Measuring device for thermal conductivity of rock under high temperature and high pressure conditions

A high-temperature, high-pressure, thermal conductivity technology, which is applied to the measurement device of rock thermal conductivity and the field of heterogeneous materials, can solve the problem of inability to accurately describe the anisotropy of rock thermal conductivity, and the application of triaxial confining pressure is complicated, difficult to control, and impossible to measure Rock thermal conductivity and other issues, to achieve the effect of high degree of equipment automation, good sealing, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1, rock thermal conductivity measuring instrument under complex conditions.

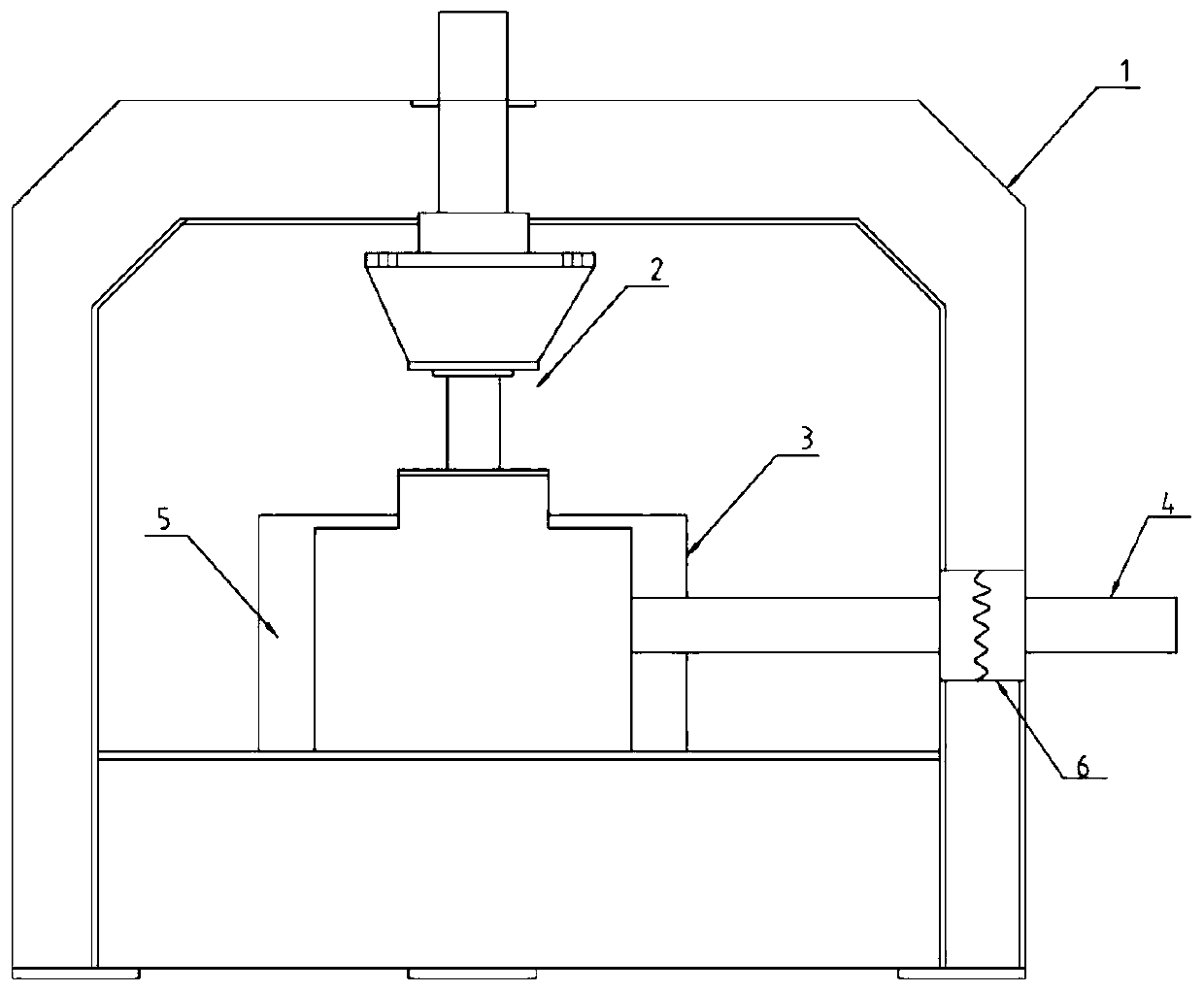

[0039] See figure 1 As shown, it mainly includes a frame assembly 1 , a normal force applying device 2 , a thermal insulation frame 3 of an experimental chamber, a confining pressure applying device 4 , an experimental chamber 5 and a confining pressure sensor 6 .

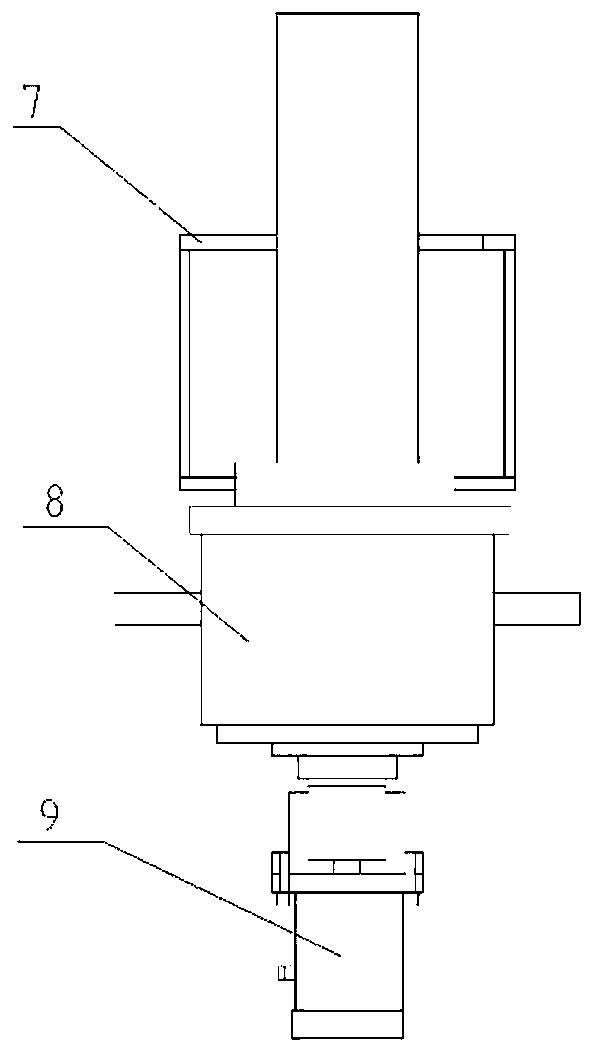

[0040] See figure 2 As shown, the normal force applying device mainly includes a servo motor 7, a lift 8, a load sensor and a displacement sensor 9, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com