Process for assembly of motor-generators

A technology for motor generators and armatures, which is used in the manufacture of motor generators, motor components, and the shape/style/structure of winding insulation, which can solve problems such as manual labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

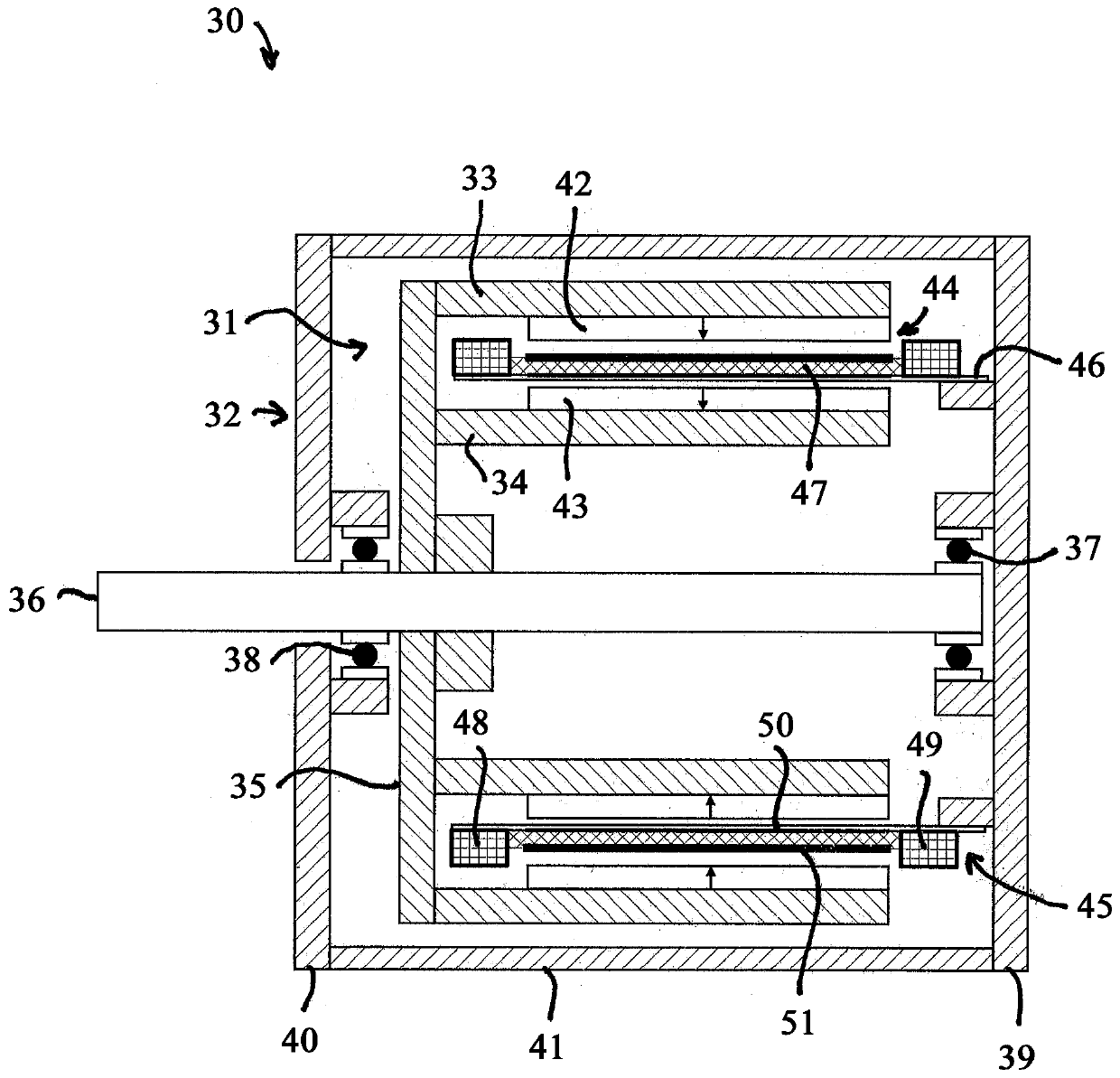

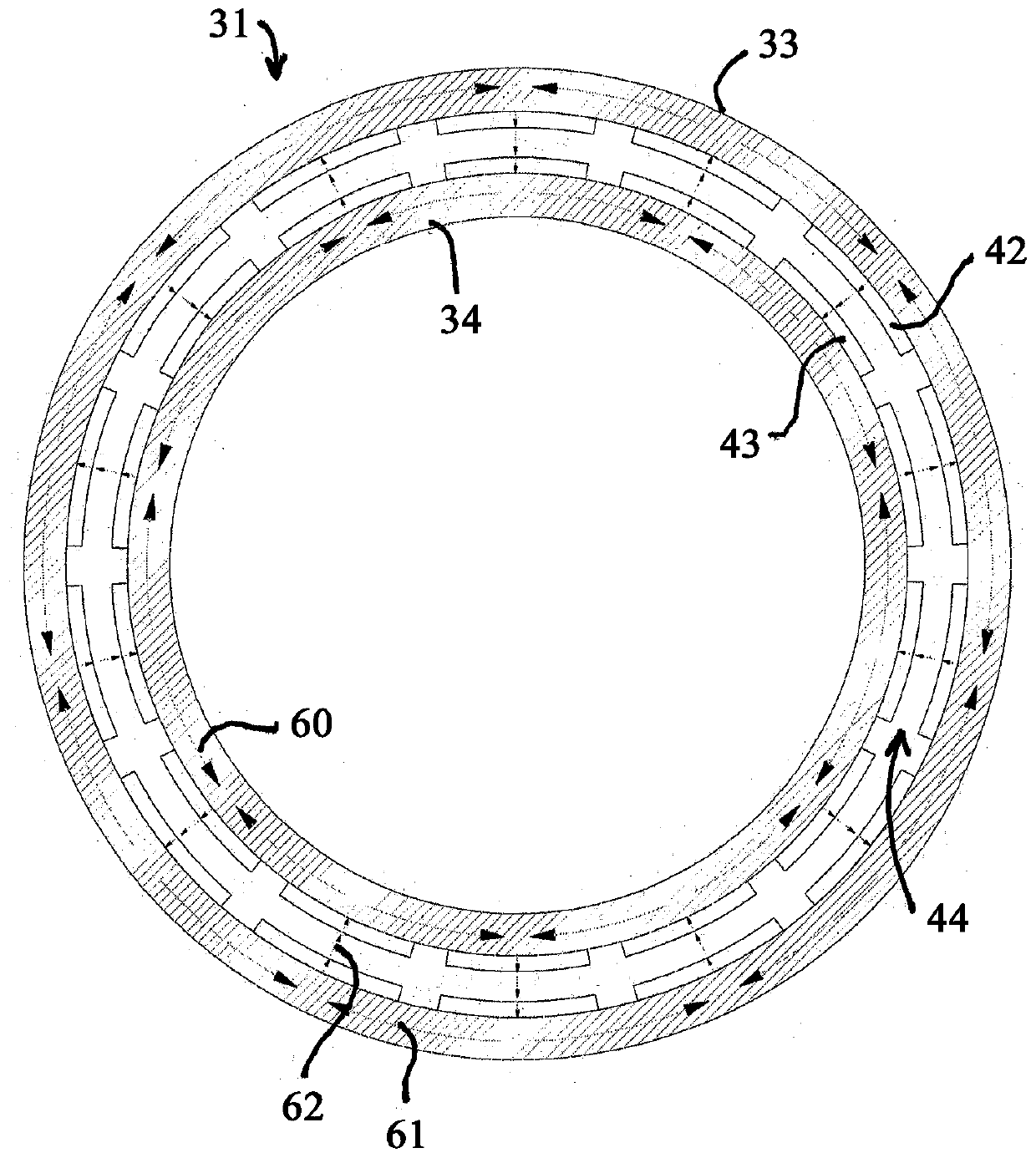

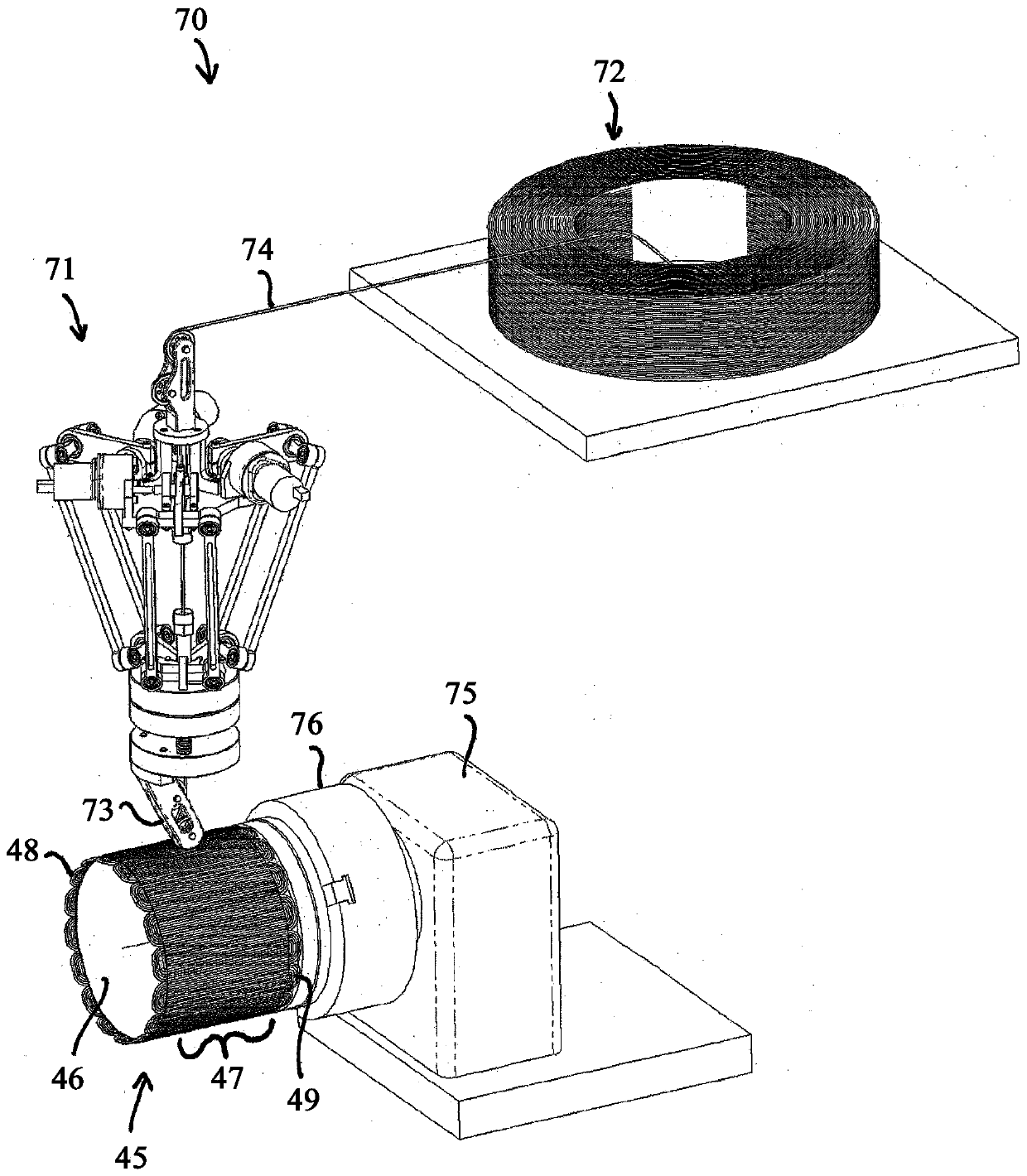

[0030] Turning to the drawings, wherein like reference numerals indicate like or corresponding parts, figure 1 A hollow core motor generator 30 comprising a rotor 31 and a stator 32 is shown. The rotor 31 consists of two concentrically spaced apart steel rotor columns 33 , 34 which are attached to a hub 35 . The hub 35 is supported by a central shaft 36 which is journaled for rotation by bearings 37 , 38 . Bearings 37 , 38 are mounted in housing end plates 39 , 40 which are connected together by an outer housing tube 41 . Attached to the rotor tubes 33, 34 are circumferential alternating polarity permanent magnet arrays 42, 43 which drive magnetic flux back and forth between the rotor tubes 33, 34 and an armature gap 44 formed between the rotor tubes. Positioned within the armature void 44 is a hollow armature 45 which is attached to the stationary housing end plate 39 . The hollow armature 45 consists of a non-magnetic form tube 46 that extends into the armature void 44 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com