Metal/gamma-Graphene composite model and method for modifying electronic performance of gamma-Graphene

A composite model and metal technology, applied in the field of materials science, can solve the problems of introducing impurities, unable to guarantee the purity of graphdiyne, and defects of graphdiyne, and achieve the effects of high accuracy, simple operation and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] According to the above-mentioned technical solution, this embodiment provides a metal / γ-Graphyne composite model and a method for modifying the electronic properties of γ-Graphyne, and the metal used is Al(111) plane. The specific steps are:

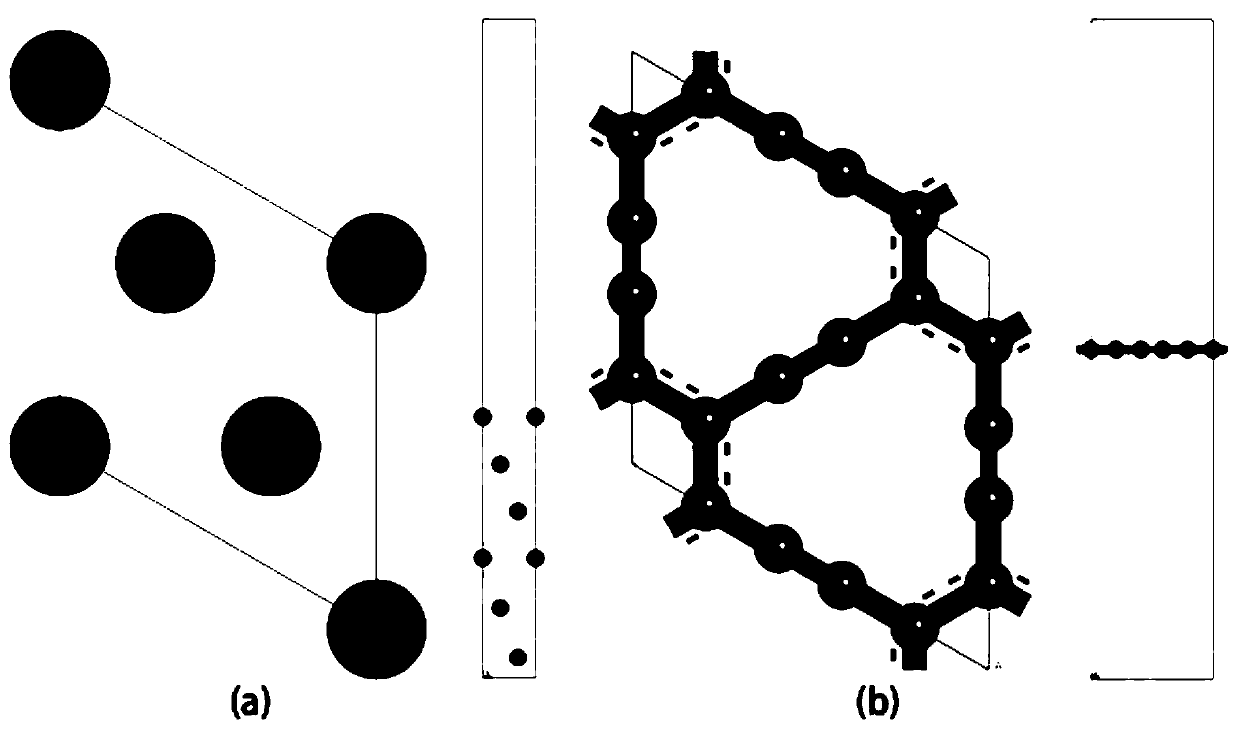

[0038] Step 1: Use Material Studio 17.1 to build a 6-layer Al(111) surface unit cell model and a γ-Graphyne unit cell model for Al and γ-Graphyne, see figure 1 , and then use the parameters obtained from the convergence test: the K point value is 6×6×1, the cut-off energy E cutoff is 400eV, using this parameter to optimize the structure of the 6-layer Al(111) plane unit cell model and the γ-Graphyne unit cell model, and obtain the 6-layer Al(111) plane unit cell model and the atomic total internal energy The lowest γ-Graphyne unit cell model;

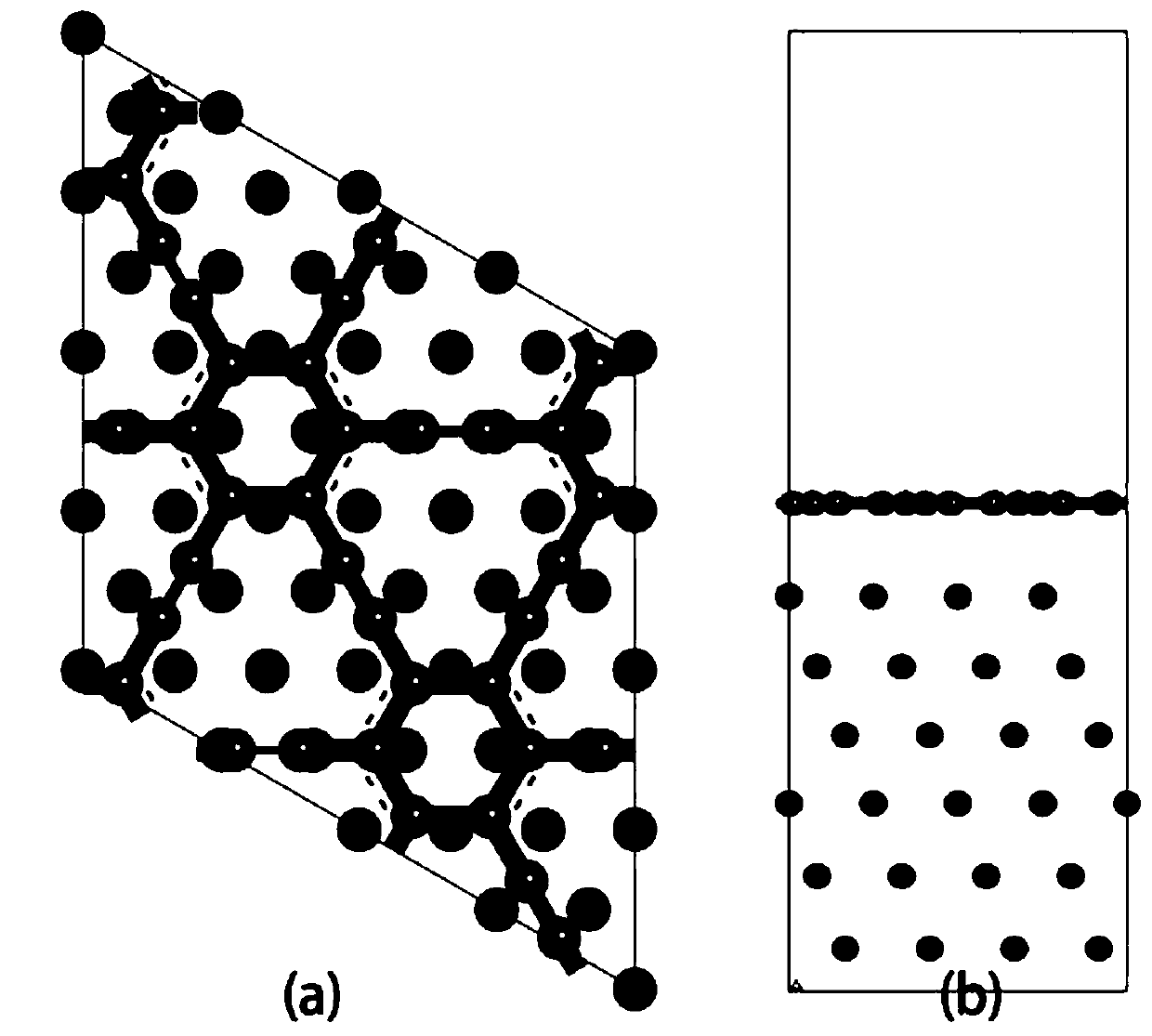

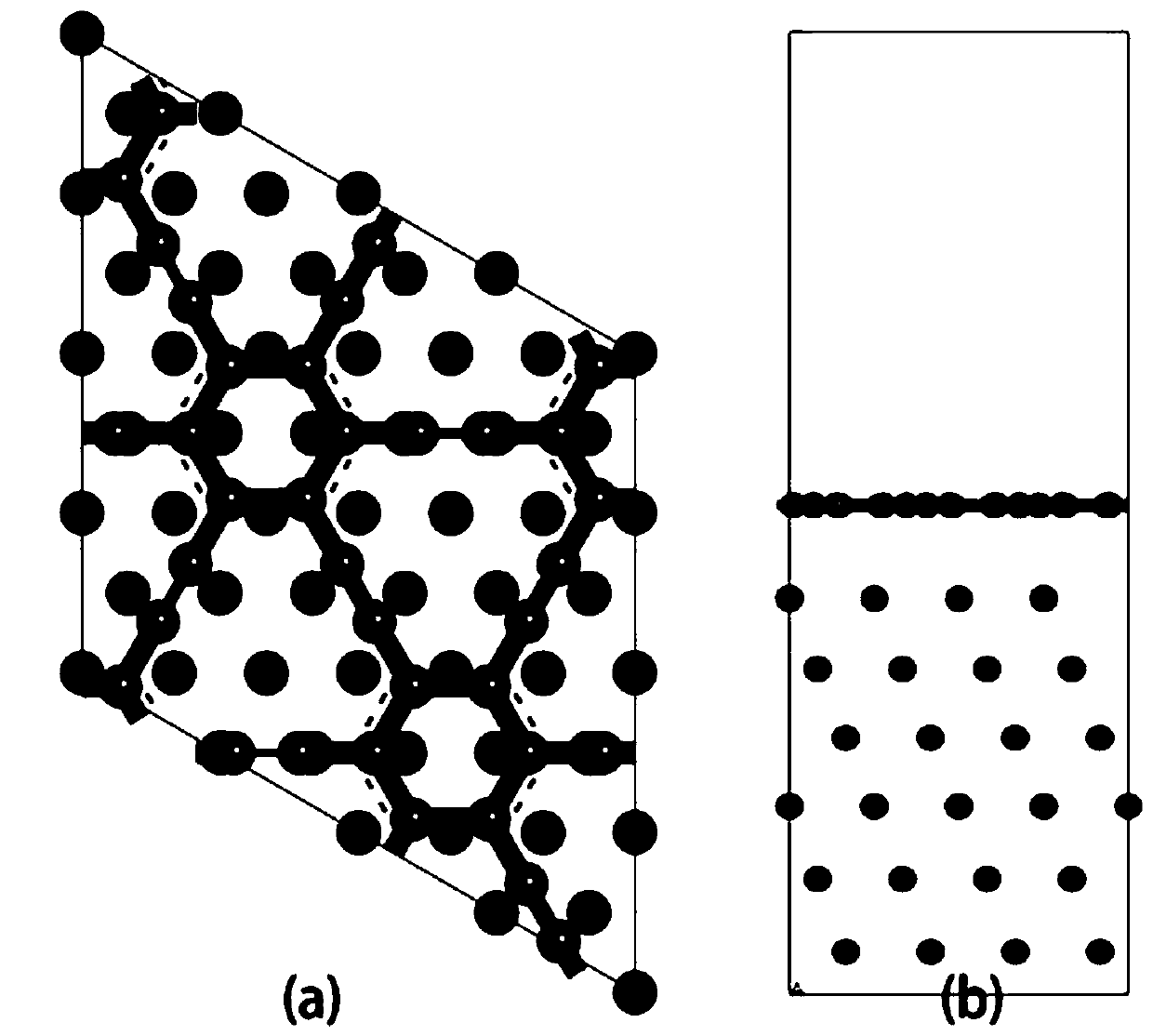

[0039] Step 2: Use the 6-layer Al(111) plane unit cell model with the lowest atomic total internal energy and the γ-Graphyne unit cell model with the lowest atomic total internal energy t...

Embodiment 2

[0047] According to the above-mentioned technical solution, this embodiment provides a metal / γ-Graphyne composite model and a method for modifying the electronic properties of γ-Graphyne, and the metal used is Ag. The specific steps are:

[0048] Step 1, use Material Studio 17.1 to build a 6-layer Ag(111) surface unit cell model and a γ-Graphyne unit cell model for Ag and γ-Graphyne respectively, see figure 1 , and then use the parameters obtained from the convergence test: the K point value is 6×6×1, the cut-off energy E cutoff is 400eV, using this parameter to optimize the structure of the 6-layer Ag(111) plane unit cell model and the γ-Graphyne unit cell model, and obtain the 6-layer Ag(111) plane unit cell model with the lowest total internal energy of the atom and the total internal energy of the atom The lowest γ-Graphyne unit cell model;

[0049] Step 2: Use the 6-layer Ag(111) surface unit cell model with the lowest atomic total internal energy and the γ-Graphyne uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com