described 8CrV2 molten steel: C 0.84, Si 0.38, Mn 0.55, P 0.020, S 0.005, Cr 0.50, V 0.18, and the rest are Fe and unavoidable impurities.

[0032] The mold powder composition (by weight, %) described in this embodiment is: SiO 2 29.0, CaO 24.0, MgO 6.0, Al 2 o 3 4.5, Fe 2 o 3 1.2, MnO 2 0.5, Na 2 O 13.0, F 12, C 7.1, LiO 2 0.8, the rest is water and / or unavoidable impurities. The physical and chemical performance indicators of the mold flux are as follows: basicity 0.83, viscosity 0.95 (1300°C) poise, melting temperature 968°C, and bulk density 0.65Kg / L.

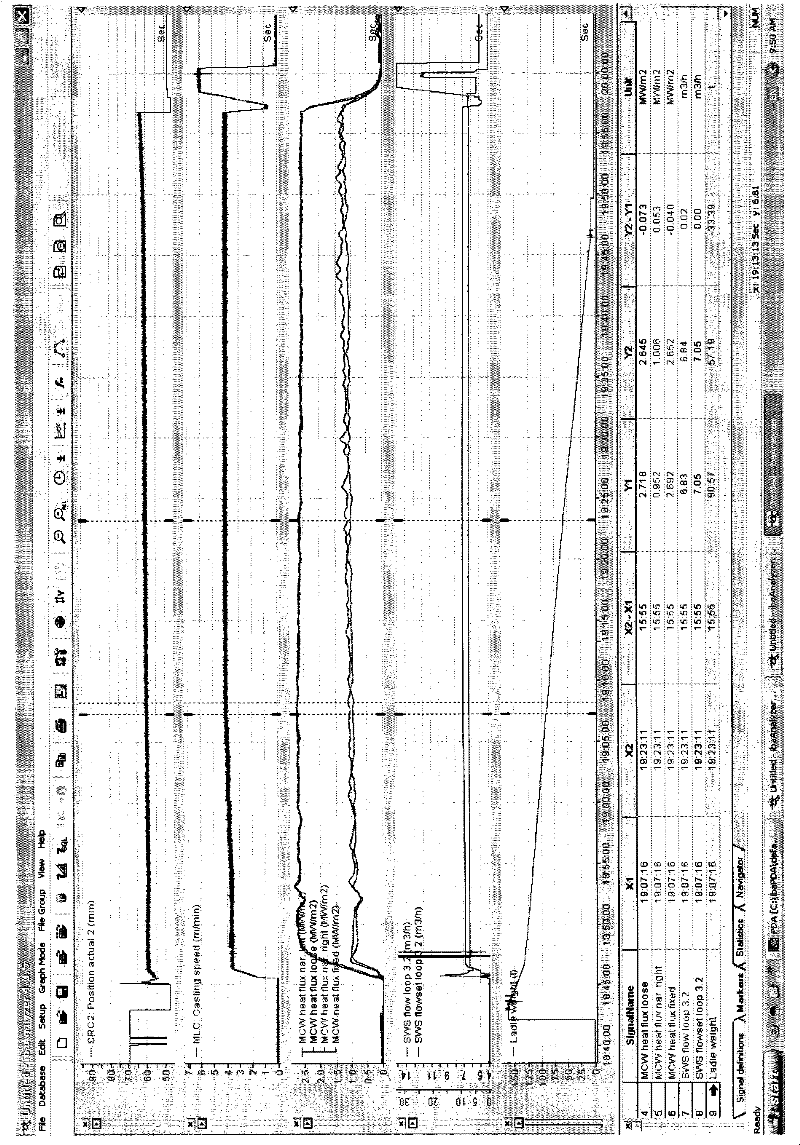

[0033] The entire pouring process is stable, and no bonded steel breakout occurs; the casting speed is stably controlled at 4.0-4.3m / min; The time-sharing pouring curve of the internal behavior of the crystallizer in the continuous cast...

Embodiment 3

[0036] This example specifically illustrates the situation of using the invented continuous casting mold flux to produce alloy structural steel 30CrMo. The chemical composition of the 30CrMo produced (by weight, %): C 0.26, Si 0.30, Mn 0.60, P 0.015, S 0.003, Cr 0.950, Mo 0.19, and the rest are Fe and unavoidable residual impurities.

[0037] The mold powder composition (by weight, %) described in this embodiment is: SiO 2 24.0, CaO 24.5, MgO 6.0, Al 2 o 3 4.5, Fe 2 o 3 1.3, MnO 2 1.0, Na 2 O 13.0, F 12, C 9.5, K 2 O 1.5, the rest is water and / or unavoidable impurities. The physical and chemical performance indicators of the mold flux are as follows: basicity 1.02, viscosity 0.90 (1300°C) poise, melting temperature 958°C, and bulk density 0.6Kg / L.

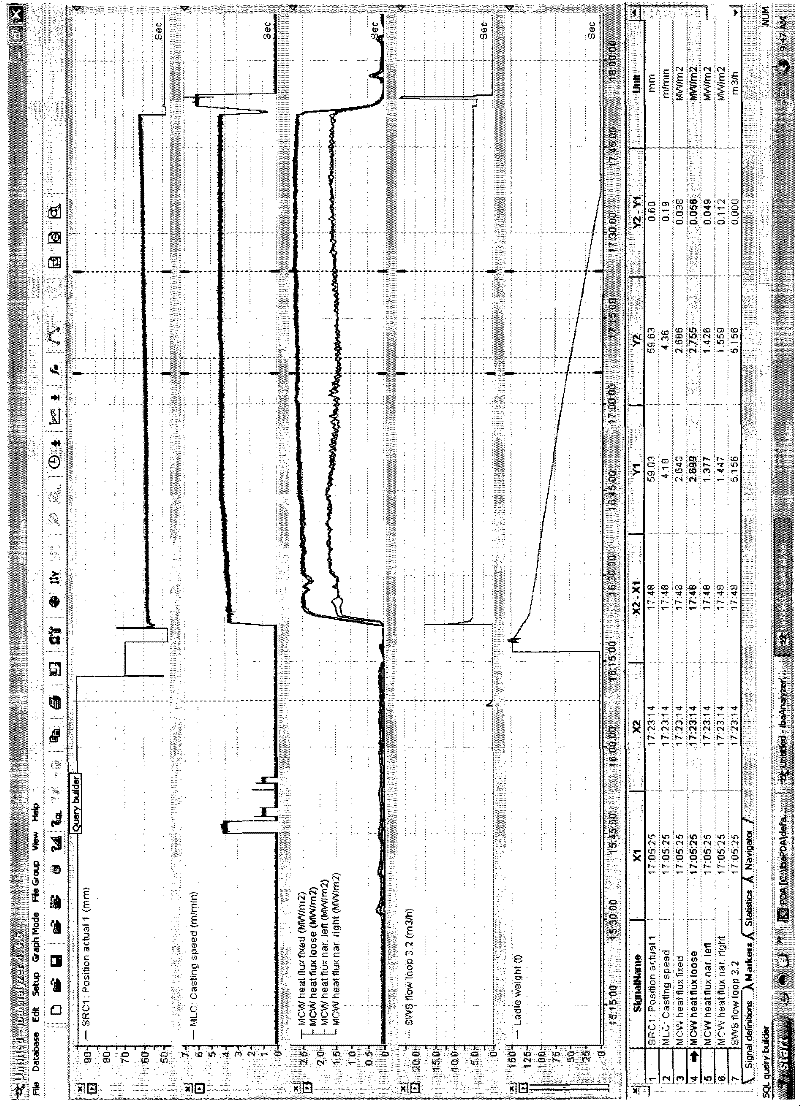

[0038] The entire pouring process is stable, and no bonded steel breakout occurs; the casting speed is stably controlled at 4.0-4.3m / min; The time-sharing pouring curve of the internal behavior of the crystallizer in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com