Ca/Mn co-doped (Gd, Y) AG red fluorescent powder

A red phosphor, 20at.%y3 technology, used in luminescent materials, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

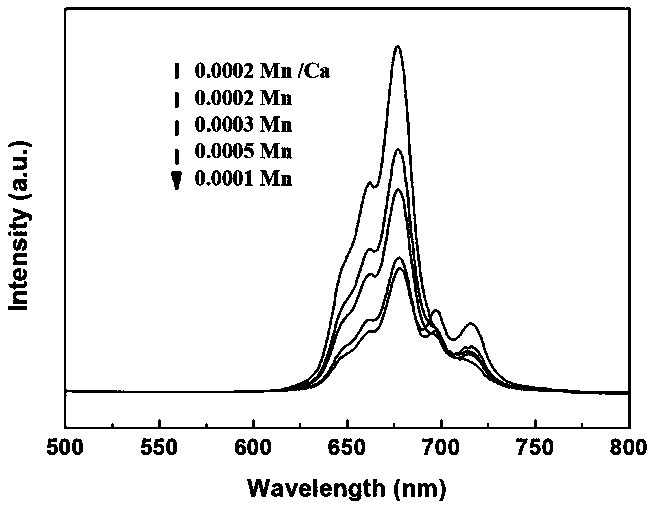

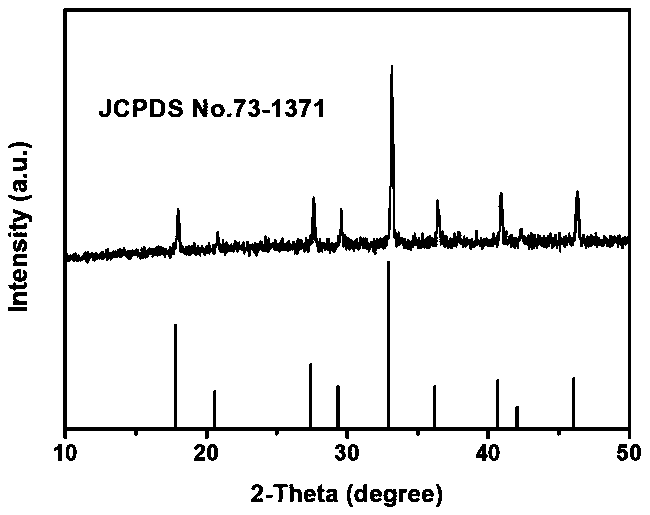

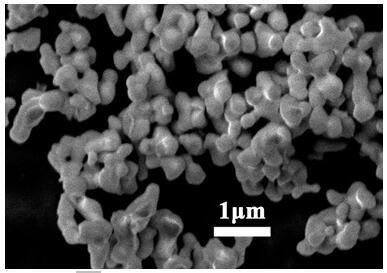

[0029] A Ca / Mn co-doped (Gd, Y)AG red fluorescent powder, the preparation method is as follows:

[0030] Raw materials used: Gd 2 o 3 (99.99%), Y 2 o 3 (99.99%), Ca(NO 3 ) 3 4H 2 O(99.0%)Al(NO 3 ) 3 9H 2 O (99.0%), MnCl 4H 2 O (99.0%), NH 4 HCO 3 (99.0%), nitric acid (HNO3 , 68%);

[0031] (1) Powdered Gd 2 o 3 and Y 2 o 3 respectively dissolved in hot nitric acid to remove excess HNO 3 Dubbed rare earth nitrate solution;

[0032] (2) Ca(NO 3 ) 3 4H 2 O, Al(NO 3 ) 3 9H 2 O and MnCl 4H 2 O is dissolved in deionized water to form Ca(NO 3 ) 3 , Al(NO 3 ) 3 and MnCl solution;

[0033] (3) Press (Gd 0.8-5x / 3 Y 0.2 Ca 5x / 3 ) 3 (Al 1-x mn x ) 5 o 12 ( x =0.0001) Stoichiometric ratio Measure the salt solution, add deionized water to make a solution with a volume of 100 mL, stir for 10 min, so that the mother salt solution is evenly mixed;

[0034] (4) Weigh an appropriate amount of NH 4 HCO 3 Dissolve in deionized water, place in a constant tem...

Embodiment 3

[0039] A Ca / Mn co-doped (Gd, Y)AG red fluorescent powder, the preparation method is as follows:

[0040] Raw materials used: Gd 2 o 3 (99.99%), Y 2 o 3 (99.99%), Ca(NO 3 ) 3 4H 2 O(99.0%)Al(NO 3 ) 3 9H 2 O (99.0%), MnCl 4H 2 O (99.0%), NH 4 HCO 3 (99.0%), nitric acid (HNO 3 , 68%);

[0041] (1) Powdered Gd 2 o 3 and Y 2 o 3 respectively dissolved in hot nitric acid to remove excess HNO 3 Dubbed rare earth nitrate solution;

[0042] (2) Ca(NO 3 ) 3 4H 2 O, Al(NO 3 ) 3 9H 2 O and MnCl 4H 2 O is dissolved in deionized water to form Ca(NO 3 ) 3 , Al(NO 3 ) 3 and MnCl solution;

[0043] (3) Press (Gd 0.8-5x / 3 Y 0.2 Ca 5x / 3 ) 3 (Al 1-x mn x ) 5 o 12 ( x =0.0003) Stoichiometric ratio Measure the salt solution, add deionized water to make a solution with a volume of 100 mL, stir for 10 min, so that the mother salt solution is evenly mixed;

[0044] (4) Weigh an appropriate amount of NH 4 HCO 3 Dissolve in deionized water, place in a constant t...

Embodiment 4

[0049] A Ca / Mn co-doped (Gd, Y)AG red fluorescent powder, the preparation method is as follows:

[0050] Raw materials used: Gd 2 o 3 (99.99%), Y 2 o 3 (99.99%), Ca(NO 3 ) 3 4H 2 O(99.0%)Al(NO 3 ) 3 9H 2 O (99.0%), MnCl 4H 2 O (99.0%), NH 4 HCO 3 (99.0%), nitric acid (HNO 3 , 68%);

[0051] (1) Powdered Gd 2 o 3 and Y 2 o 3 respectively dissolved in hot nitric acid to remove excess HNO 3 Dubbed rare earth nitrate solution;

[0052] (2) Ca(NO 3 ) 3 4H 2 O, Al(NO 3 ) 3 9H 2 O and MnCl 4H 2 O is dissolved in deionized water to form Ca(NO 3 ) 3 , Al(NO 3 ) 3 and MnCl solution;

[0053] (3) Press (Gd 0.8-5x / 3 Y 0.2 Ca 5x / 3 ) 3 (Al 1-x mn x ) 5 o 12 ( x =0.0005) Stoichiometric ratio Measure the salt solution, add deionized water to make a solution with a volume of 100 mL, stir for 10 min, and mix the mother salt solution evenly;

[0054] (4) Weigh an appropriate amount of NH 4 HCO 3 Dissolve in deionized water, place in a constant temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com