Three-dimensional orthodontic retainer and method for producing a three-dimensional orthodontic retainer

A retainer, three-dimensional technology, applied in manufacturing tools, additive manufacturing, orthodontics, etc., can solve problems such as weakening materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

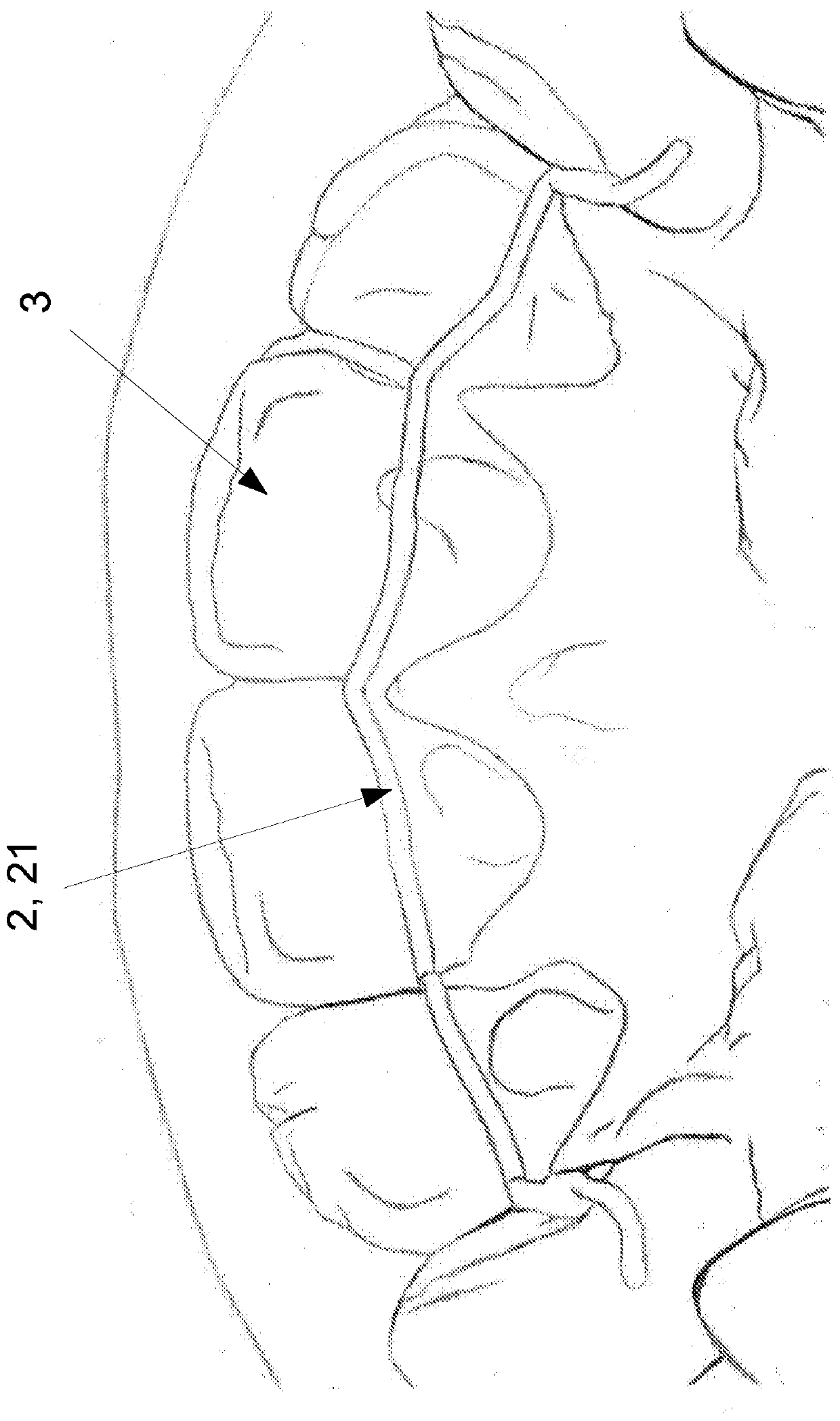

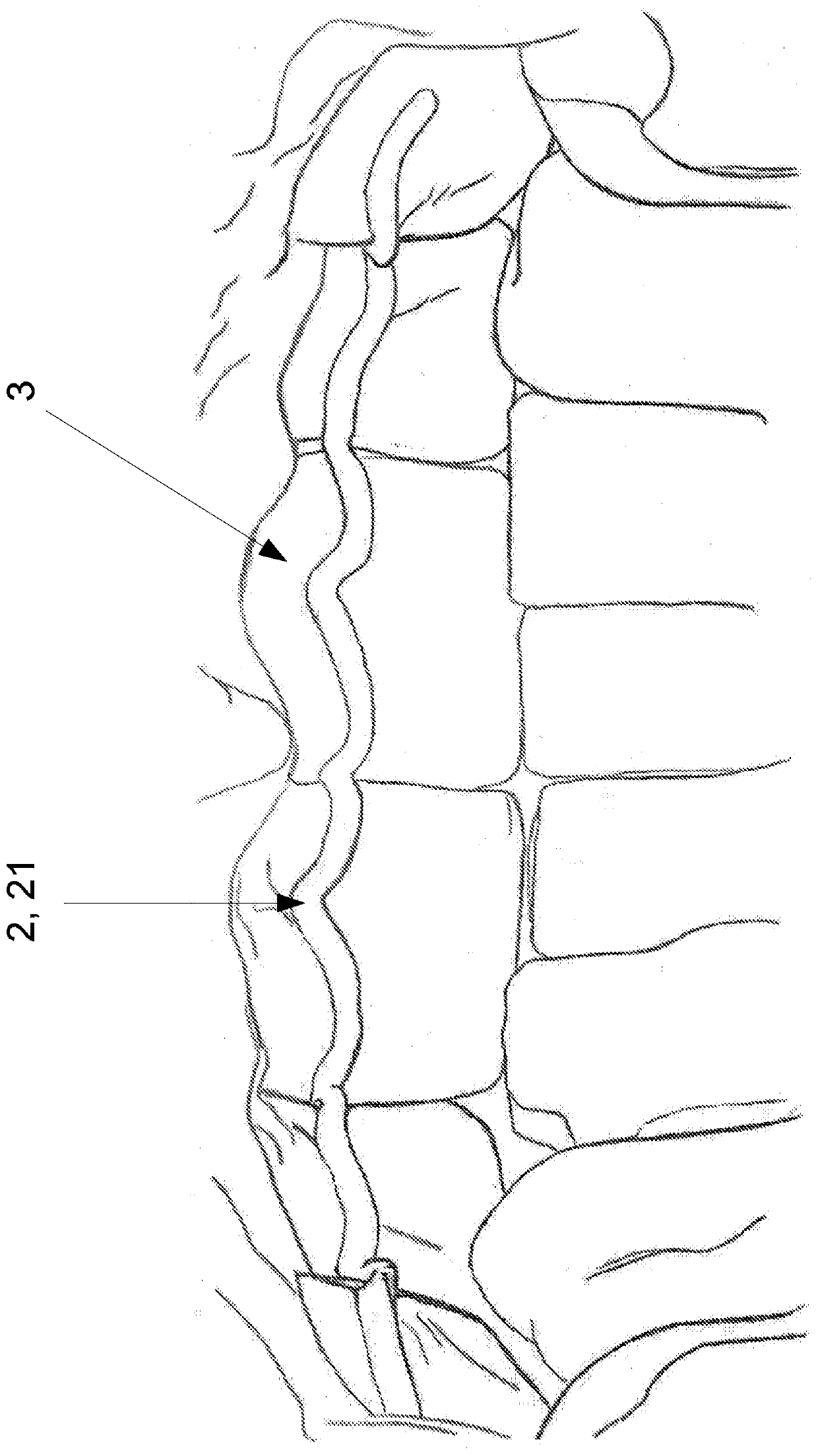

[0014] For the production of the three-dimensional orthodontic retainer ( 2 ) according to the invention, a biocompatible material is preferably used as starting material, which furthermore contains as little allergen as possible. For example metals, metal alloys such as Ti-Mo or Ti-6AL-4V (GR5 ELI titanium alloy, used in medical technology), ceramic materials (eg zirconium), plastics or any combination of these materials are suitable. In order to avoid problems for the wearer, it can also be taken into account that the original material does not contain materials such as nickel, which are known to cause allergic reactions. The present holder ( 2 ) is produced from a raw material ( 1 ), for example in the form of a blank ( 1 ). The blank (1) can have any shape as long as it is large enough to machine the holder (2) from it. It is not necessary for the existing surface of the blank (1) to correspond to the machined sides of the holder (2), since a precisely fitting shape of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com