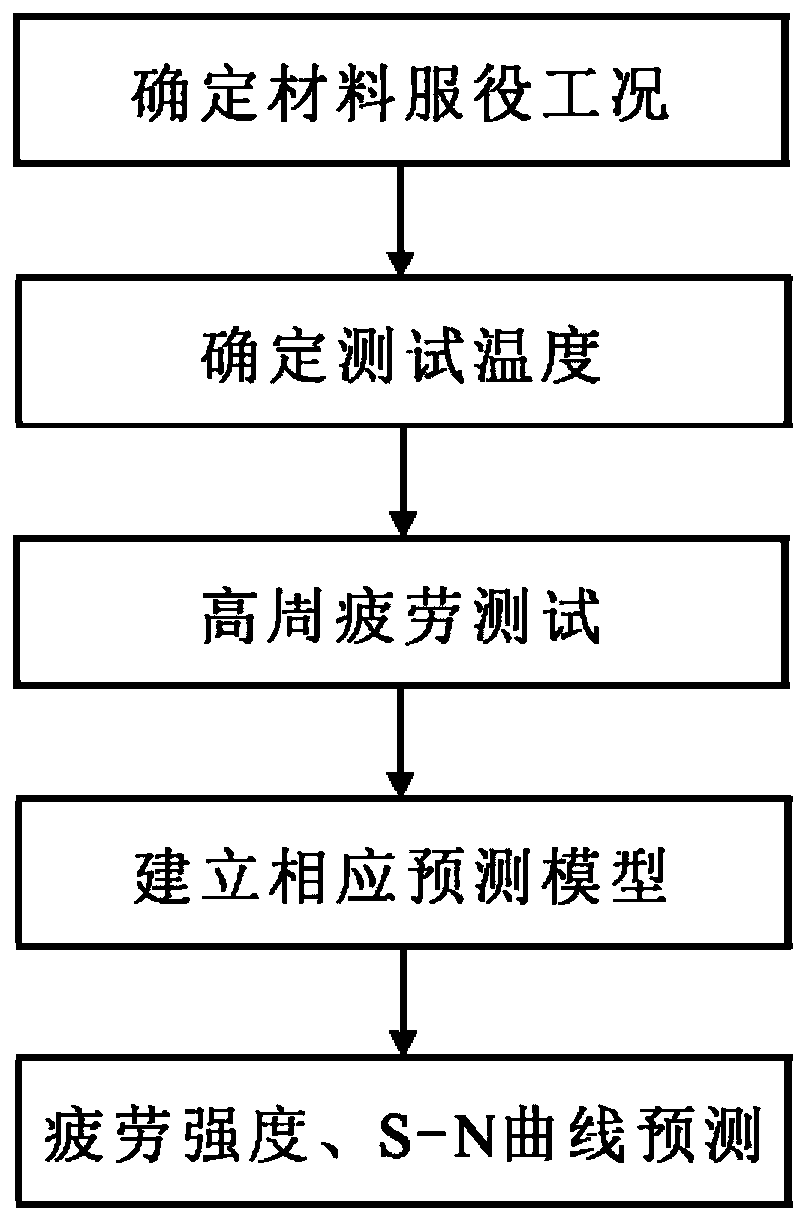

Prediction method for high-cycle fatigue performance of metal material under different temperature conditions

A technology of high cycle fatigue and temperature conditions, applied in the fields of instrumentation, calculation, electrical and digital data processing, etc., can solve the problems of reducing the service safety of components, increasing the service cost of components, and laboriousness, reducing the test volume requirement and high applicability. , the effect of good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

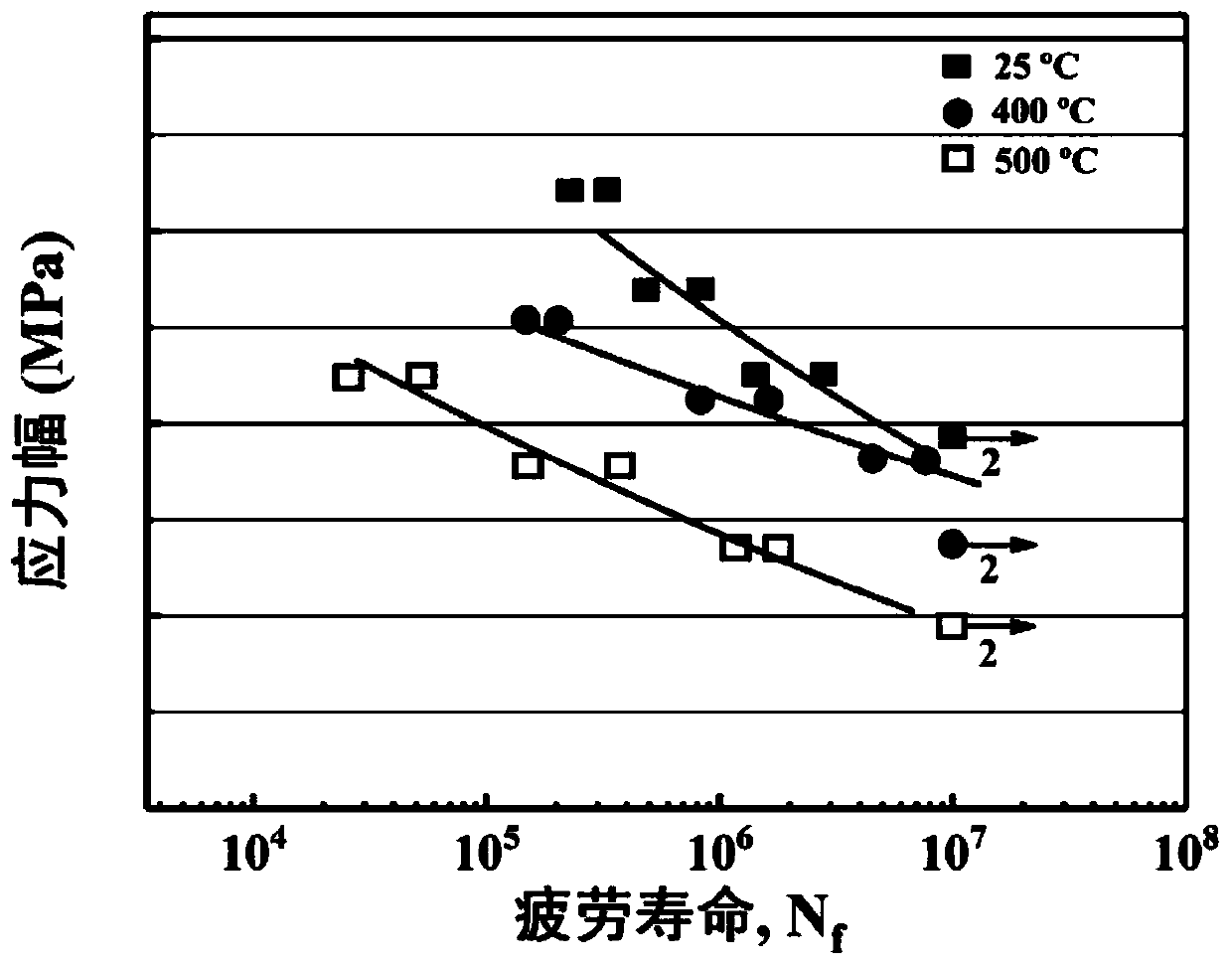

[0046] This embodiment is to predict the performance of vermicular graphite cast iron material in high cycle fatigue working condition, the specific process is as follows:

[0047] First, the vermicular graphite cast iron material is taken from the diesel engine cylinder head, and the temperature range of the high-cycle fatigue condition is determined to be 25 (room temperature)-500°C according to the service condition.

[0048]Second, choose three typical temperatures: 25, 400 and 500°C; the fatigue strength test method chooses the lifting method, the stress amplitude increase and decrease is 10MPa, and the fatigue test is in accordance with GB / T 3075-2008 Metal material fatigue test axial force control method The calculation of fatigue strength is carried out according to the statistical scheme and analysis method of fatigue test data of metal materials in GB / T24176-2009. The schematic diagrams of three typical temperature S-N curves are as follows: figure 2 .

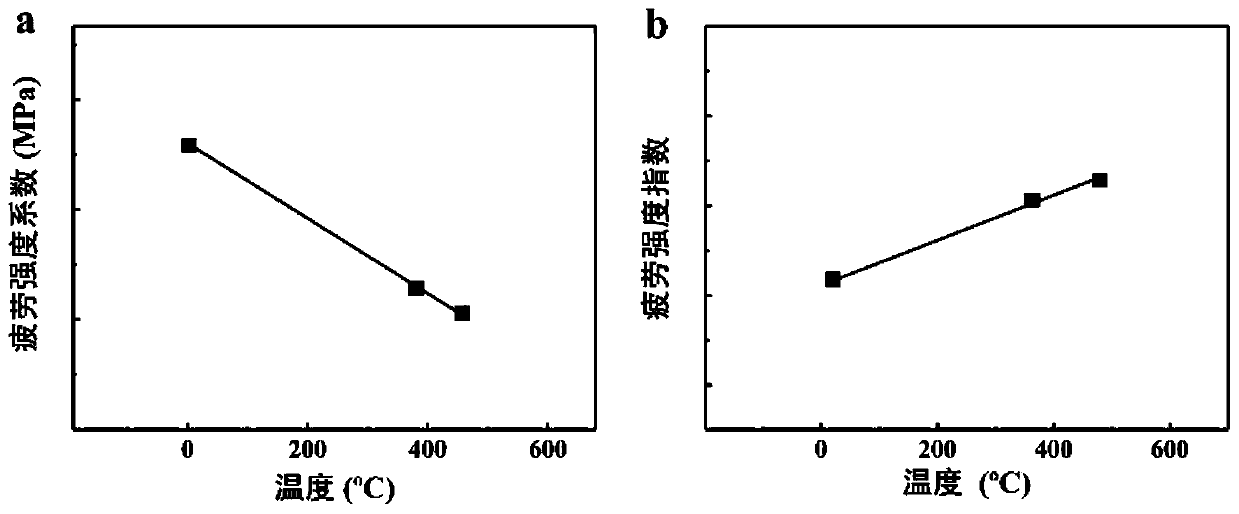

[0049] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com