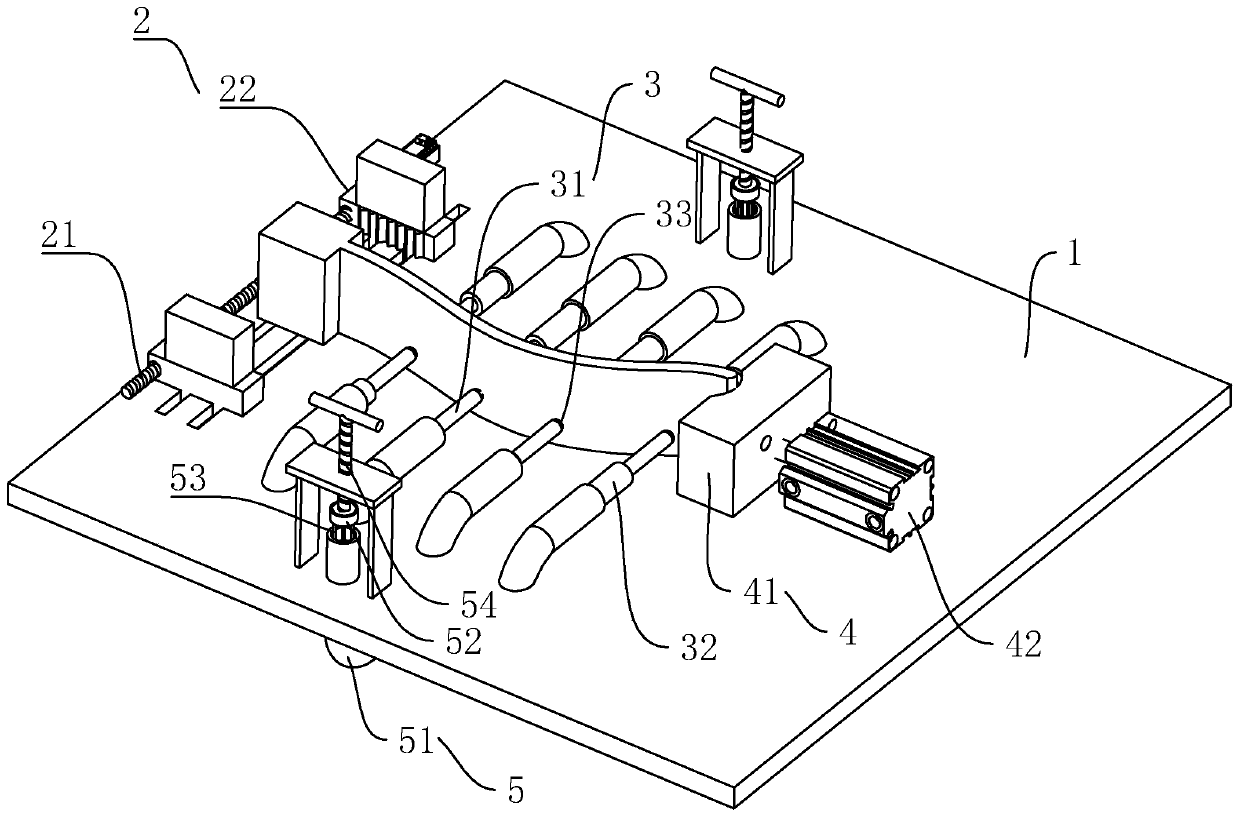

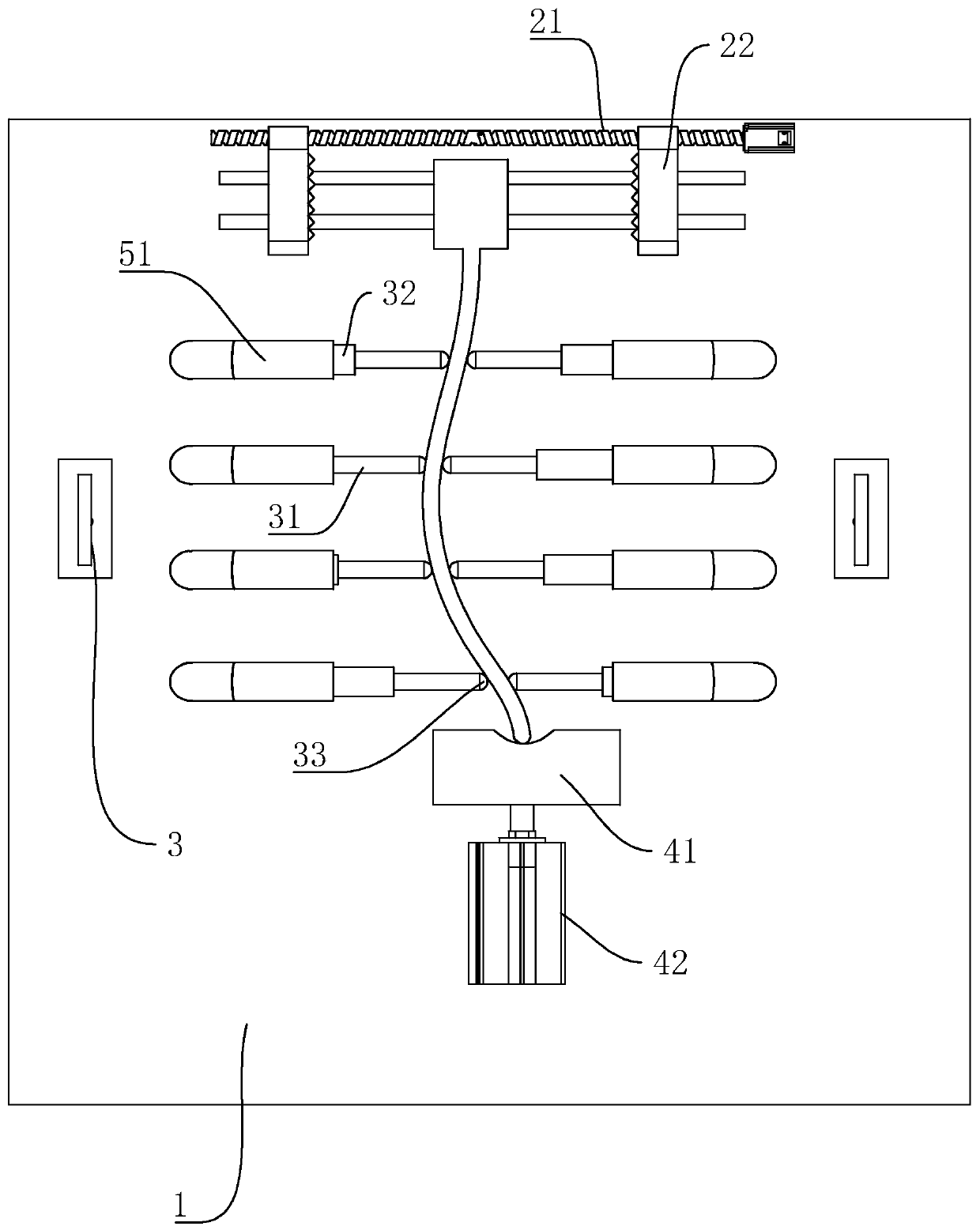

Steam turbine blade machining platform

A steam turbine blade and processing table technology, applied in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve problems such as complicated use, avoid frequent replacement, good overall positioning and support effect, and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

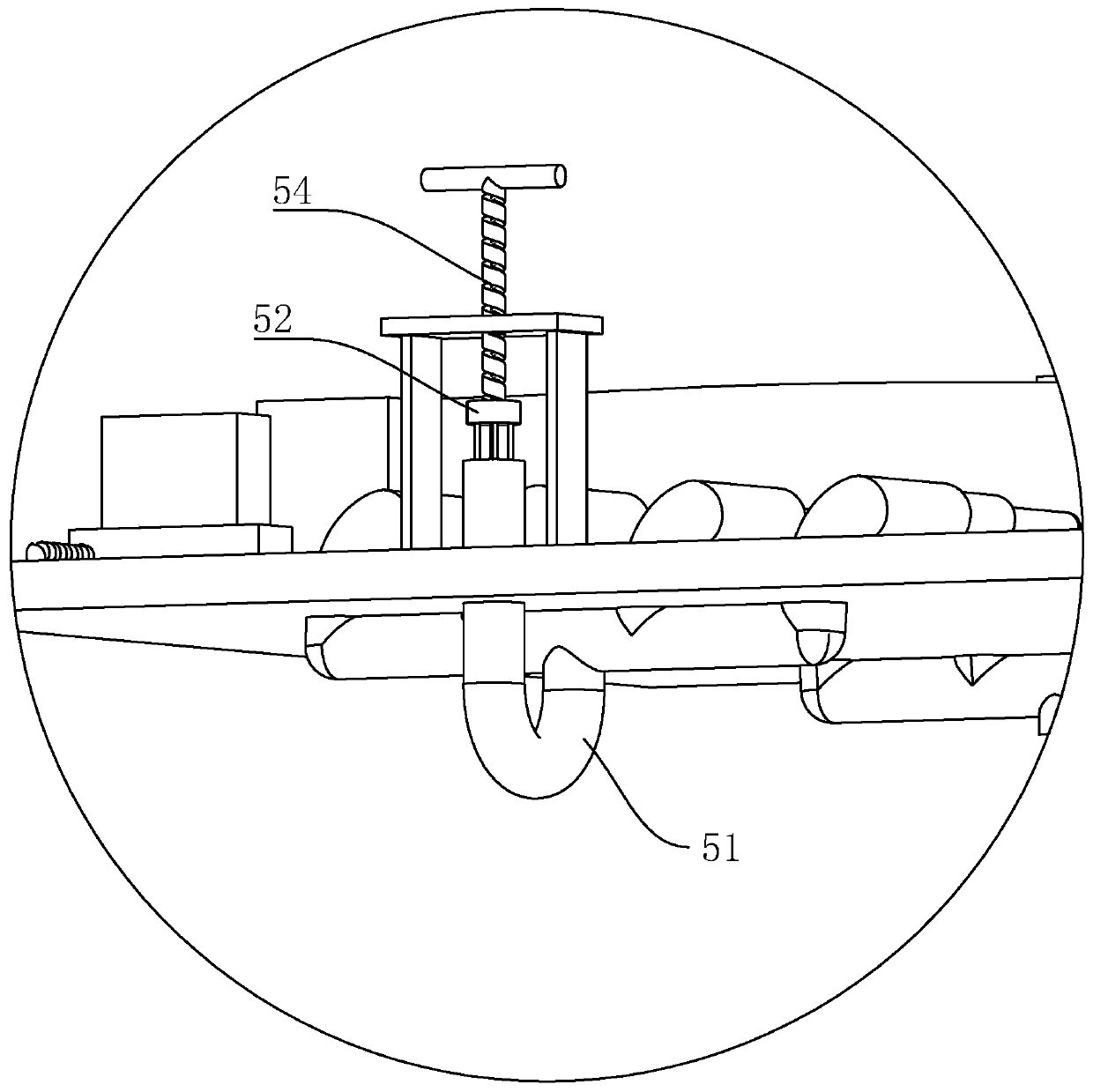

[0039] A kind of steam turbine blade processing table provided in this embodiment, such as Figure 4 As shown, the difference from Embodiment 1 is that the locking part 6 includes a pressurizing piston 52 slidably connected in the pressurizing tube, and a pushing rack 55 is fixed on the pressurizing piston 52, and the pushing rack 55 is compatible with the working The table 1 is slidingly connected, and a push gear 56 is connected to the workbench 1 through a rotating shaft 57 in rotation, and the push gear 56 and the push rack 55 are meshed with each other.

[0040]The locking part 6 includes a locking worm 62 coaxially fixed on the rotating shaft 57 and a locking worm 61 rotatably connected to the workbench 1. The locking worm 61 and the locking worm 62 are engaged with each other, and the workbench 1 There is a servo motor 63 for driving the locking worm 61 to rotate.

[0041] When the operator needs to process the blade, the top of the blade can be clamped and fixed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com