Construction method and structure of balance weight retaining wall

A construction method and retaining wall technology, which is applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of poor connection reliability between the balance platform and the wall, low construction reliability, and high construction difficulty. Achieve significant economic and environmental benefits, ensure the smoothness of the appearance, and reduce the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

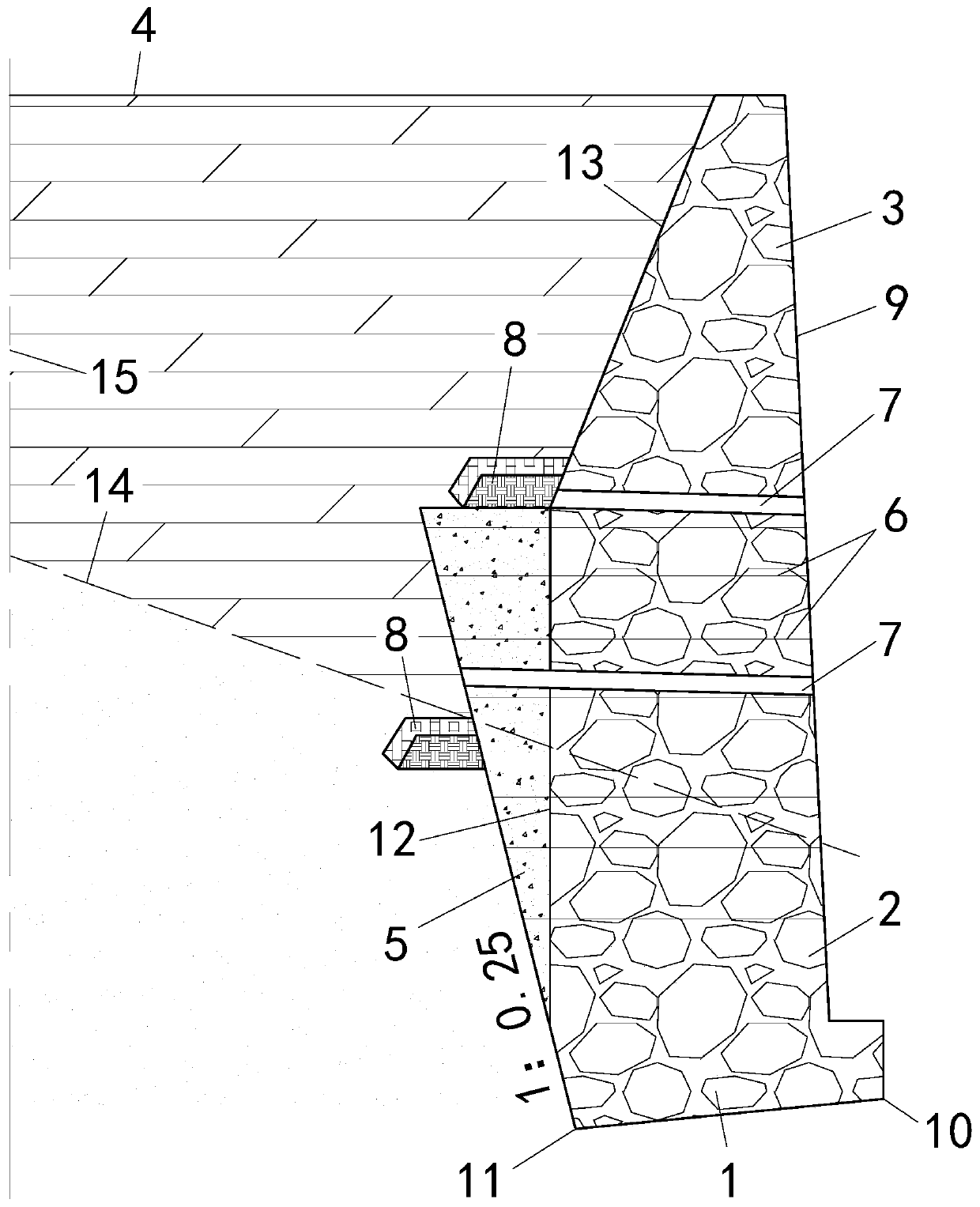

[0024] The structure of this example is as follows figure 1 shown. Including foundation 1, lower wall 2, upper wall 3, steel bar 6, drain pipe 7, reverse filter layer 8, reinforced concrete balance platform 5. During the masonry process, the lower wall 2 is provided with pre-embedded connecting steel bars 6 connecting the counterweight platform 5 , and the reinforced concrete counterweight platform 5 and the lower wall 2 form a reliable connection through the pre-embedded connecting steel bars 6 . A drain pipe 7 is arranged at the joint between the upper wall 3 and the lower wall 2. After the construction of the main structure of the retaining wall is completed, an anti-filter layer 8 is arranged at the inlet end of the drain pipe 7. The anti-filter layer 8 is divided into four layers from bottom to top. It consists of geotextile, crushed stone, gravel or stone chips and geotextile.

[0025] During the specific implementation, the main steps are as follows:

[0026] a. Make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com