Internal heating type vacuum drying bin

A vacuum drying and internal heating technology, which is applied to non-progressive dryers, heating devices, and drying solid materials, can solve the problems of low effective use of heat energy, low heat exchange efficiency of heat energy, uneven drying moisture, etc., to achieve drying The effect of improving moisture uniformity and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

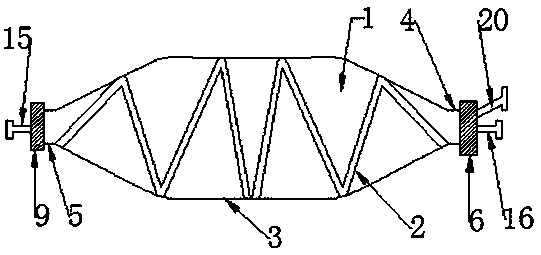

[0057] Such as figure 1 The shown internal heating type vacuum drying bin includes a heating type spiral blade 2, a feeding device 6, a discharging device 9, and a drum drying bin 1.

[0058] The drum drying bin 1 has an inlet 4 and an outlet 5 on it.

[0059] The outer diameter of the drum drying chamber 1 is 1800 mm; the length of the drum drying chamber 1 is 8000 mm.

[0060] The material of the cylinder body 3 of the drum dryer 1 is a metal plate, and the thickness of the metal plate is 2 mm.

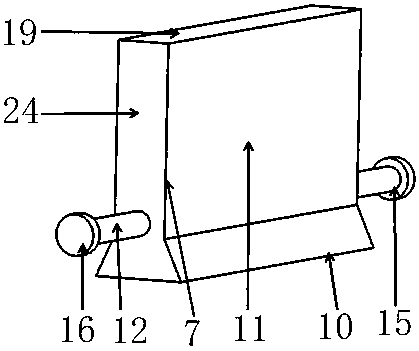

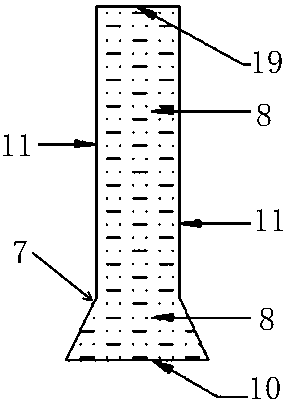

[0061] Such as figure 1 , Figure 4 The shown feeding device 6 includes a discharge valve 17, an elbow 21, a flange joint 13, a sealing device 14, a hopper 18, an exhaust pipe 20, and a dynamic sealing device 25; the dynamic sealing device 25 is fixed on the elbow 21.

[0062] The exhaust pipe 20 is fixed on the elbow 21, and the exhaust pipe 20 and the elbow 21 are fixedly connected as a whole; the inside of the exhaust pipe 20 and the inside of the elbow 21 are ventilated, and the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com