Car blocking part gripping system and blocking part gripping method

A technology for blocking parts and automobiles, which is applied in the direction of cleaning methods using liquids, cleaning methods using gas flow, cleaning methods and utensils, etc. It can solve the problems of poor stability of manual picking of blocking parts, the risk of occupational diseases for operators, and needle-nose pliers. To avoid problems such as short life, to avoid distortion, increase stability, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

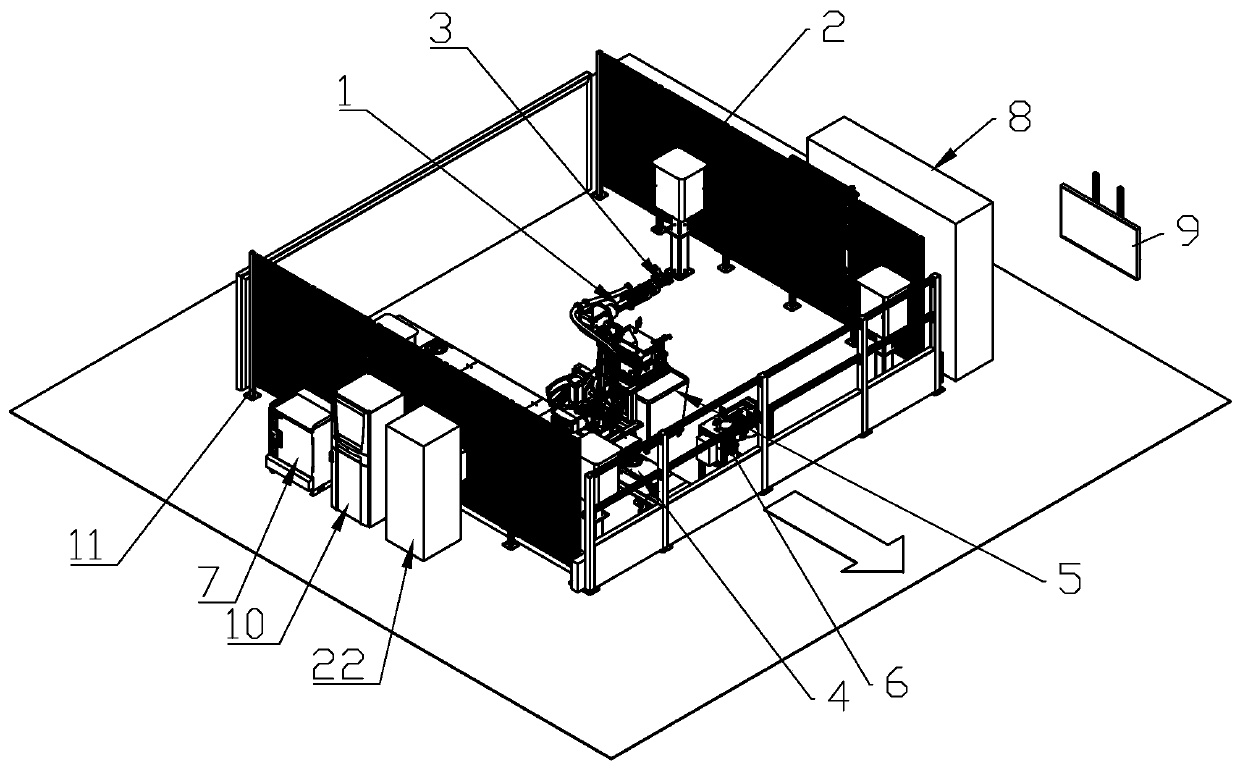

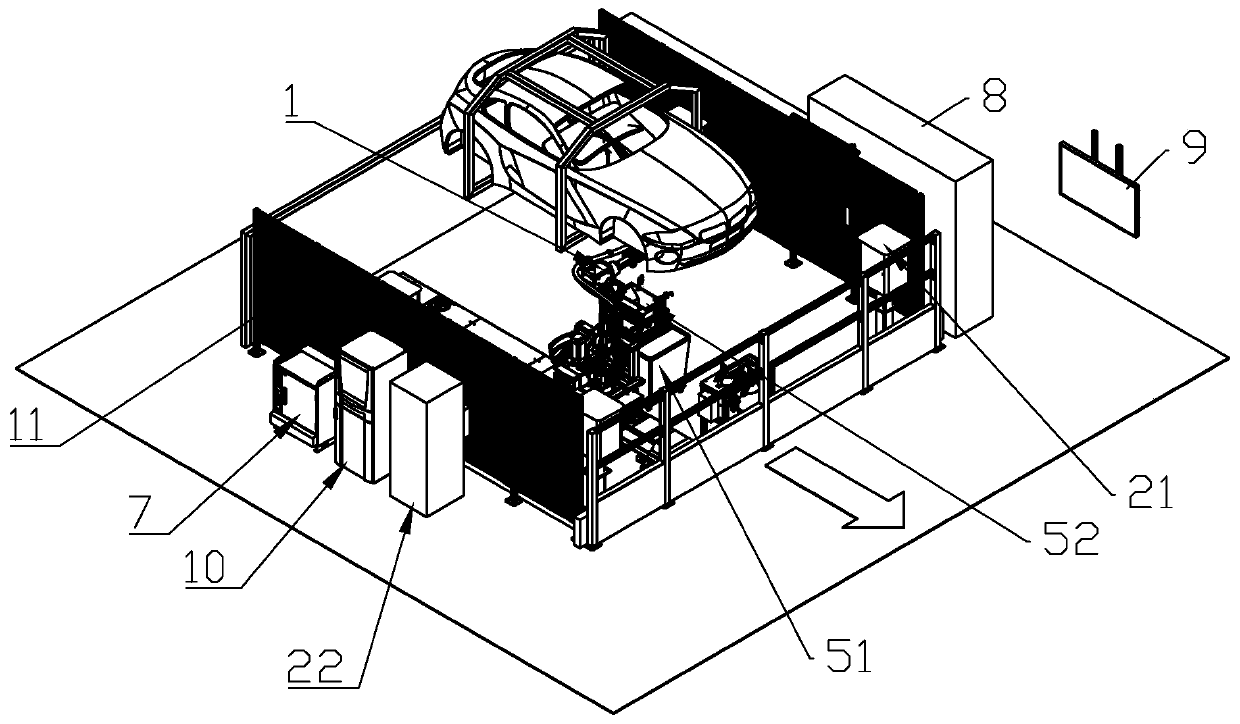

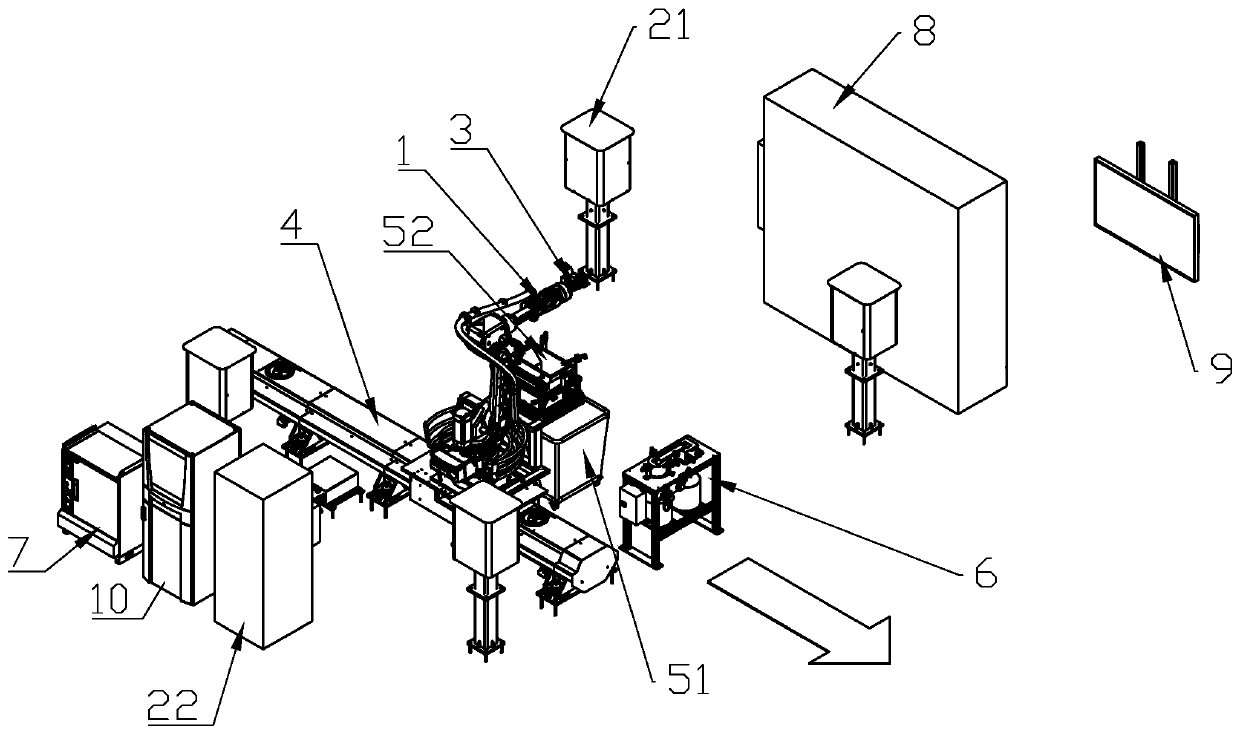

[0072] Refer to the attached Figure 1 to attached Figure 41 The automobile blocking piece grasping system and the blocking piece grasping method of the present invention will be described in detail below.

[0073] The blocking piece grasping system for automobiles of the present invention has a structure comprising a robot 1, a vehicle body positioning device 2, a blocking piece gripper 3, a robot guide rail 4, a blocking piece recovery device 5 and an ultrasonic cleaning machine 6, and the robot 1 and the blocking piece The piece gripper 3 is connected, the robot 1 is arranged on the robot guide rail 4 and moves along the robot guide rail 4, the blocking piece recovery device 5 is arranged on one side of the robot guide rail 4, and the ultrasonic cleaning machine 6 is arranged on At the end of the robot guide rail 4, the vehicle body positioning device 2 is arranged on the four corners outside the robot guide rail 4, and the robot 1 and the blocking gripper 3 are electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com