Multi-layer circuit board machining method

A processing method and multi-layer circuit technology, applied in the direction of multi-layer circuit manufacturing, printed circuit, printed circuit manufacturing, etc., can solve the problems of high processing cost, many repeated processes, and many times of pressing, so as to improve production efficiency and reduce Manufacturing cost, effect of reducing the number of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

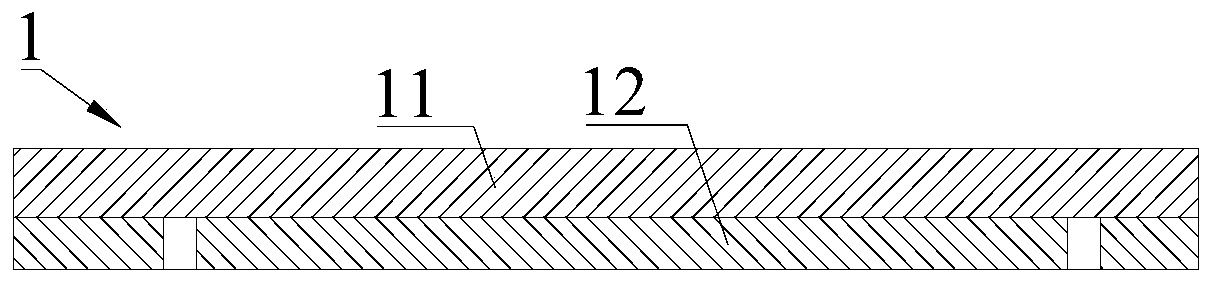

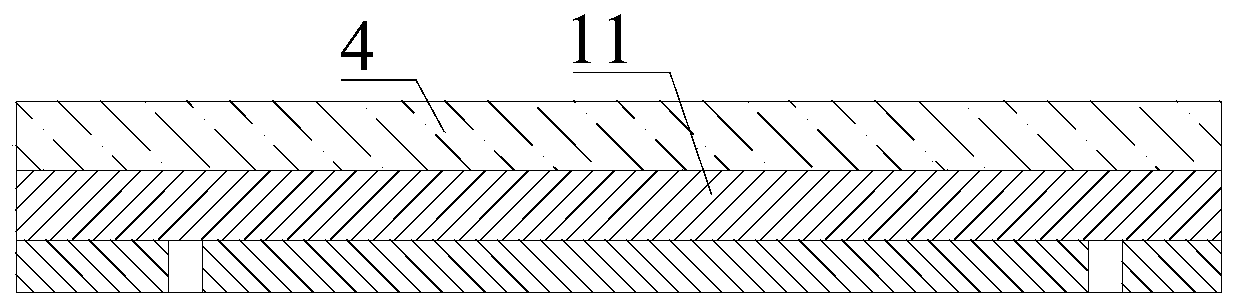

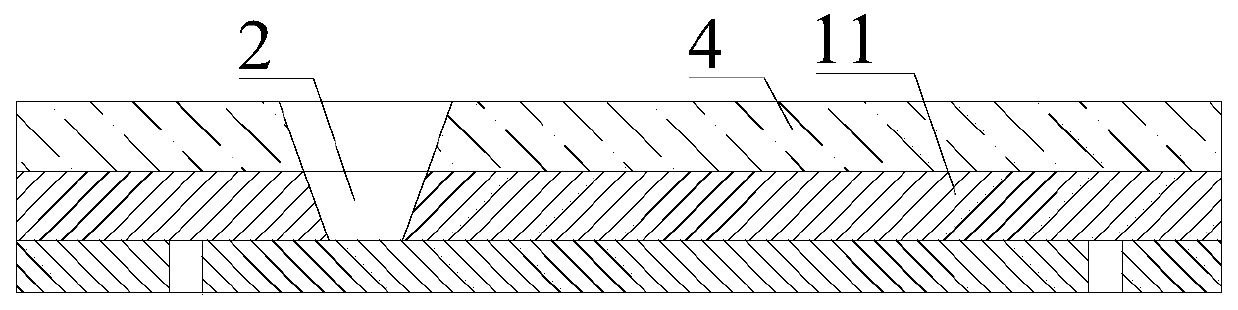

[0039] Please refer to Figure 1 to Figure 6 , Embodiment one of the present invention is: multilayer circuit board processing method, comprises the following steps,

[0040] S1. Make preset circuits for each plate 1 respectively;

[0041] S2. Stack each plate 1 in a preset order to obtain a stack of plates;

[0042] S3. Laminating the sheet stack at one time to obtain a multilayer circuit board.

[0043] In step S1 , making the preset circuit includes opening a via hole 2 , and step S11 before step S2 includes printing conductive paste 3 into the via hole 2 . The conductive paste 3 is used to connect two adjacent boards 1 . The via hole 2 can be a through hole or a blind hole. It should be understood that there may be individual boards 1 that do not need to be connected to other boards 1 , so the conduction holes 2 do not need to be opened on the individual boards 1 . The conductive paste 3 may be copper paste or the like.

[0044] Preferably, in step S1, when opening t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com