A kind of high-strength high-modulus epoxy resin composition and its preparation method and application

A technology of epoxy resin and composition, which is applied in the field of thermosetting resins, can solve the problems of adverse effects of resin and composite materials on moisture and heat resistance, high cost, cumbersome preparation steps, etc., and achieves suitable for large-scale preparation, low cost, and wide source of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] (5) Preparation of epoxy resin composition

[0063] Add all the epoxy components into the stirring disperser and heat to 90°C to stir and mix evenly. After adding the thermoplastic resin modifier, continue to heat up to 135°C and stir to dissolve evenly. Then cool down to 70°C and add the curing agent. Material, obtains described epoxy resin composition.

[0064] (6) Preparation of prepreg

[0065] Use coating equipment to coat the epoxy resin composition prepared by above-mentioned (5) on the release paper, make a resin film, and then laminate the film on the carbon fiber (product model T800SC-24K, Japan Toray Co.) on both sides, heat and press with a hot roller at a temperature of 110° C. and 1 atmospheric pressure to fully impregnate the resin composition and carbon fibers (volume content 64%) to obtain a prepreg product.

[0066] (7) Performance testing of cured resin and composite materials

[0067] The bending performance of the cured resin is tested according ...

Embodiment 1

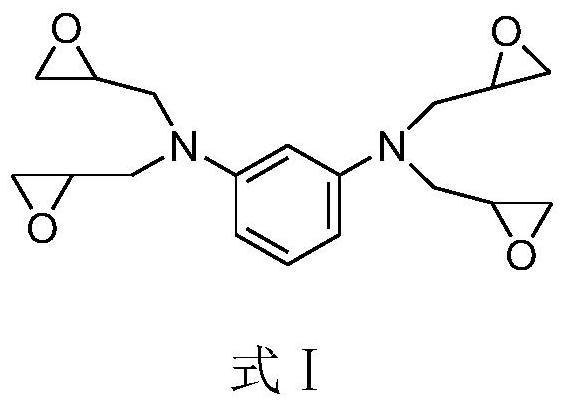

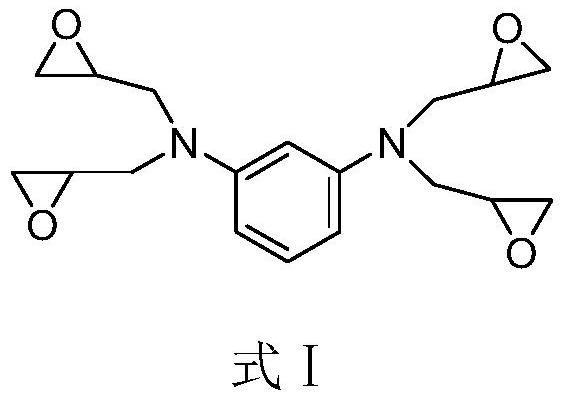

[0073] Add 100 parts by mass of m-phenylenediamine tetraglycidyl epoxy resin and 15 parts by mass of polyethersulfone into the stirring disperser, heat up to 135°C and stir to dissolve evenly, then cool down to 70°C and add 70 parts by mass of 3,3' - diaminodiphenyl sulfone, stirring and dispersing evenly before discharging to obtain an epoxy resin composition.

Embodiment 2

[0075] Add 100 parts by mass of m-phenylenediamine tetraglycidyl epoxy resin and 50 parts by mass of p-aminophenol triglycidyl epoxy resin into the stirring disperser and heat to 90°C to stir and mix evenly, then add 22.5 parts by mass of poly For ether sulfone, heat up to 135°C and stir to dissolve evenly, then cool down to 70°C and add 100 parts by mass of 3,3'-diaminodiphenylsulfone, stir and disperse evenly, then discharge to obtain an epoxy resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com