Rubber mixing machine for rubber processing

A rubber mixing machine and rubber technology, which is applied in the field of rubber processing, can solve the problems of poor plasticization effect, rotating roller stability and surface damage of rotating rollers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

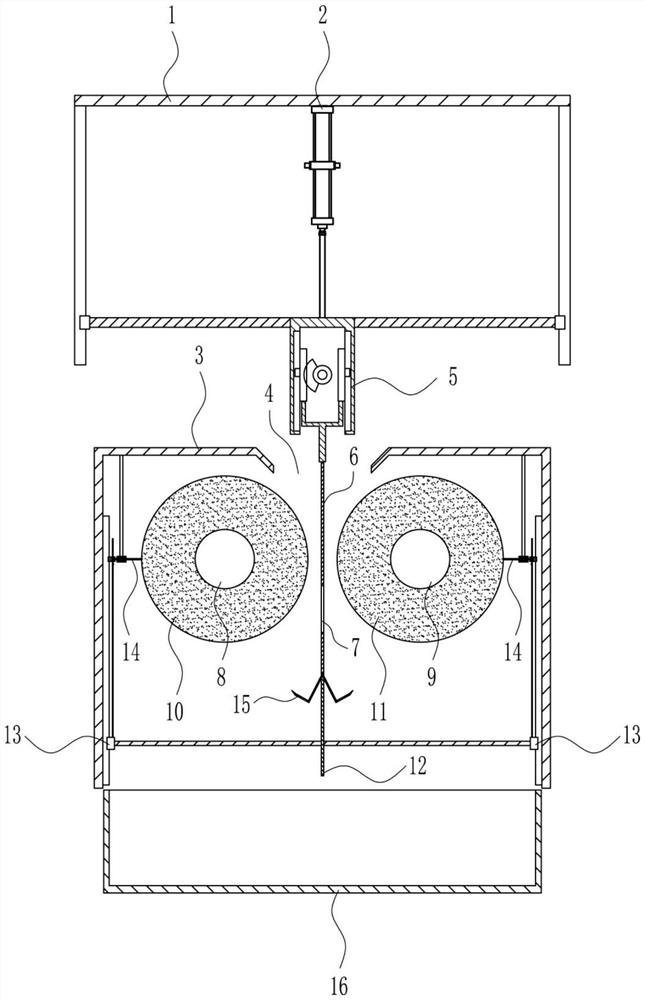

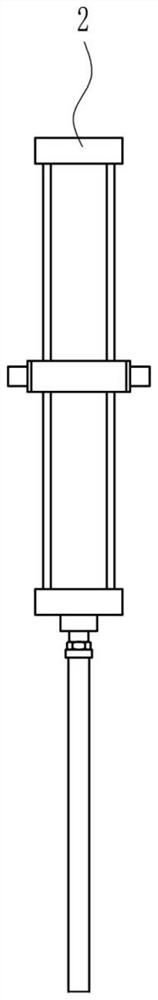

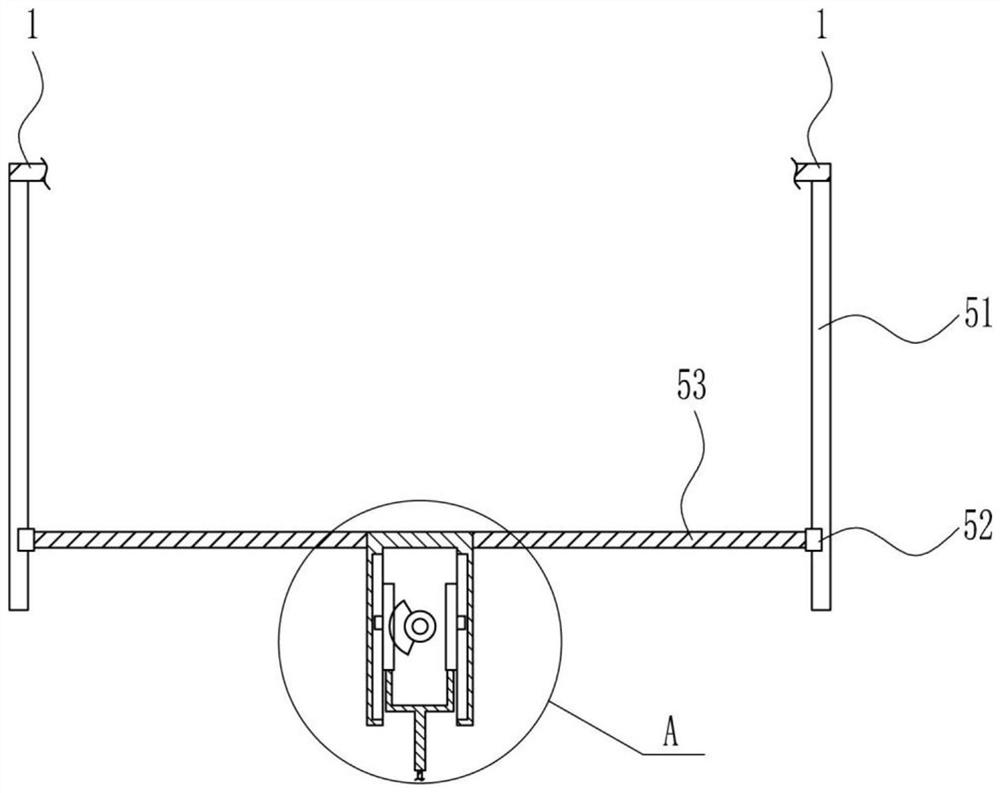

[0034] A rubber mixing machine for rubber processing, such as Figure 1-13 As shown, it includes a frame 1, a hydraulic cylinder 2, a machine body 3, a raw material plasticizing adjustment mechanism 5, a pressing plate 6, a second motor 8, a third motor 9, a first rotating roller 10, a second rotating roller 11, and a connecting plate 12. The stabilization mechanism 13, the first scraping mechanism 14, the second scraping mechanism 15 and the collection frame 16; the bottom of the frame 1 is fixedly connected with the body 3 and the hydraulic cylinder 2, and the body 3 is located below the hydraulic cylinder 2; the middle of the top of the body 3 A feed inlet 4 is provided, a second motor 8 and a third motor 9 are fixedly connected to the rear outer wall of the body 3, and the second motor 8 is positioned on the left side of the third motor 9; The first rotating roller 10 is connected, the output end of the third motor 9 is fixedly connected with the second rotating roller 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com