Method and device for determining working range state of industrial robot

A technology for industrial robots and working ranges, which can be used in measuring devices, instruments, positioning, etc., and can solve problems such as low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

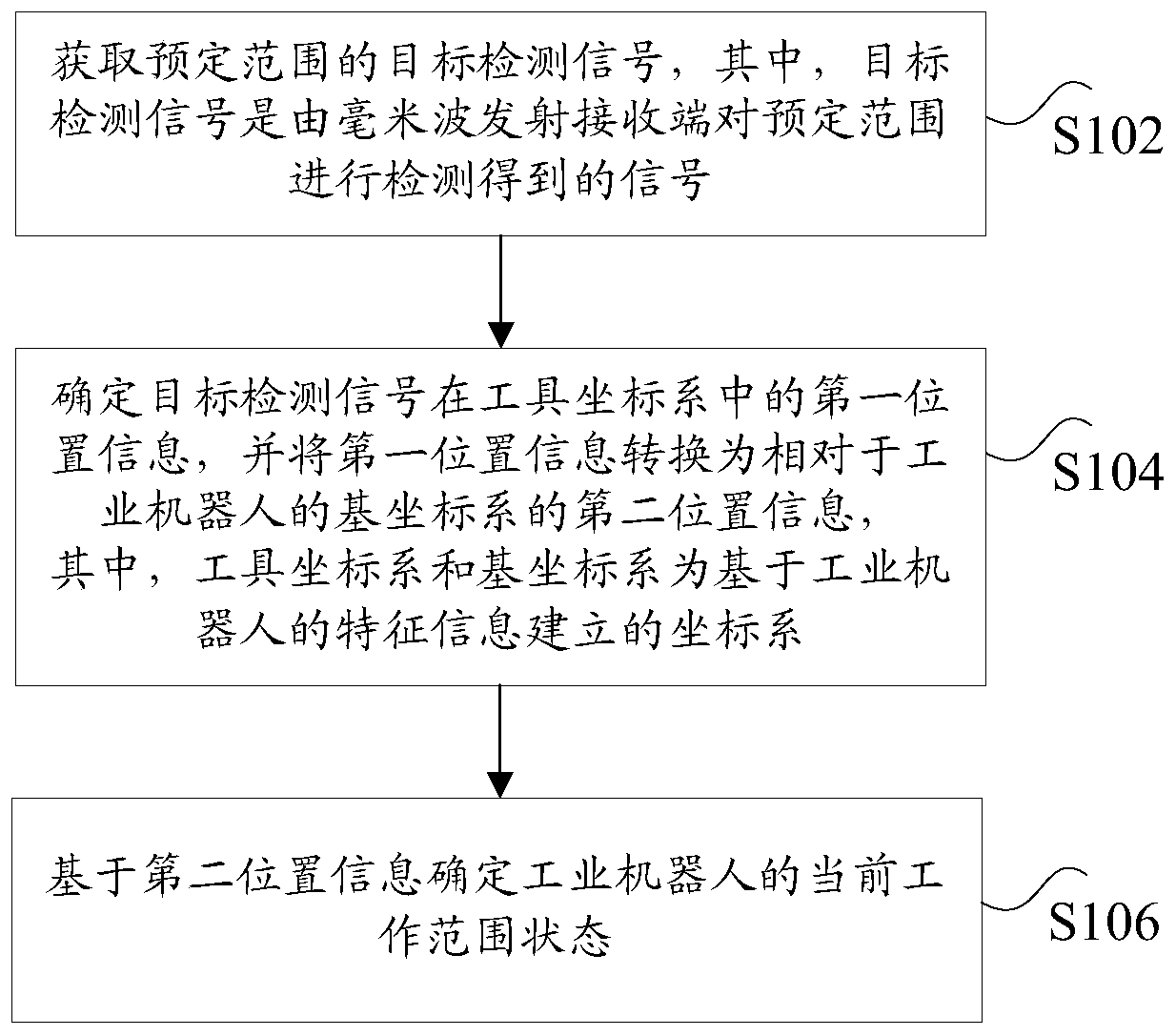

[0041] According to an embodiment of the present invention, a method embodiment of a method for determining the state of the working range of an industrial robot is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be implemented in a computer such as a set of computer-executable instructions system, and, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0042] figure 1 is a flowchart of a method for determining the working range state of an industrial robot according to an embodiment of the present invention, such as figure 1 As shown, the method for determining the working range state of the industrial robot includes the following steps:

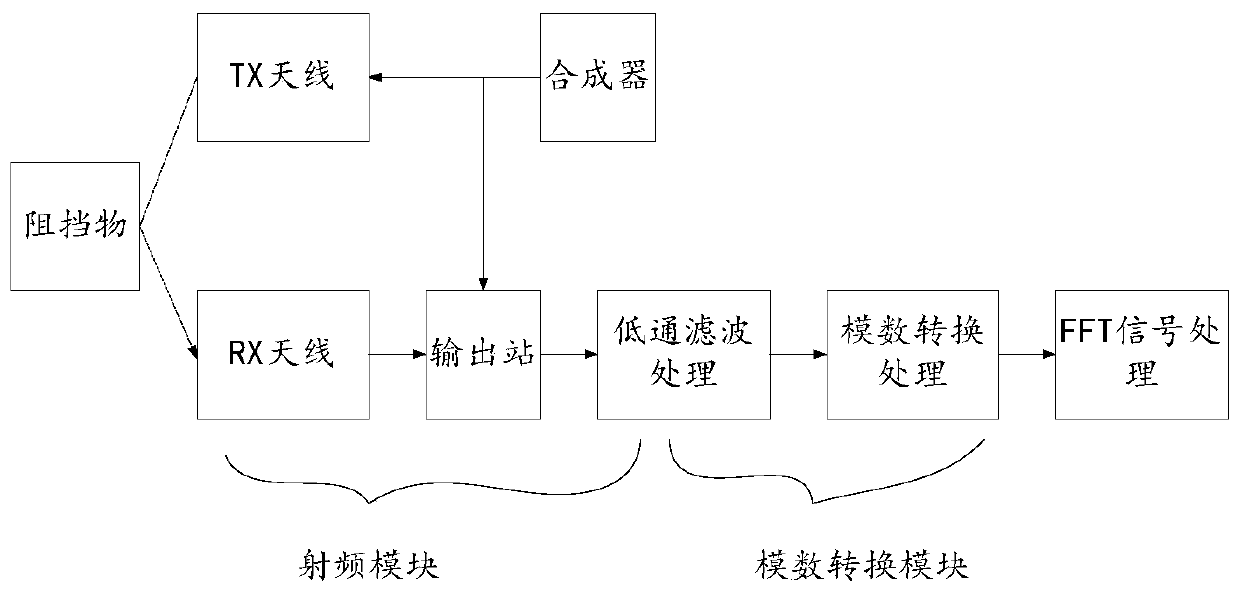

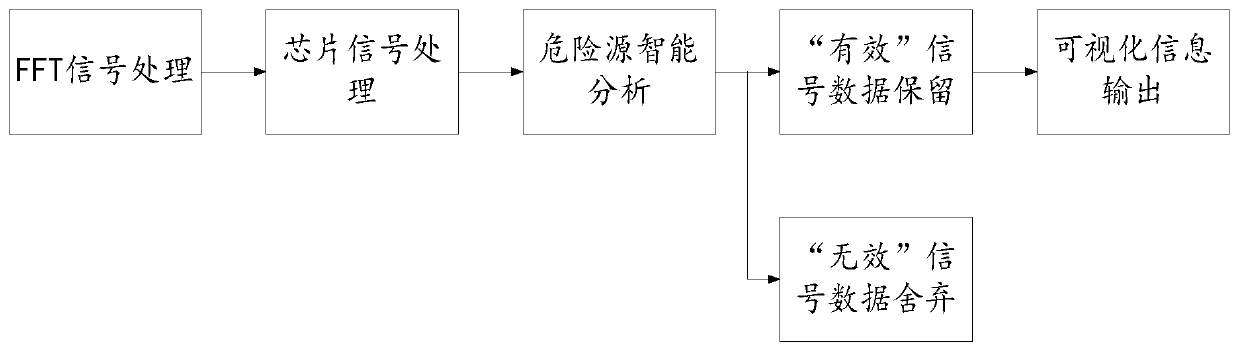

[0043] Step S102, acquiring a target detection signal within a predetermined range, wherein the target detection signal is a signal obtained by detecting a predeterm...

Embodiment 2

[0071] According to another aspect of the embodiments of the present invention, a device for determining the state of the working range of an industrial robot is also provided, Figure 5 is a schematic diagram of a device for determining the working range state of an industrial robot according to an embodiment of the present invention, such as Figure 5 As shown, the device for determining the state of the working range of the industrial robot includes: an acquisition unit 51 , a conversion unit 53 and a determination unit 55 . The device for determining the state of the working range of the industrial robot will be described in detail below.

[0072] Wherein, the acquiring unit 51 is configured to acquire a target detection signal in a predetermined range, wherein the target detection signal is a signal obtained by detecting a predetermined range by a millimeter wave transmitting and receiving end.

[0073] The conversion unit 53 is used to determine the first position infor...

Embodiment 3

[0087] According to another aspect of the embodiments of the present invention, there is also provided an industrial robot, including: any one of the devices for determining the state of the working range of the industrial robot described above. The industrial robot provided by the embodiment of the present invention can use the millimeter wave as the detection carrier to realize the purpose of detecting the working range of the industrial robot, and the millimeter wave has strong penetrability, short wavelength, and propagates at the speed of light, with high accuracy and high detection accuracy. The speed is fast, which realizes the purpose of quickly detecting the working range of industrial robots, improves the technical effect of the reliability of detecting the working range of industrial robots, and then solves the problem of detecting the working range of industrial robots in related technologies. way of low reliability technical issues.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com